Preparation method of modified rubber, the modified rubber, and bulletproof and puncture-proof tyre

A modified rubber, bulletproof and stab-proof technology, which is applied in the preparation of modified rubber, modified rubber and bulletproof and puncture-proof tires, which can solve the problems of heavy weight and poor driving stability of bulletproof tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

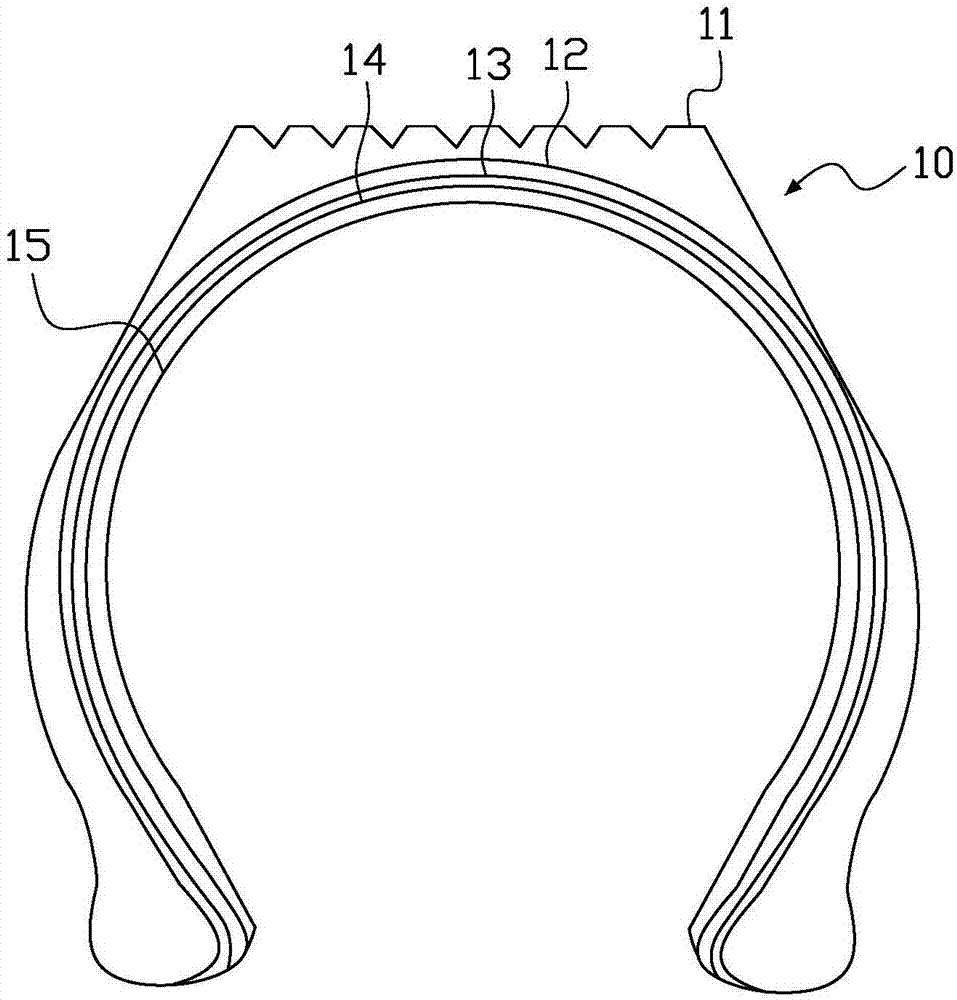

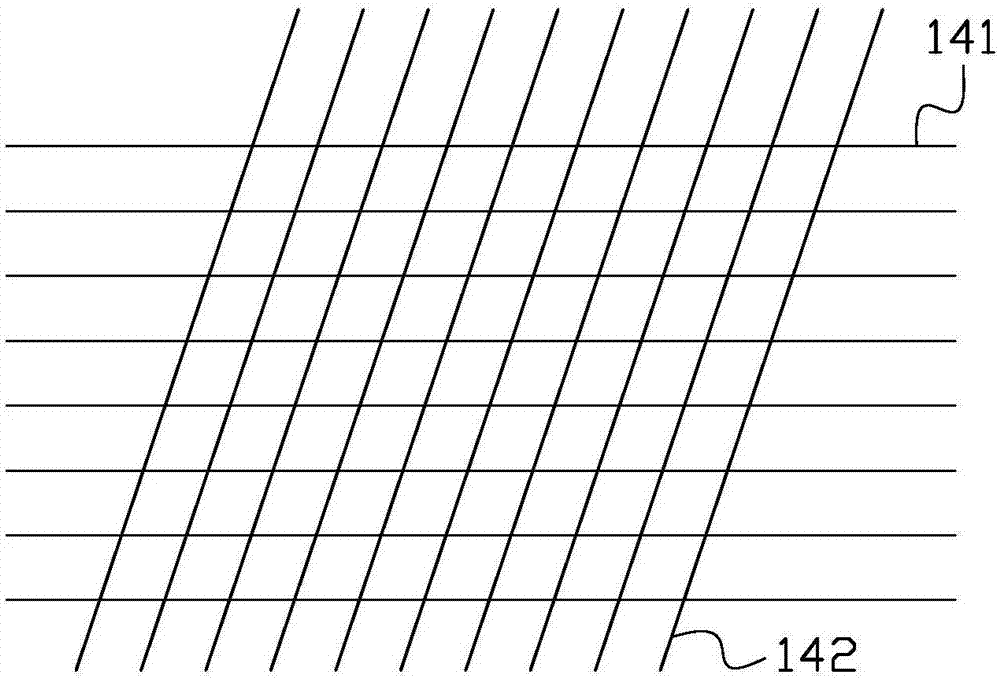

[0017] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0018] The invention provides a kind of preparation method of modified rubber, comprising steps:

[0019] After irradiating high-performance short fibers under ultraviolet light for a period of time, add them to ethanol, and make a uniformly dispersed fiber suspension by stirring;

[0020] Add a coupling agent to the prepared fiber suspension, adjust the pH to 8-9, react at room temperature for 2-4 hours, then add sodium dodecylbenzenesulfonate, and continue to react for 1-2 hours to obtain a reaction solution. Suction filtration under reduced pressure to remove the liquid in the reaction solution to obtain the modified fiber slurry;

[0021] Adding the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com