Method and device for eliminating rust on surface of strip steel

A technology for removing strips and steel strips, which is applied in the field of cold rolling and pickling, and can solve the problems of scrapping of small coils of strip steel and rust spots on the surface of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In order to fully understand the method of this article, first introduce the process equipment of the pickling production line. The equipment mainly includes: 1# looper, the first deviation correction roller, the first tension roller, the tension leveler, the second tension roller, and the pickling tank , rinsing tank, dryer, second tension roller, second correction roller and 2# looper. Then the strip passes through the above equipment sequentially during the acid rolling process.

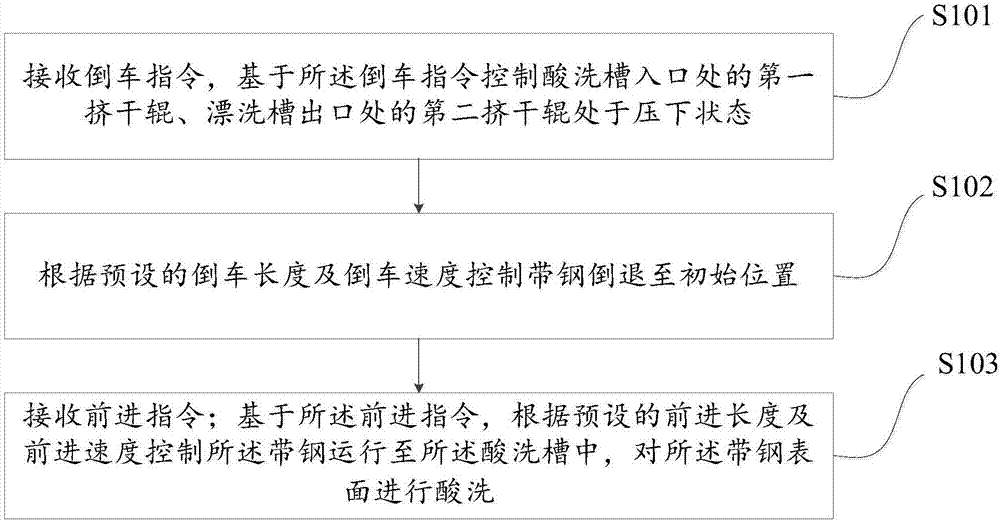

[0033] Correspondingly, this embodiment provides a method for eliminating corrosion on the surface of strip steel, which is applied to the above-mentioned pickling production line, such as figure 1 As shown, the method includes:

[0034] S101, receiving a reversing instruction, and controlling the first wringing roller at the entrance of the pickling tank and the second wringing roller at the exit of the rinsing tank to be in a depressed state based on the reversing instruction;

[0035] ...

Embodiment 2

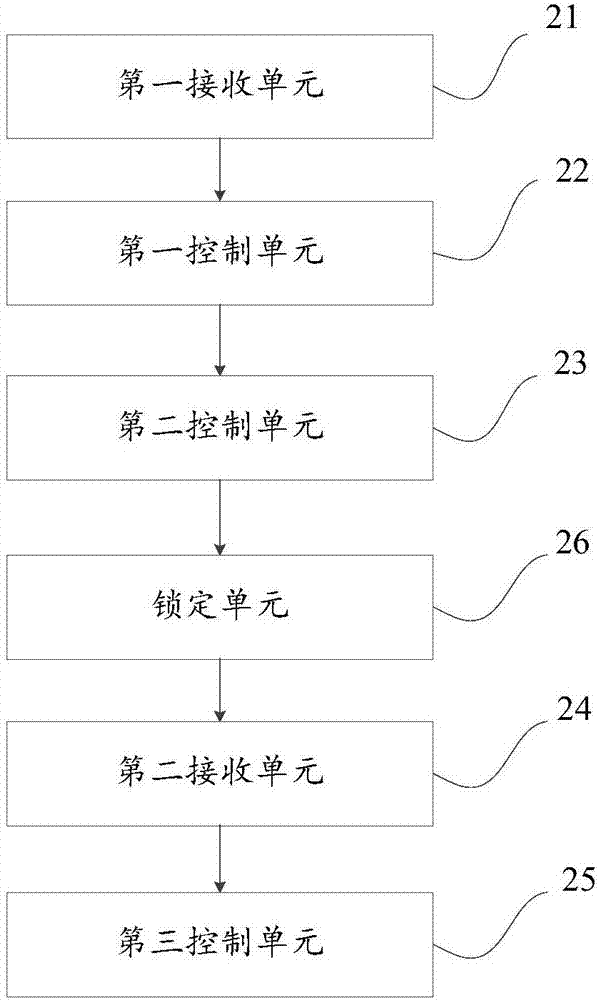

[0047] Corresponding to Embodiment 1, this embodiment also provides a device for eliminating corrosion on the surface of strip steel, such as figure 2 As shown, the device includes: a first receiving unit 21, a first control unit 22, a second control unit 23, a second receiving unit 24, and a third control unit 25; wherein,

[0048] After the first receiving unit 21 receives the reversing instruction, the first control unit 22 is also used to It is judged whether the pickling production line has the conditions for reversing. If it is determined that the conditions for reversing are met, the first squeezing roll at the entrance of the pickling tank and the second squeezing roll at the exit of the rinsing tank are controlled based on the reverse command to be in a depressed state. A control message for controlling the first squeezing roller and the second squeezing roller is written in the reversing command.

[0049] The reversing conditions may include: the amount of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com