Replacing device of burner of annealing furnace

A technology of annealing furnace and guiding unit, which is applied in the direction of furnace, heat treatment furnace, furnace type, etc., and can solve the problems that the verticality between the burner and the furnace wall cannot be guaranteed, the refractory material and fiber seal of the burner are damaged, and the temperature of the annealing furnace is high. , to achieve the effect of saving manpower, improving operation quality and high labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

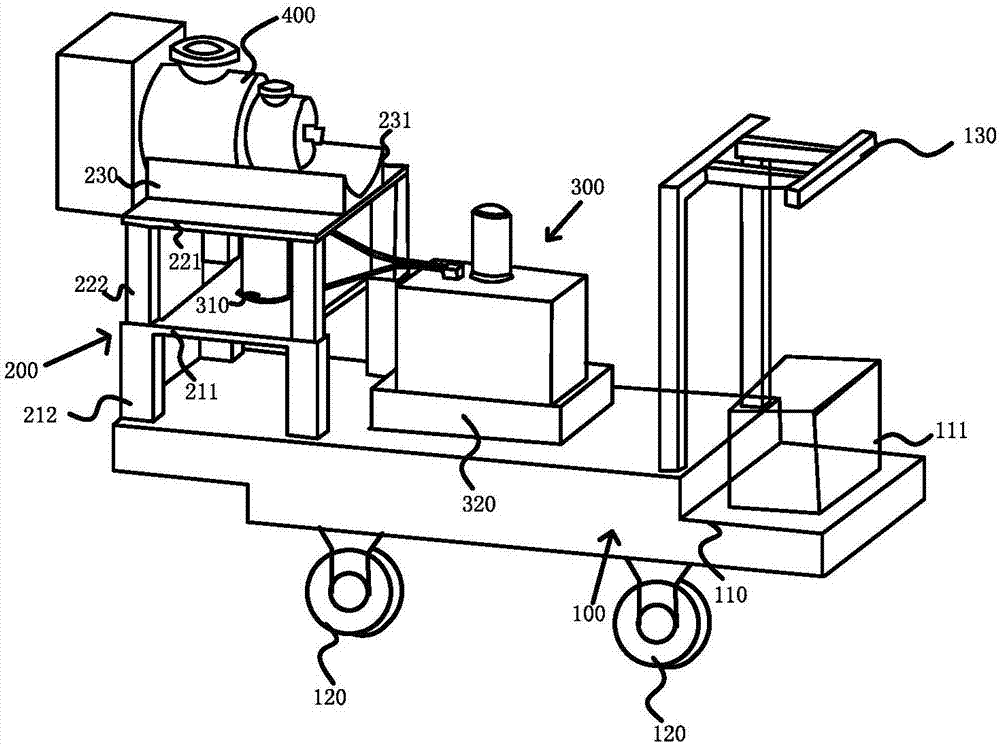

[0019] like figure 1 As shown, the annealing furnace burner replacement device includes a transport unit 100; a guide unit 200, which is arranged at one end of the transport unit 100, and the guide unit 200 is provided with a placement block 230, which is used to place the annealing furnace burner 400 ; Power unit 300, one end of which is set in the guide unit 200 for adjusting the height of the guide unit 200.

[0020] The transport unit 100 is used to transport the old annealing furnace burner 400 or the new annealing furnace burner 400 ; the guide unit 200 is used to carry the annealing furnace burner 400 ; the power unit 300 can provide power to adjust the height of the guide unit 200 .

[0021] The guide unit 200 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com