A kind of EPDM rubber polyurethane composite acoustic packaging material and preparation method thereof

A technology of EPDM rubber and packaging materials, which is applied in the field of acoustic materials, can solve problems such as poor low-frequency sound absorption performance, and achieve the effects of improving low-frequency sound absorption characteristics, low cost, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

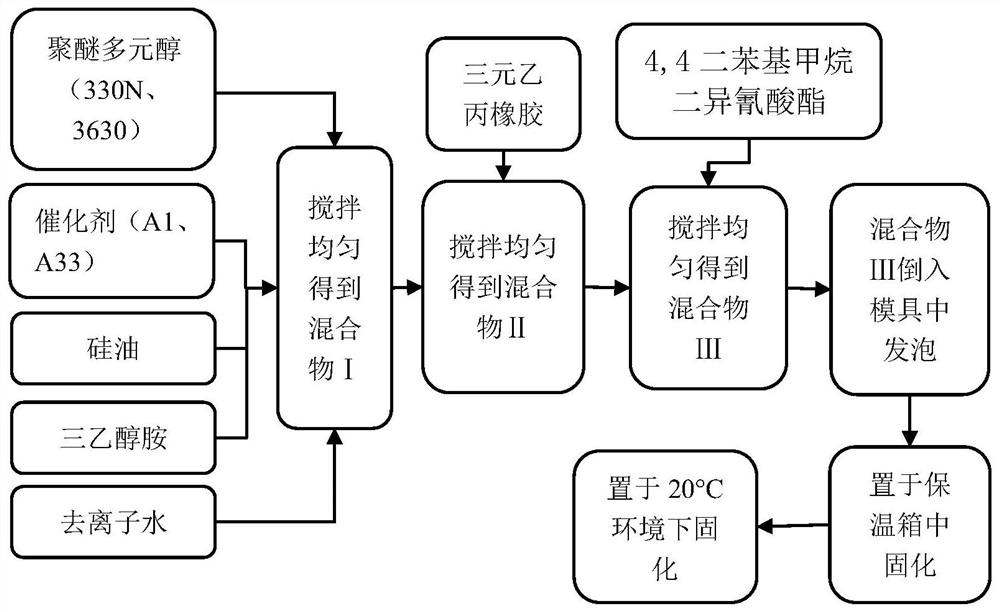

[0031] A preparation method of EPDM polyurethane composite acoustic packaging material, said method comprising the following steps:

[0032] refer to figure 1 , Step 1. Mix 60g of polyether polyol 330N, 40g of polyether polyol 3630, 3g of deionized water, 3g of triethanolamine, 0.05g of catalyst A1, 1g of catalyst A33 and 1.8g of silicone oil into a paper cup, at 25°C Stir with an electric stirrer at a speed of 2000rpm for 2 minutes to obtain mixture I;

[0033] Step 2. Add 2g or 4g or 6g or 8g of EPDM rubber with a hardness of 65HA or 4g of EPDM rubber with a hardness of 70HA or 4g of EPDM rubber with a hardness of 85HA into the mixture I obtained in step 1, and use it again Stir with an electric mixer for 2 minutes to obtain a homogeneous mixture II;

[0034] Step 3: Add 30 g of 4,4'-diphenylmethane diisocyanate to the mixture II obtained in step 2, and then use an electric stirrer to stir evenly to obtain mixture III;

[0035] Step 4. Pour the mixture III obtained in ste...

Embodiment 1

[0038] A kind of EPDM rubber polyurethane composite acoustic packaging material, said material is according to the following proportioning group:

[0039]

