Encircling-type heating boiler

A heating boiler, surround-type technology, applied in the boiler field, can solve the problems of slow boiler temperature rise, low fuel utilization rate, low heat energy conversion rate, etc., and achieve the effect of simple use, fast heating time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

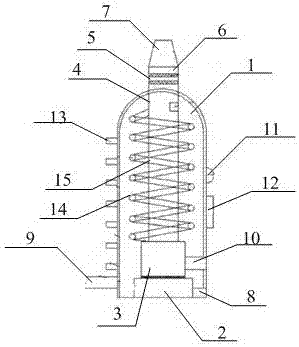

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] like figure 1 As shown, the boiler mechanism 1, the heating module 2, the exhaust base 3, the exhaust pipe 4, the filter layer 5, the retaining ring 6, the exhaust port 7, the fixed block 8, the fuel inlet 9, the air inlet 10, the indicator light 11, Control panel 12, screw 13, connection point 14, heat pipe 15.

[0013] A surrounding heating boiler, which includes a boiler mechanism 1 and a heating module 2, the heating module 2 is installed at the bottom of the boiler mechanism 1,

[0014] The boiler mechanism 1 includes a smoke exhaust base 3, a smoke exhaust pipe 4, a filter layer 5, a retaining ring 6, a smoke exhaust port 7, a fixing block 8, a fuel inlet 9, an air inlet 10, an indicator light 11, a control panel 12, screws 13, The connection point 14 and the heat pipe 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com