Door plate structure of box-type substation

A box-type substation and door panel technology, which is applied in the direction of door leaves, windows/doors, building components, etc., can solve the problems of low reuse rate, inconvenient processing and transportation of door panels, and unreachable problems, so as to facilitate processing and transportation, and improve repeatability The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

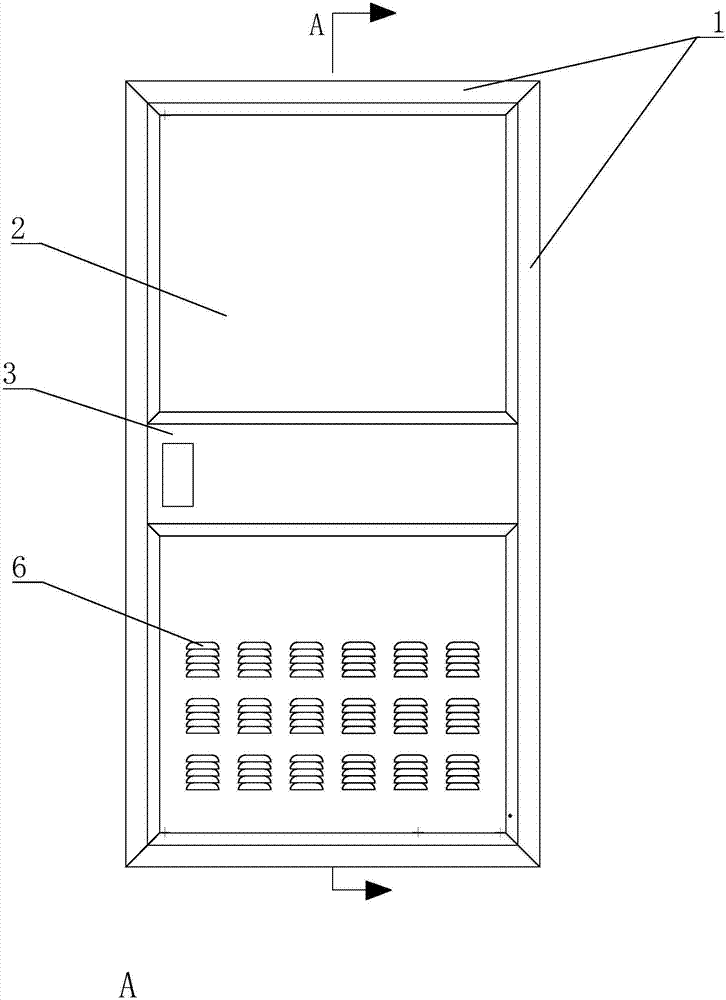

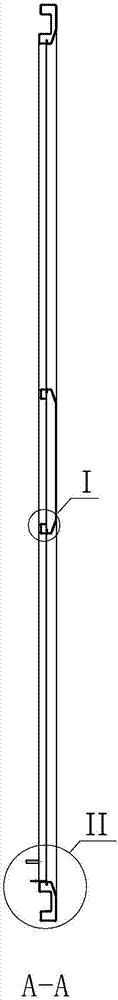

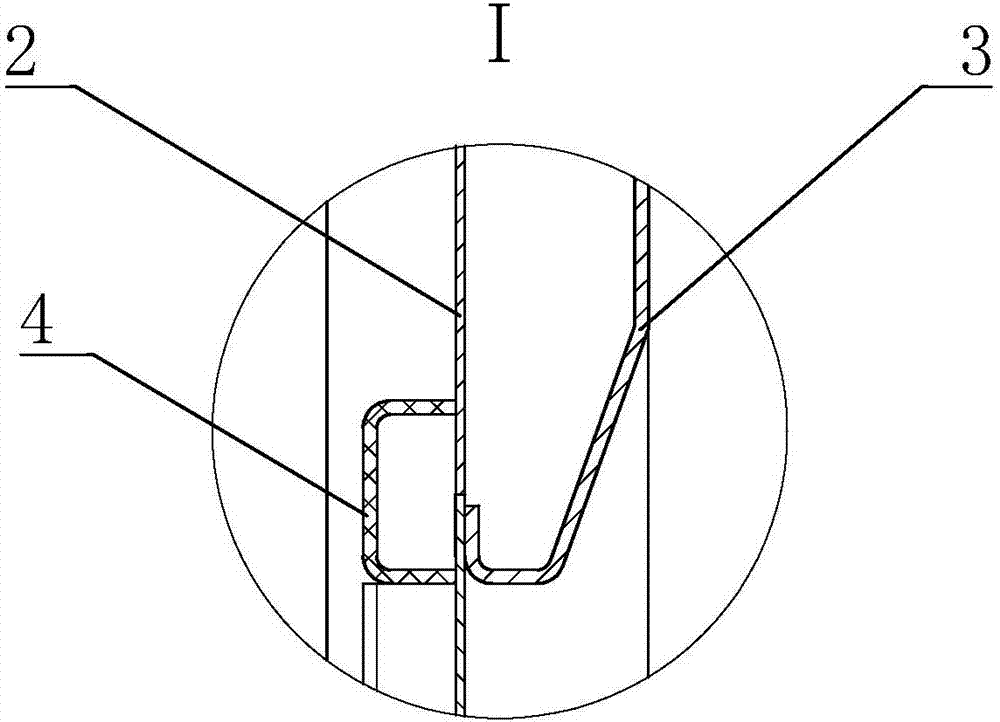

[0018] refer to Figure 1 to Figure 5 , a box-type substation door panel structure of the present invention, including a door panel and a door frame, the door frame is provided with a protruding outer door frame 1, the middle part of the outer door frame 1 is provided with a middle door frame 3, and the door panel includes a plurality of small door panels 2. The small door panel 2 is connected and fixed to the inner surfaces of the outer door frame 1 and the middle door frame 3, so that the installed door panel has a three-dimensional structure. Furthermore, spraying paints with different colors on the door panel makes the door panel structure more three-dimensional, so that it can better achieve the effect of being in harmony with the surrounding environment. In addition, the splicing of two small door panels improves the reusability of substation door panel materials. , to facilitate processing and transportation.

[0019] In this embodiment, the small door panels 2 are thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com