Construction method for repairing leaky river-crossing pipeline by utilizing air pressure system

A technology of air pressure system and construction method, applied in the direction of pipe components, pipes/pipe joints/pipes, water resources protection, etc., can solve the problems of high groundwater pressure, easy soil and water, unable to stop the trend of water leakage in cross-river pipelines, etc., to avoid leakage , to ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

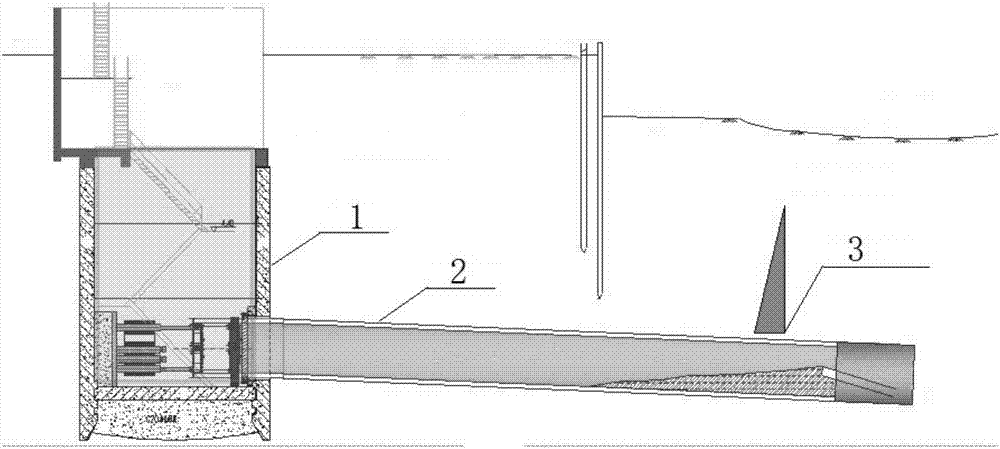

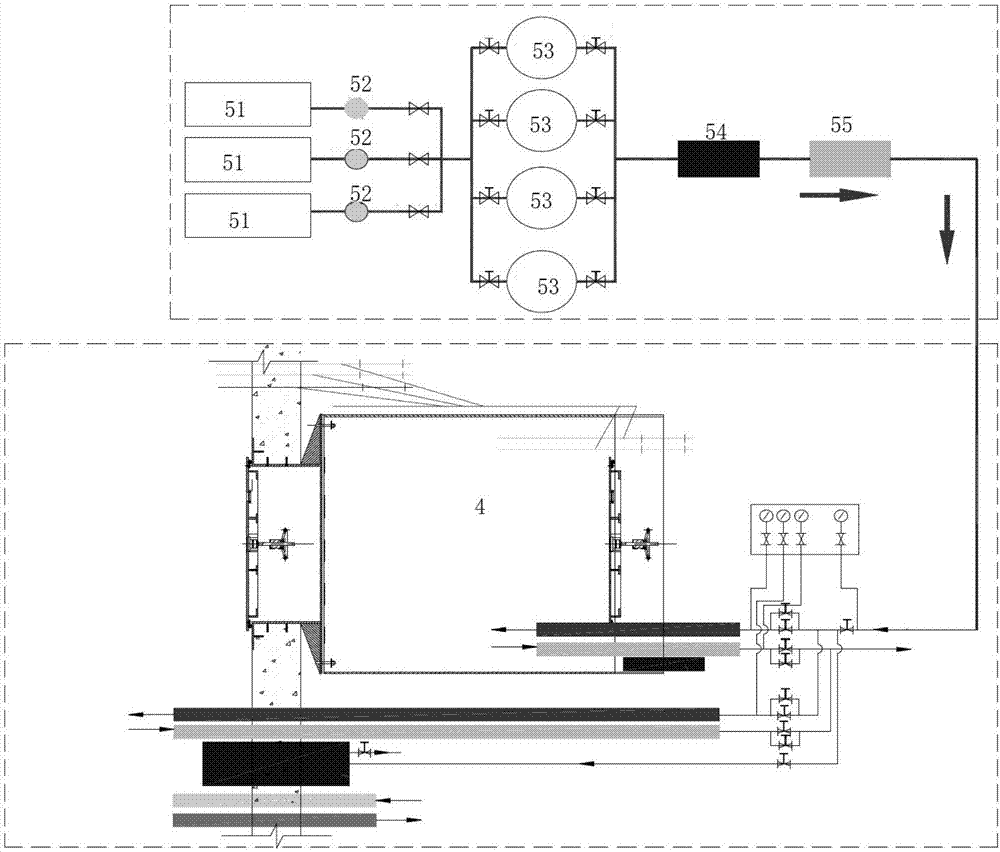

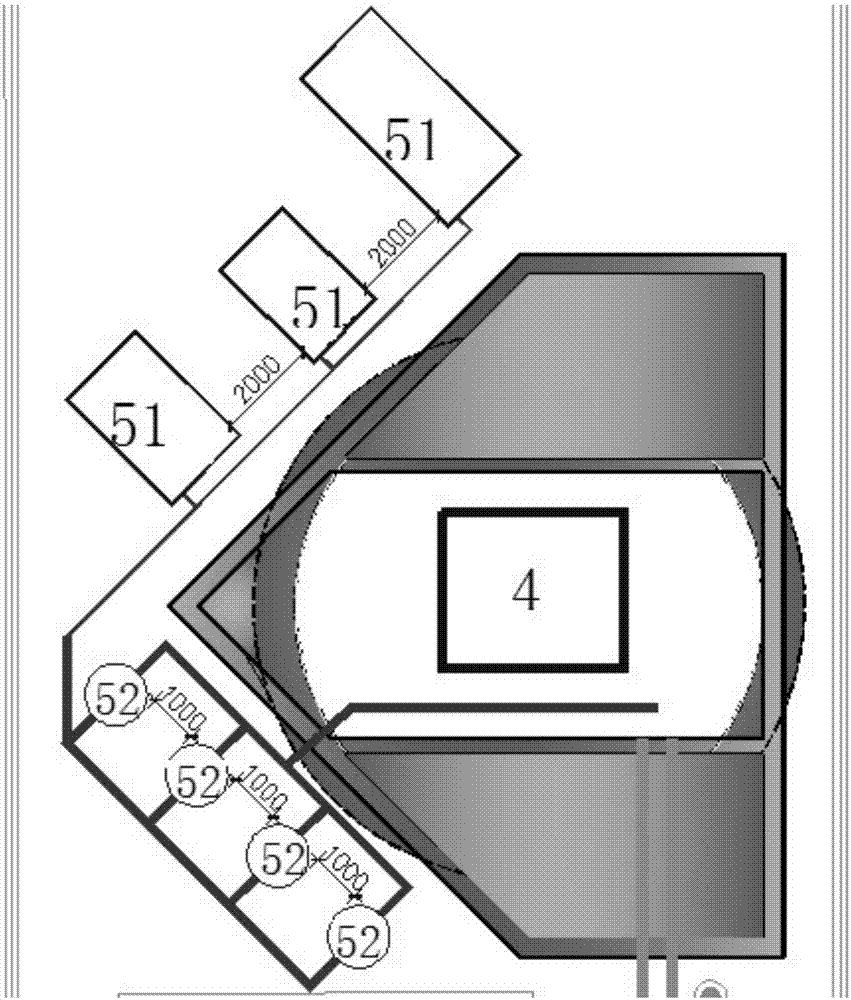

[0036] Such as figure 1 As shown, a preferred embodiment of the present invention provides a construction method for repairing a leaking cross-river pipeline using an air pressure system, which is characterized in that it includes the following steps:

[0037] Step 1. Inject water into the working well 1, so that the inside of the working well 1 and the pipeline 2 are filled with water; use the high water pressure inside the working well 1 to balance the water pressure difference at the leakage point 3 of the pipeline, thereby preventing the further entry of muddy water from the outside to the inside of pipe 2;

[0038] Step 2, establishing a sealed pressure chamber at the connection between the working well 1 and the pipeline; isolating the inside of the pipeline 2 from the outside world;

[0039] Step 3, pumping out the recharge water in the working well 1, injecting high-pressure gas into the inside of the pipeline 2 by utilizing the airtightness of the airtight pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com