Multi-module structure and its connection method for 3D box-type assembled light steel structure

A light steel structure, prefabricated technology, applied in building structure, construction and other directions, can solve the problems of installation errors, construction conditions, self-heavy, unguaranteed welding quality, etc., and achieve the reduction of structural steel consumption and the degree of industrialization High and fast construction effect

Inactive Publication Date: 2019-06-07

苏州智绿建筑工程有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1) The existing container module system adopts new or waste containers to form the main structure, the structure size is single, and the wall based on the corrugated board is not ideal in terms of lighting, ventilation and heat preservation;

[0004] 2) The hot-rolled section steel system uses welding to form various components into a frame structure with a container shape. This structural system uses a large number of welding constructions, and the welding quality cannot be guaranteed. In addition, inert gases will be generated during the welding process, which will affect health and pollute surroundings;

[0005] 3) Both the container and the hot-rolled section steel system have self-heavy problems, which will cause inconvenience in transportation and hoisting;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

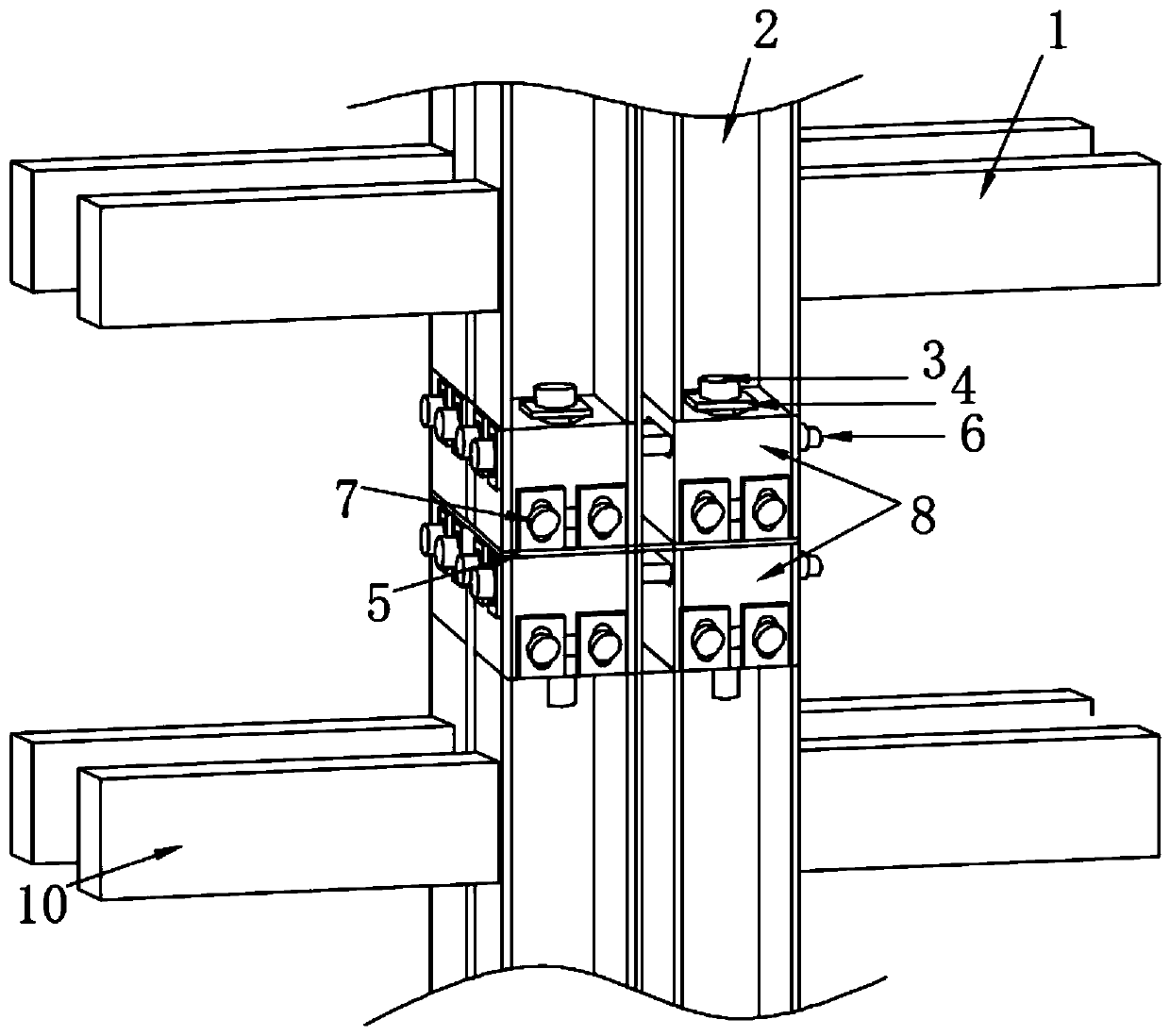

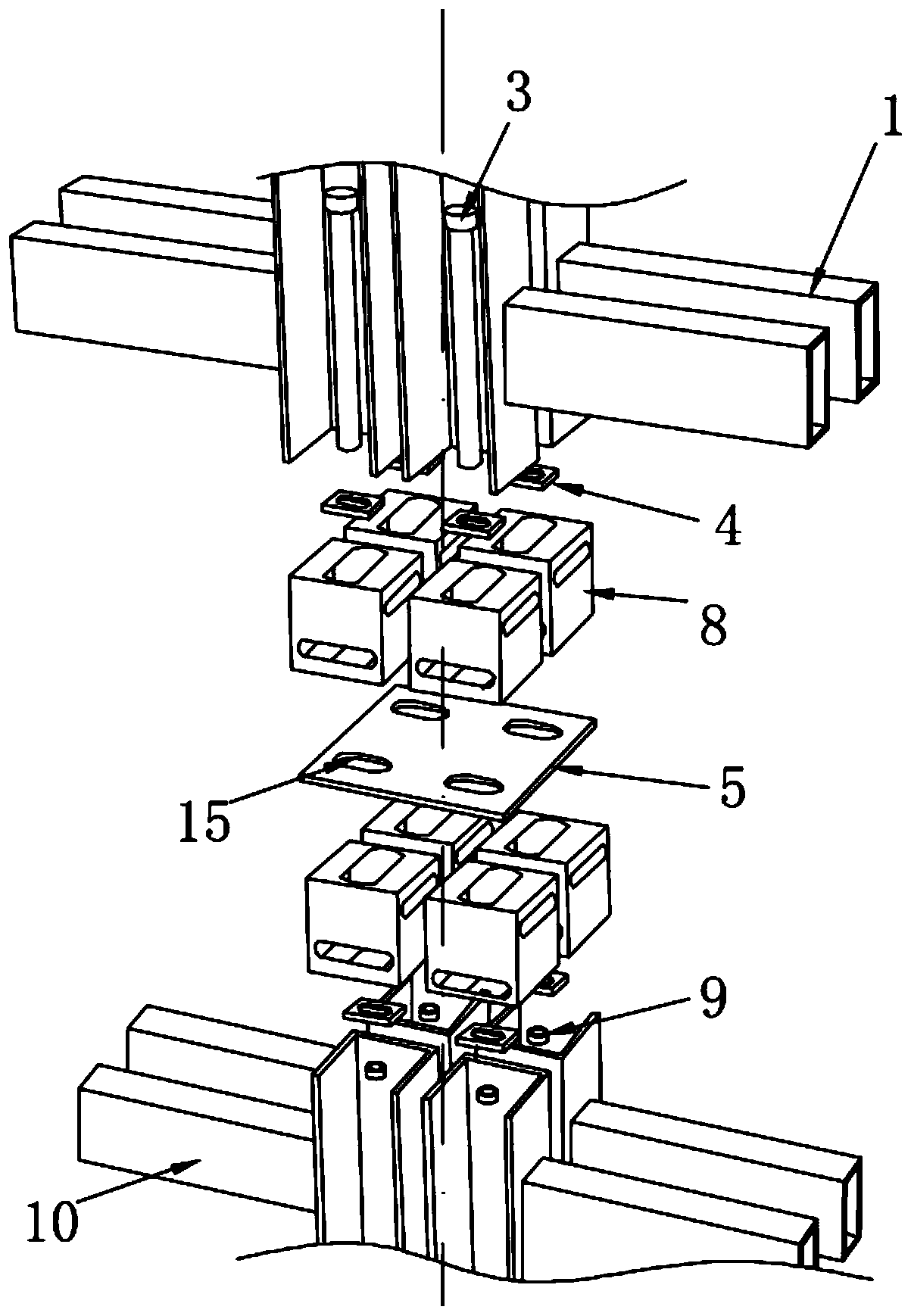

[0048] see Figure 5 , the angle steel 2, the upper guide rail 1, the lower guide rail 10 and the corner fittings 8 in this embodiment are all welded by hot-rolled section steel to form a frame module. Connectors and self-tapping screws are used to connect between frame modules, and the above-mentioned structure and construction steps are used to complete the connection between frame modules.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

