Barrel plating device and operation method thereof

A barrel plating and roller technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high cost, low efficiency, poor quality, etc., and achieve the effects of good stability, simple and fast operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

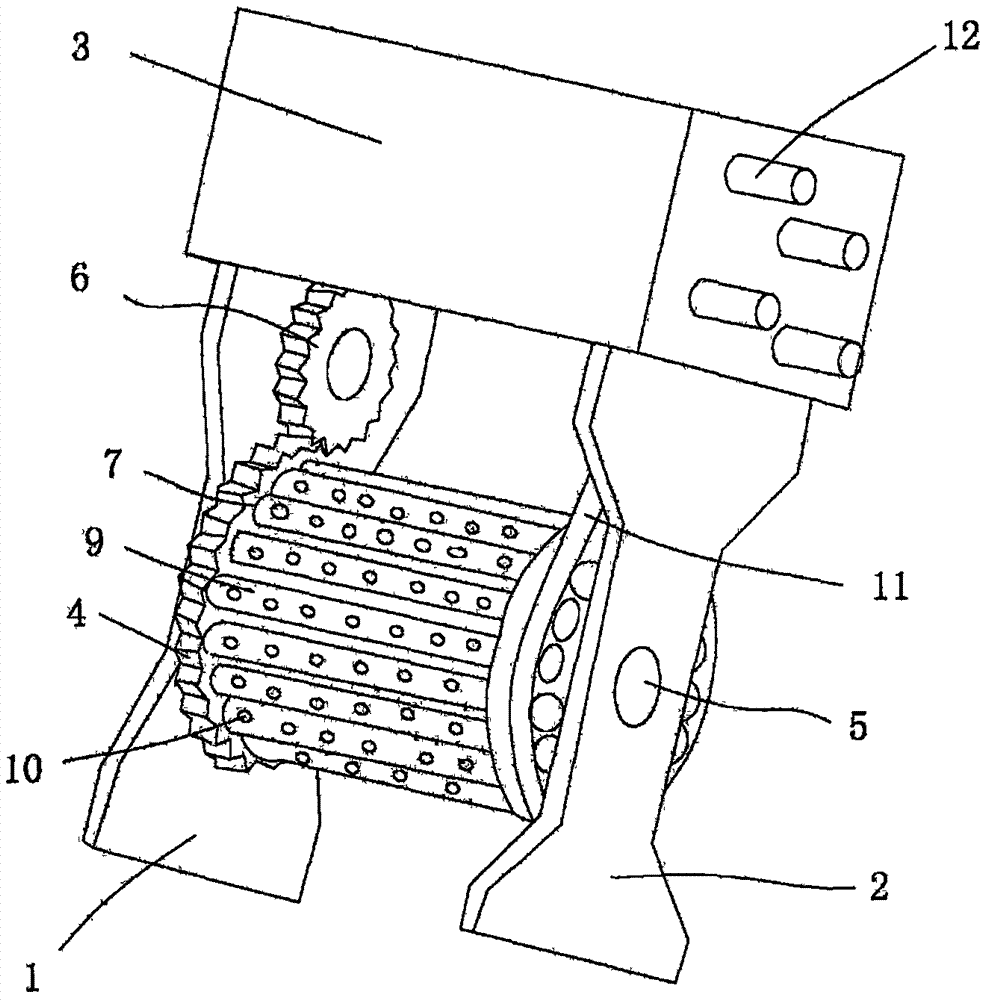

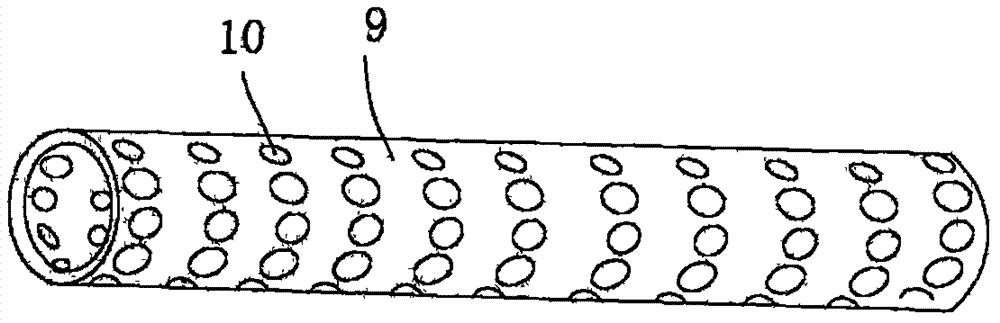

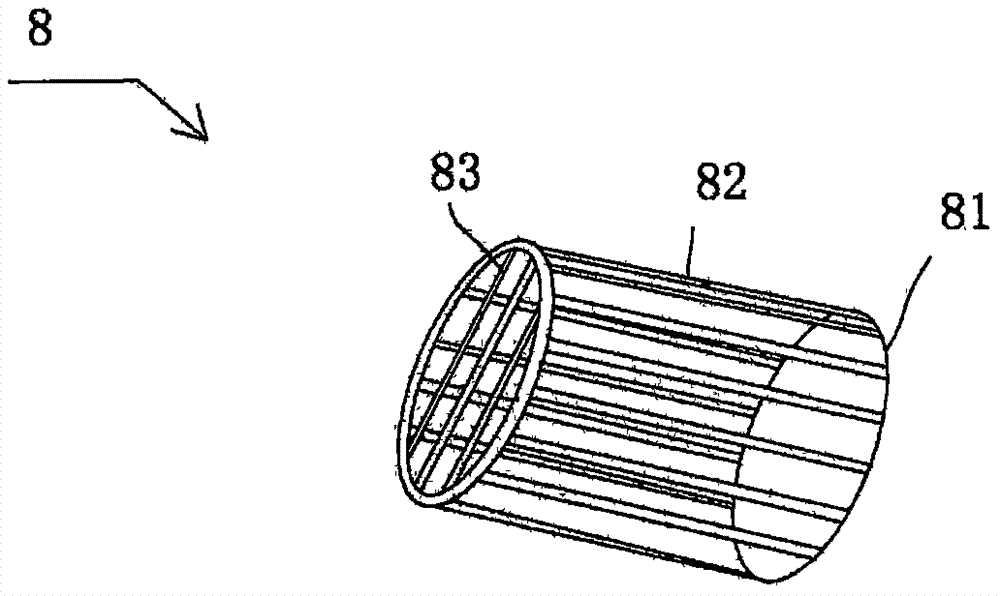

[0019] Figure 1 to Figure 3 A specific embodiment of the present invention is shown, wherein figure 1 Schematic diagram of the structure of the present invention; figure 2 Is a schematic diagram of the structure of the insulating tube of the present invention; image 3 Is a schematic diagram of the structure of the metal isolation cover of the present invention;

[0020] see Figure 1 to Figure 3 , A barrel plating device, the left support plate 1 and the right support plate 2, on the top of the left support plate 1 and the right support plate 2 is provided with a control box 3, on the left support plate 1 a roller sprocket 4 , The center of the roller gear plate 4 is connected to the middle of the left support plate 1 and the right support plate 2 through a rotating shaft 5. The roller gear plate is connected between the left support plate and the right support plate through the rotating shaft, which can facilitate the roller gear plate The rolling and connecting with the con...

Embodiment 2

[0031] Figure 4 A specific embodiment of the present invention is shown, wherein Figure 4 It is a flowchart of the operation method of the present invention.

[0032] A method for operating a barrel plating device includes the following steps:

[0033] Step A: Place the parts in the metal isolation cover. The parts in the metal isolation cover are always in reliable contact with the metal isolation cover under the action of gravity, and the metal isolation covers are pressed against each other through the plug or cover of the insulating tube to realize the metal isolation cover mutual At the same time, the metal isolation cover is reliably connected with the conductive ring in the drum gear plate, and the conductive ring is connected with the cathode wire of the power supply through the conductive metal shrapnel, so as to achieve reliable electrical conduction of all parts;

[0034] Step B: Start the drive motor, and drive the roller gear plate to rotate through the drive gear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com