Alloy material for manufacturing motor rotor and preparation method thereof

A technology of alloy materials and motor rotors, applied in the field of motor manufacturing, can solve the problems of deterioration of mechanical properties, difficulty in processing and assembling iron cores, etc., and achieve the effects of improving efficiency, solving excessive loss, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

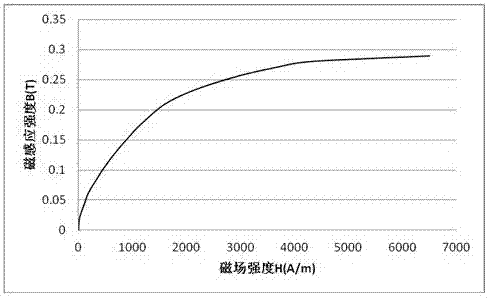

Image

Examples

Embodiment 1

[0027] An alloy material used to manufacture motor rotors, calculated by weight percentage, its raw material composition and content are as follows:

[0028] Copper 95%

[0029] Iron 5%.

[0030] The above-mentioned method for preparing an alloy material for manufacturing a motor rotor, the specific steps are as follows:

[0031] (1), melting

[0032] First, the raw materials copper and iron are placed in a melting furnace for smelting. The temperature of the alloy liquid obtained after smelting is controlled at 1500-1550°C and kept for 20-30 minutes, and then the temperature of the alloy liquid is reduced to 250°C under the isolation of nitrogen, and then again Carry out heating up to 800°C;

[0033] (2), casting

[0034] Control the temperature of the alloy liquid obtained in step (1) to 800°C in the ladle for constant temperature casting. In order to ensure the quality of the casting, enough gates should be left;

[0035] (3), quenching treatment

[0036] After consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com