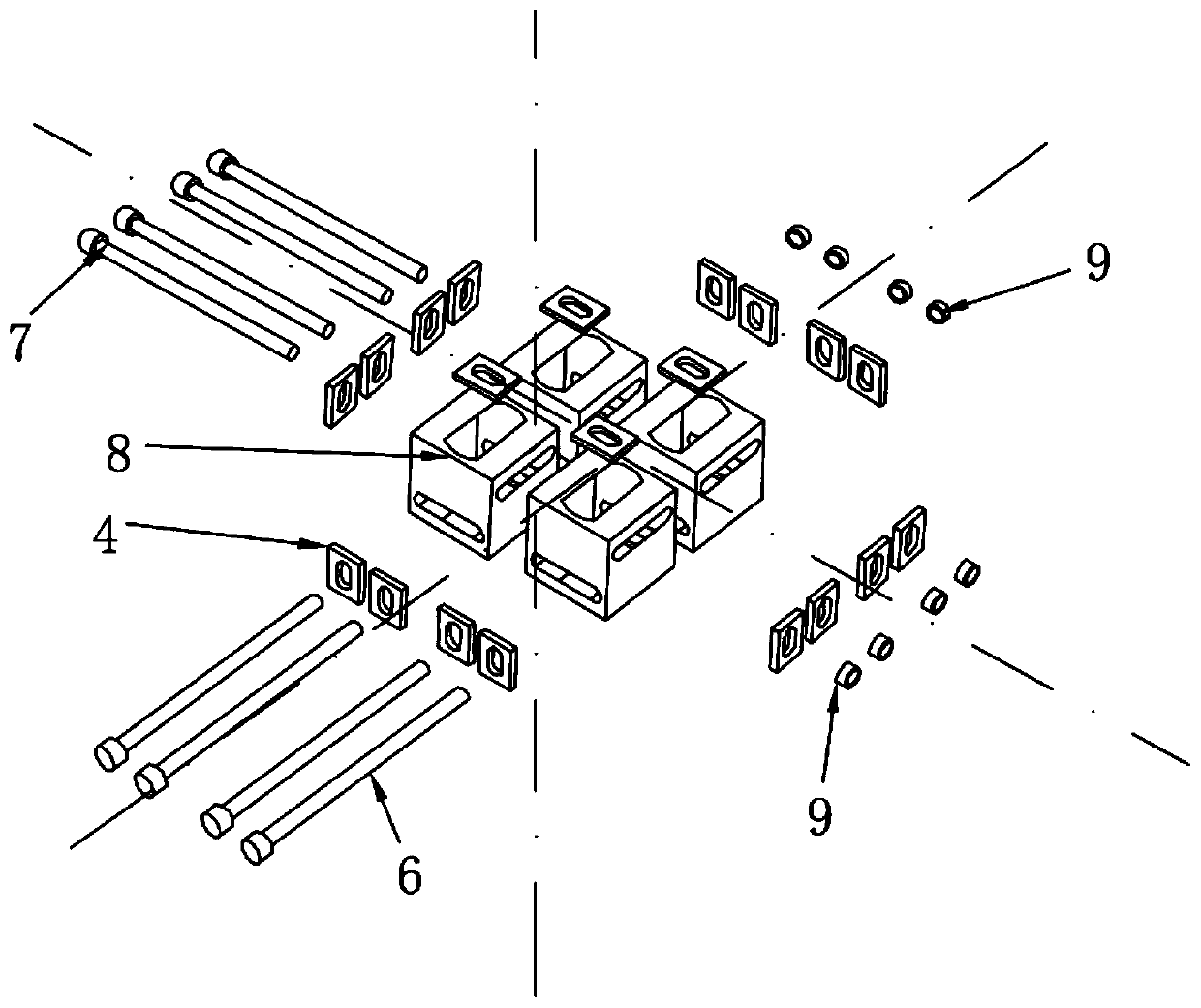

The invention discloses a multi-module structure for a three-dimensional box-type fabricated lightweight steel structure and a connecting mode thereof and relates to the technical field of construction. Upper guide rails, corner columns and lower guide rails form frame modules, and the frame modules are connected through corner parts, vertical bolts, horizontal bolts, longitudinal bolts and connecting plates. The corner parts are welded at the upper ends and the lower ends of the corner columns, and the connecting plates are arranged between the corner parts of upper and lower layers of frame modules. The longitudinal bolts sequentially penetrate through pad plate limiting holes located on the same layer pad plates, front and rear holes of the corner parts at the lower ends of the corner columns in the front, front and rear holes of the corner parts at the lower ends of the corner columns in the back and pad plate limiting holes formed in the pad plates and then are connected and fixed through nuts. Interior decoration work can be completed in a factory, the structure steel amount is obviously reduced, and meanwhile members are light and convenient, so that the multi-module structure is quicker to install. A lightweight steel wall can be changed according to the change of room opening requirements and building size, convenience is brought to installation of heat insulation layers and line pipelines, and the factorization degree and construction speed are high.

Description

technical field [0001] The invention relates to the technical field of construction, in particular to a multi-module structure for a 3-dimensional box-type assembled light steel structure and a connection method thereof. Background technique [0002] The traditional modular structure system mainly includes container, section steel frame and light steel keel. Each of these systems has some limitations: [0003] 1) The existing container module system adopts new or waste containers to form the main structure, the structure size is single, and the wall based on the corrugated board is not ideal in terms of lighting, ventilation and heat preservation; [0004] 2) The hot-rolled section steel system uses welding to form various components into a frame structure with a container shape. This structural system uses a large number of welding constructions, and the welding quality cannot be guaranteed. In addition, inert gases will be generated during the welding process, which will a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04B1/348E04B1/24E04B1/58

CPCE04B1/2403E04B1/34807E04B2001/2406E04B2001/2418E04B2001/2421E04B2001/2433

Inventor 杨健范岩旻王斐亮王曈朱仁杰俞一舟袁中路

Owner 苏州智绿建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com