Testing device and application of ultrahigh frequency sensor arrangement for gas-insulated combined switchgear

A combination technology of ultra-high-frequency sensors and gas insulation, which is applied to measuring devices, instruments, and testing dielectric strength, etc., can solve the problem of no relevant reports on sensors, and achieve good use effects, efficient test methods, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

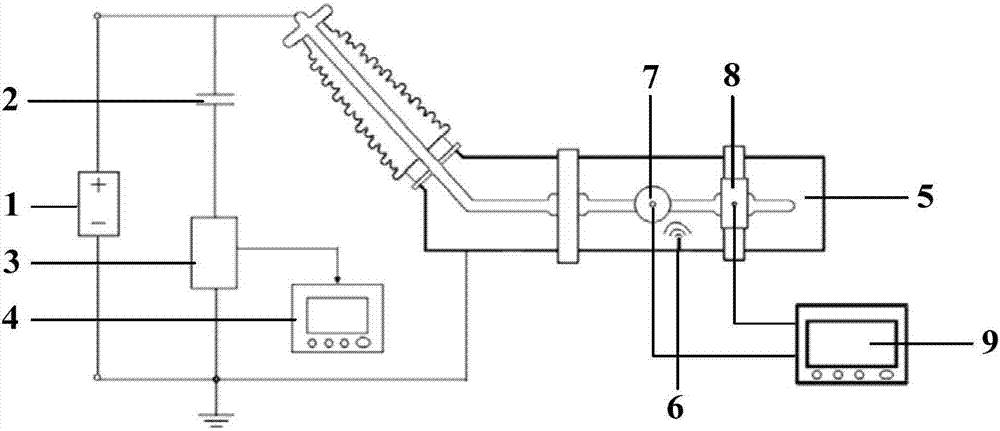

[0023] see figure 1 , the structural form of the UHF sensor layout test device for gas-insulated combined switchgear in this embodiment is: a non-PD voltage source 1, a coupling capacitor 2, a measuring impedance 3 and a PD instrument 4 according to the GB / T 7354-2003 standard "Partial Discharge Measurement" constitutes a partial discharge pulse current test platform; GIS model 5 is set, the positive terminal of the non-PD voltage source 1 is connected to the metal conductor in the GIS model 5, and the negative terminal of the non-PD voltage source 1 is connected to the GIS model 5 The shell is grounded; the artificial defect model 6 is placed in the GIS model 5, the built-in UHF sensor 7 and the external UHF sensor 8 are respectively set on the GIS model 5, and the built-in UHF sensor 7 and the external The output signal of the UHF sensor 8 is detected; the oscilloscope 9 uses Tektronix DPO70604B, which has four channels, 6GHz bandwidth, and 25G sampling rate.

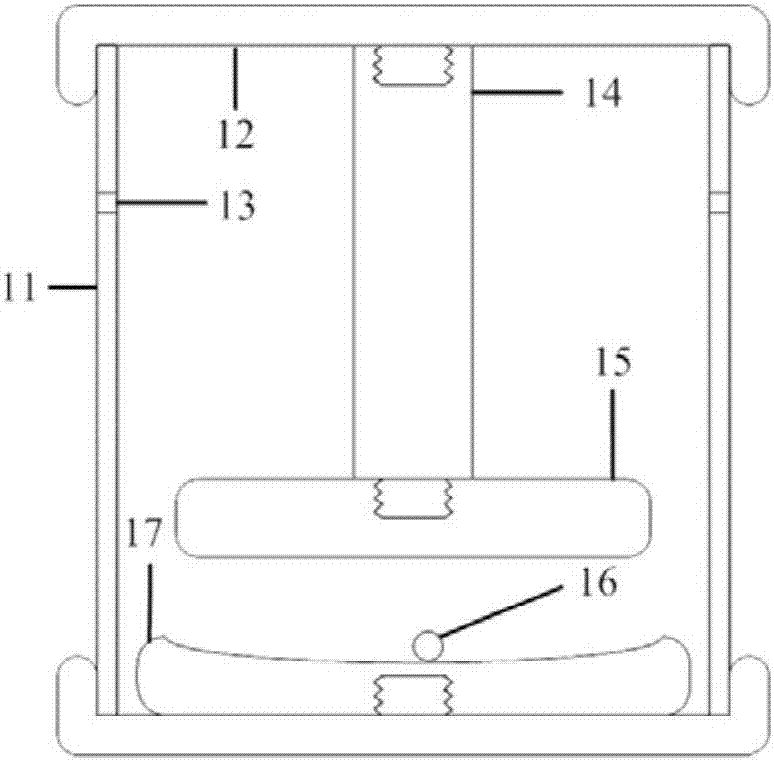

[0024] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com