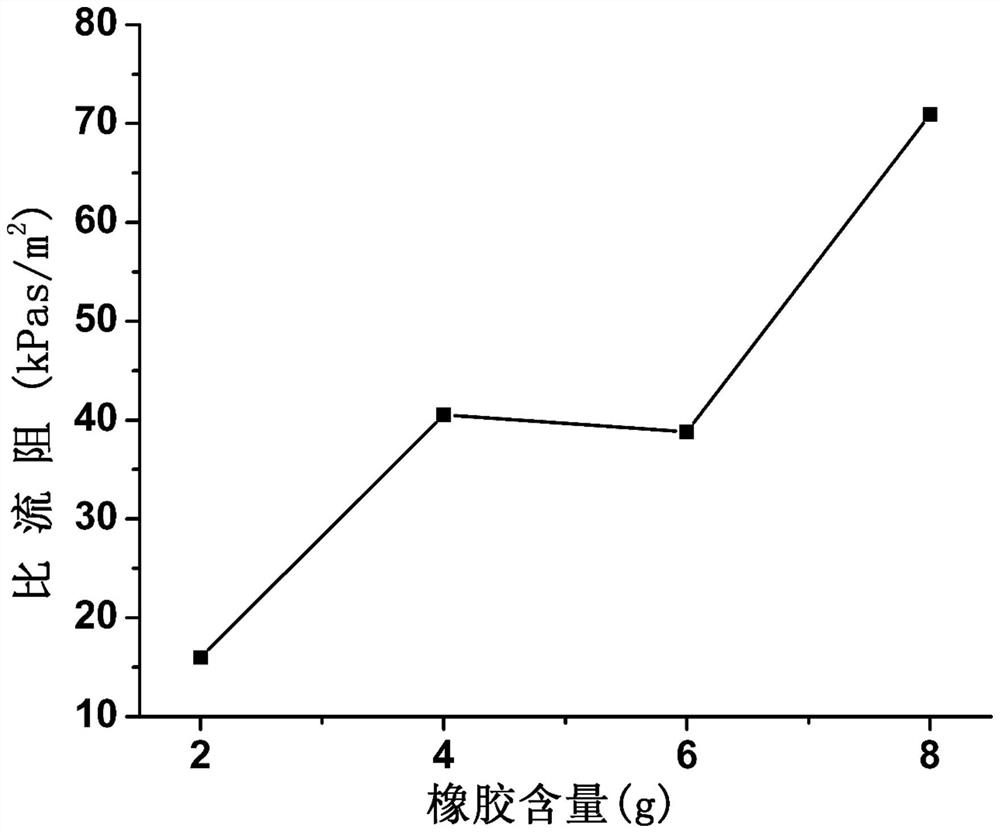

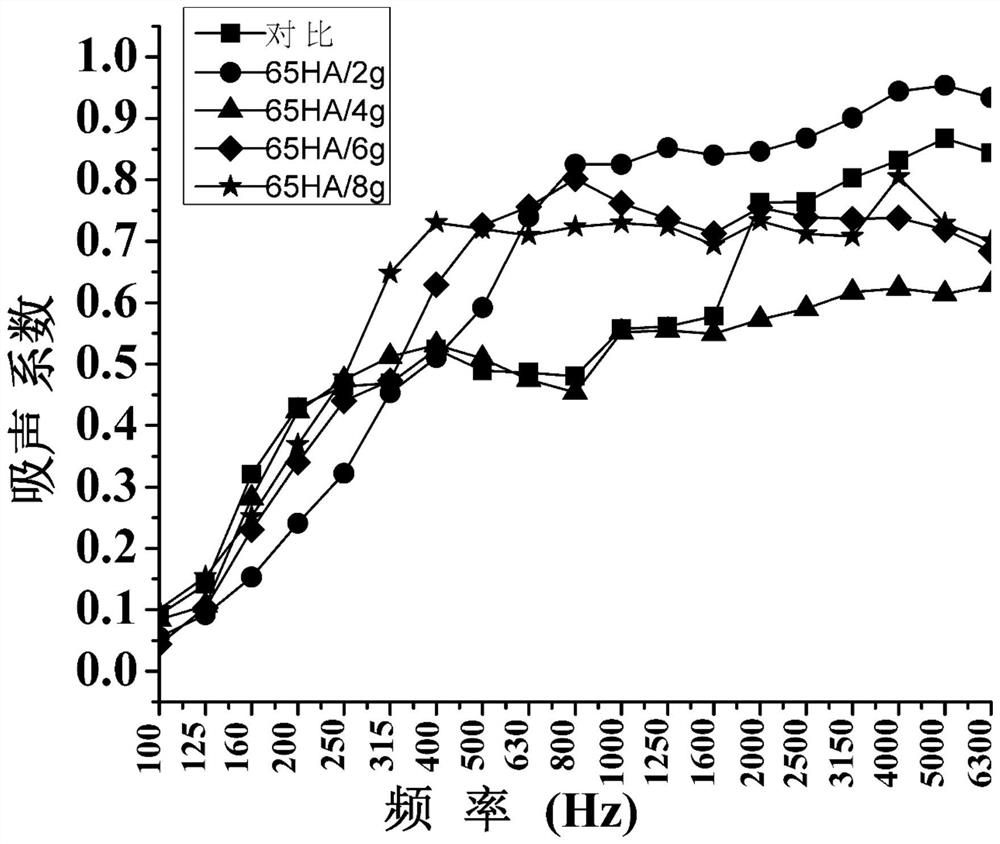

[0040] 2g or 4g or 6g or 8g of EPDM rubber with a hardness of 65HA.

[0041] A preparation method of EPDM polyurethane composite acoustic packaging material, said method comprising the following steps:

[0042] Step 1. Formula with exactly the same components and contents in 4 parts: 60g polyether polyol 330N, 40g polyether polyol 3630, 3g deionized water, 3g triethanolamine, 0.05g catalyst A1, 1g catalyst A33, 1.8g silicone oil Each part of the mixture was mixed separately and added to 4 identical paper cups, and stirred with an electric stirrer at 2000rpm for 2 minutes at 20°C to obtain 4 identical mixtures I;

[0043] Step 2. Add 2g, 4g, 6g, and 8g of EPDM rubber with a hardness of 65HA into the 4 paper cups in Step 1, and stir again with an electric stirrer to obtain 4 different mixtures II;

[0044] Step 3. Add 4...

Embodiment 2

[0050] A kind of EPDM rubber polyurethane composite acoustic packaging material, said material is according to the following proportioning group:

[0051]

[0052] 4g of EPDM rubber with a hardness of 65HA or 4g of EPDM rubber with a hardness of 70HA or 4g of EPDM rubber with a hardness of 85HA.

[0053] A preparation method of EPDM polyurethane composite acoustic packaging material, said method comprising the following steps:

[0054] Step 1, 3 parts of the formula with exactly the same components and contents: 60g polyether polyol 330N, 40g polyether polyol 3630, 3g deionized water, 3g triethanolamine, 0.05g catalyst A1, 1g catalyst A33, 1.8g medium Mix each portion of the mixture into 3 identical paper cups, and stir with an electric stirrer at 2000 rpm for 2 minutes at 20°C to obtain 3 identical mixtures I;

[0055] Step 2. Add 4 g of EPDM rubbers with different hardnesses of 65HA, 70HA and 85HA to the 3 mixtures I obtained in step 1, and stir again with an electric st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com