Apparatus of detecting sealing performance of low temperature liquid tank, and operation method of the same

A low-temperature liquid and detection device technology, which is applied in the test of fluid tightness, by detecting the appearance of fluid at the leakage point, measuring devices, etc., can solve the problems of increased maintenance costs, large helium consumption, and high helium price, and achieve Affordable, low manufacturing cost, easy to obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

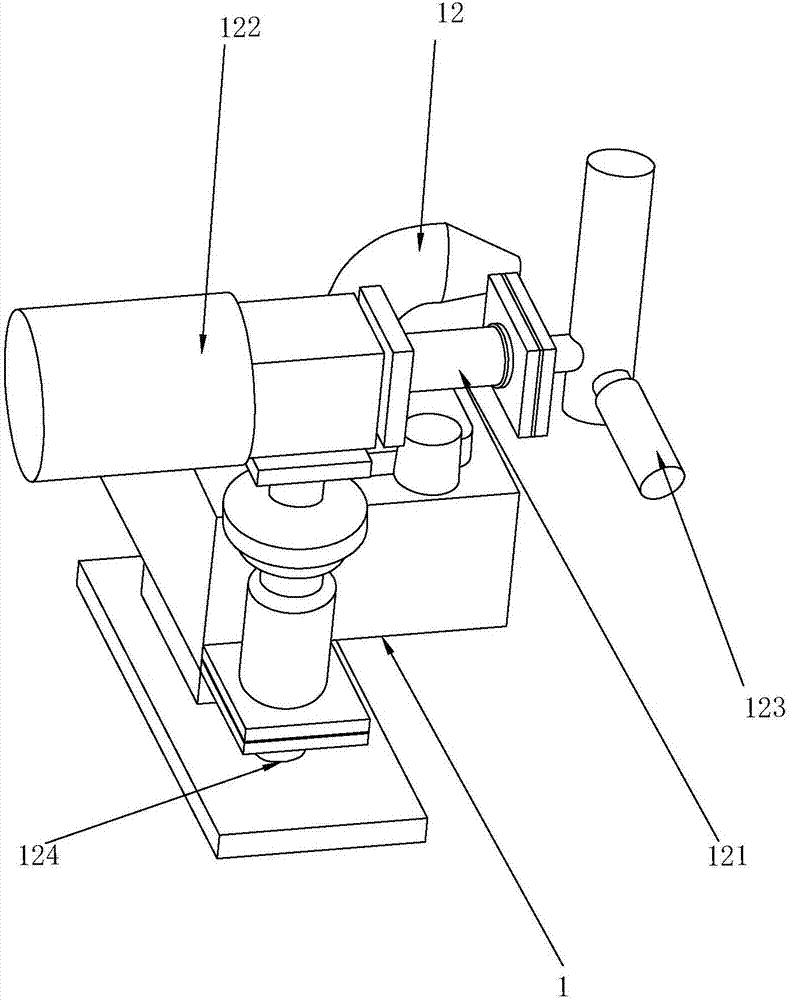

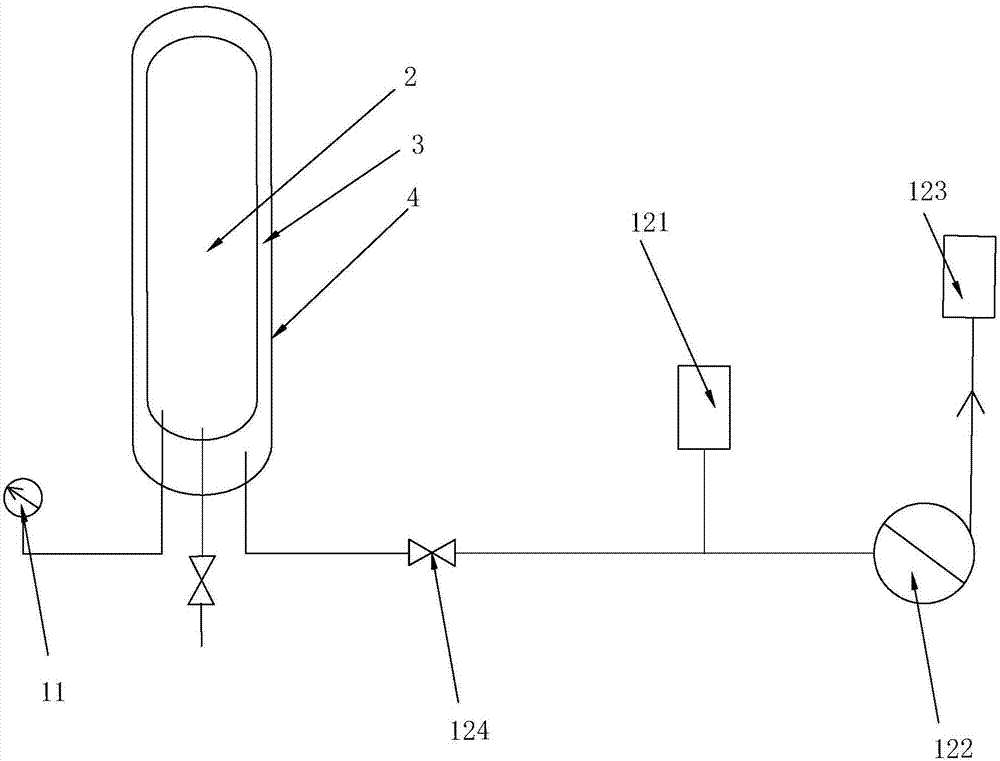

[0023] see figure 1 and figure 2 , a device for detecting the tightness of a low-temperature liquid tank according to the present invention, the low-temperature liquid tank includes an inner cylinder 2, an outer cylinder 4, and an interlayer 3 formed between the two, including a detection device body 1, and the detection device The main body 1 includes a pressure gauge 11 connected to the inner cylinder 2 and a vacuum group 12 that can be connected to the interlayer 3. The vacuum group 12 includes a vacuum gauge 121 for detecting the vacuum degree of the interlayer 3, and a vacuum gauge 121 to vent the air. A vacuum pump 122 connected to the end pipe, and an argon content detector 123 installed at the outlet end of the vacuum pump 122, a jacketed vacuum valve 124 is also connected between the vacuum gauge 121 and the interlayer 3, wherein the vacuum gauge 121 is a thermocouple vacuum The structure detected in this way is more sensitive; in addition, the vacuum pump 122 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com