Manufacturing method of single-sided light-emitting csp light source

A single-sided light-emitting and manufacturing method technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the reliability, safety, shortening life of the light source, and reducing the brightness of the light source, so as to avoid lateral and bottom light emission. , Improve the light efficiency, and facilitate the effect of concentrating light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

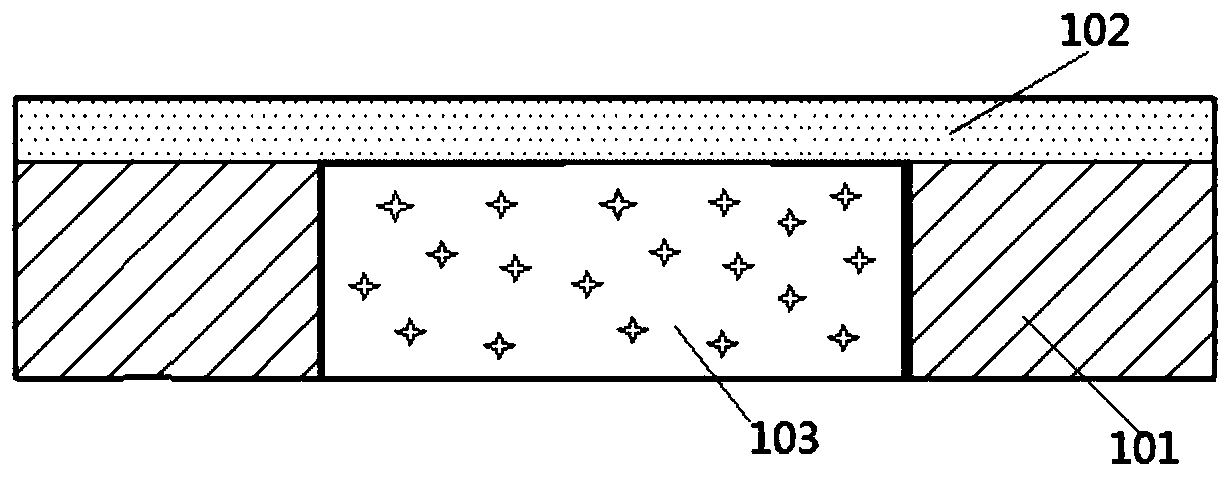

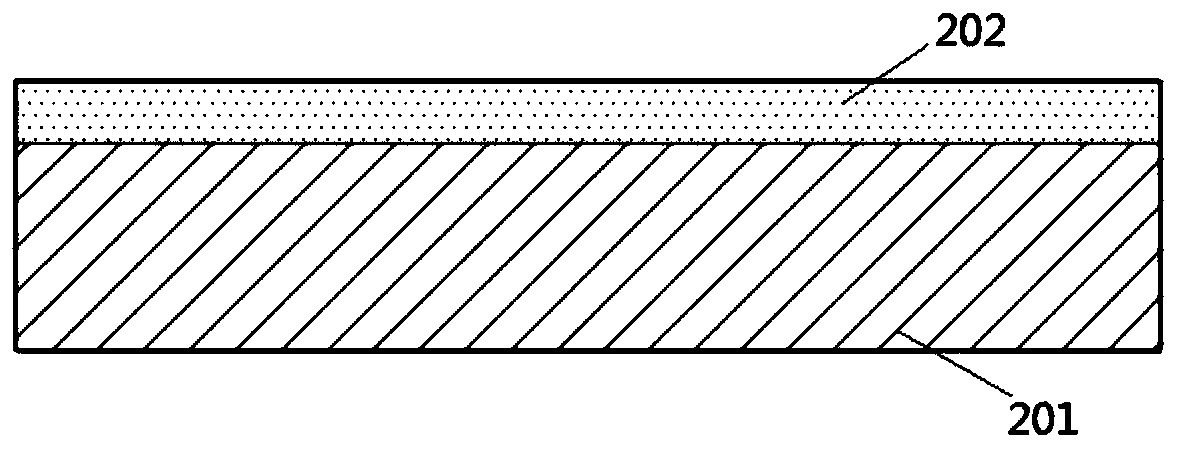

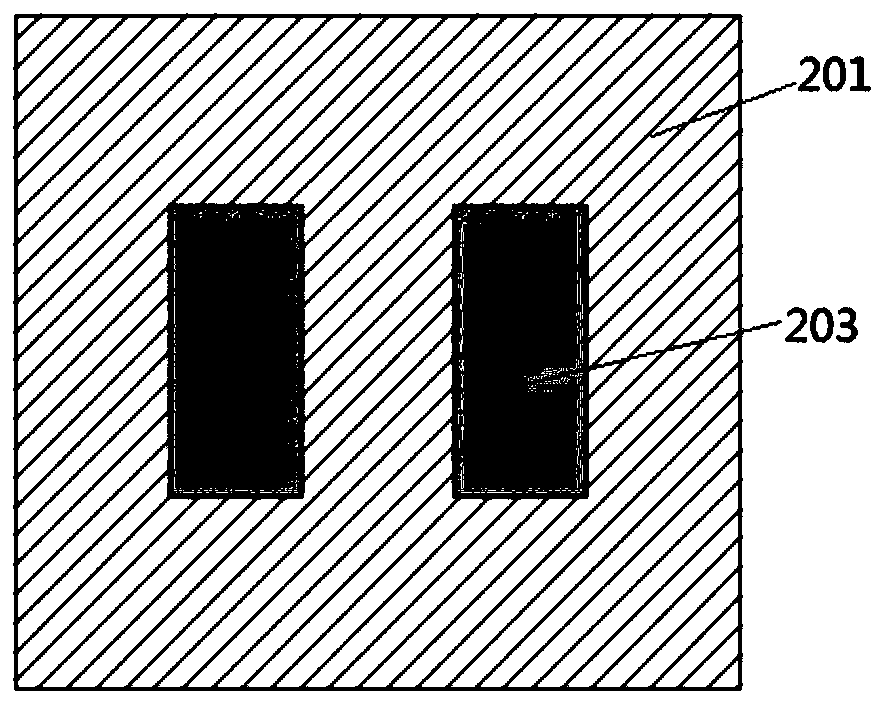

[0048] see Figure 2~4 , the single-sided light-emitting CSP light source of the present invention includes a light-emitting chip 204, a fluorescent adhesive layer 202, a transparent adhesive layer 205, and a white adhesive layer 201. The light-emitting chip 204 is located directly below the fluorescent adhesive layer 202, and the transparent adhesive layer 204 is set On the periphery of the light-emitting chip 204, adjacent to the periphery of the light-emitting chip 204 and connected to the upper fluorescent glue layer 202, the white glue layer 201 is located on the periphery of the light-transmitting glue layer 205 and connected to the upper fluorescent glue layer 202. The light-emitting chip 204, light-transmitting The upper surfaces of the adhesive layer 205 and the white adhesive layer 201 are all in contact with the lower surface of the fluorescent adhesive layer 202, so that the overall structure is compact and the light output effect is good, and the fluorescent adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com