Lean production plan implementation system and implementation method

A technology of production planning and lean production, applied in the field of bar codes, can solve the problems that suppliers cannot deliver goods in time, enterprises cannot produce normally, and enterprise production and manufacturing management has no practical guiding significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0227] The hardware condition of the embodiment of the present invention is as follows:

[0228] ISBN printer

[0229] barcode scanning device

[0230] Operating system installed on the barcode scanning device: Windows CE

[0231] Install one of the following operating systems on the PC:

[0232] Windows 2003

[0233] Windows 7

[0234] Windows Vista

[0235] Windows XP

[0236] Windows 2000

[0237] The PC where the software is to be installed has .net framework 2.0 installed

[0238] Administrator privileges on the PC where the software is to be installed

[0239] The database enables both local and remote connections using TCP / IP and named pipes (B)

[0240] An embodiment of the present invention provides a lean production planning implementation system implementation method, which includes the following steps:

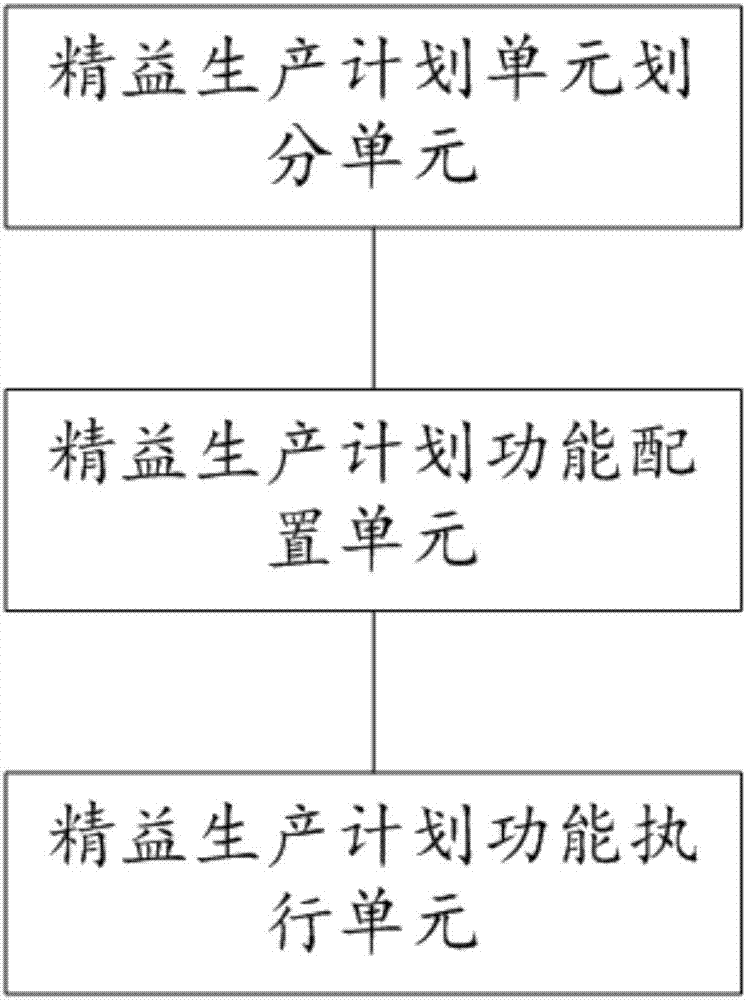

[0241] S1. Divide the lean production plan realization system into sales order management unit, delivery plan management unit, delivery plan detailed man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com