Leading line self-walking dangerous chemicals raw material barrel and working method thereof

A self-propelled, raw material barrel technology, applied in the direction of preventing mechanical damage to containers, containers, packaging, etc., can solve the problems of no anti-collision buffer capacity, the impact of raw materials in the barrel, and the mixing of raw material barrels into the storage area, etc., to reduce damage Possibility, avoiding unstable properties, and the effect of chemical production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

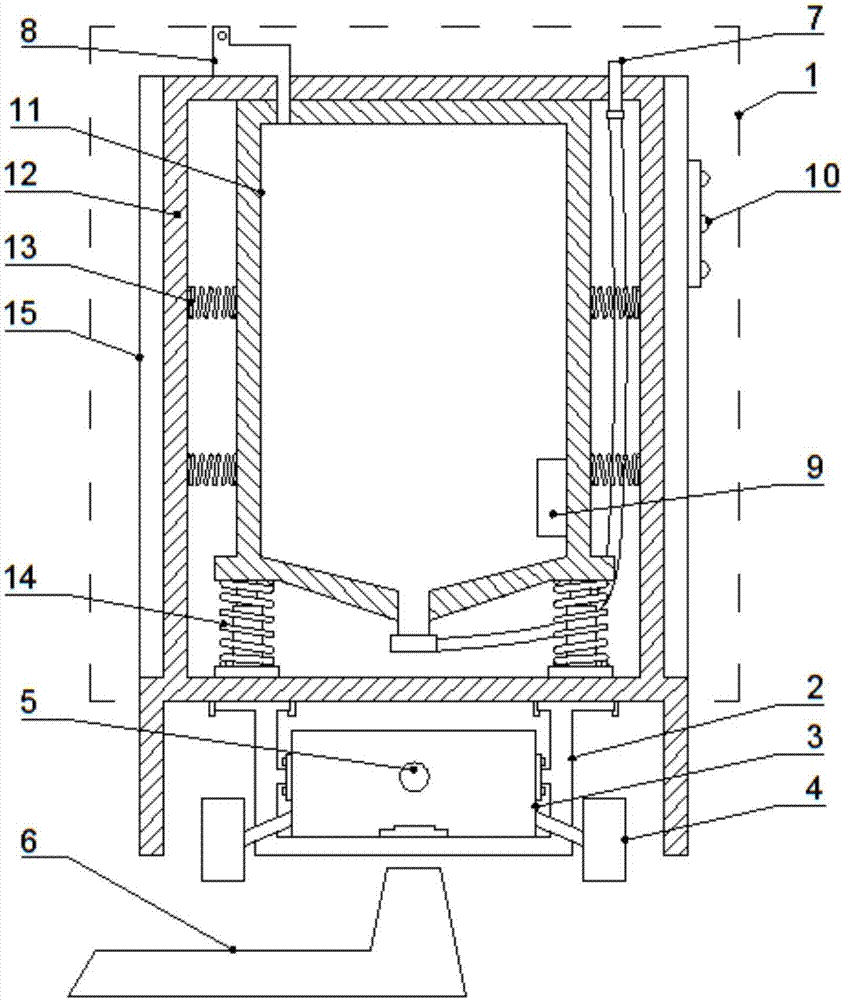

[0037] Such as figure 1 A guide line self-propelled dangerous chemical raw material barrel is shown, which is characterized in that it includes: a housing 1 and a running mechanism, the lower end of the housing 1 is provided with a running mechanism; the running mechanism includes a support frame 2, a control Power box 3, running wheel 4, color sensor 5 and guide strip 6, the support frame 2 is arranged at the lower end of the housing 1, and the control power box 3 is arranged inside the support frame 2, and the two sides of the control power box 3 A running wheel 4 is provided, a color sensor 5 is provided at one end of the power box 3, and the guide strip 6 is provided on the ground.

[0038] The housing 1 described in this embodiment includes an inner container 11, an outer shell 12, a shock absorbing spring 13, a shock absorber 14, and an anti-collision rubber 15. The outer shell 12 is arranged on the bottom plate 3, and the inner shell 12 is provided with Inner tank 11, ...

Embodiment 2

[0046] Such as figure 1 The working method of a self-propelled dangerous chemical raw material barrel with a guide line is shown, which is characterized in that: the walking mechanism relies on the color sensor 5 to identify the guide sticker 6 on the ground to move to a predetermined position; Step 1: Arranging guide stickers 6, the guide stickers 6 include normal raw material circuit stickers, problematic raw material circuit stickers and dangerous raw material circuit stickers; Step 2: start the traveling mechanism, and the microprocessing chip selects the corresponding color according to the response of the detection mechanism 9 Step 3: The traveling mechanism travels to a predetermined position according to the guide sticker 6 detected by the color sensor 5 .

[0047] A method for selecting a guide line self-propelled dangerous chemical raw material barrel described in this embodiment is characterized in that: none of the sensors in the detection mechanism 9 responds, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com