Target boundary extraction method based on laser stripe geometric feature mutation

A geometric feature and boundary extraction technology, applied in the field of visual measurement, which can solve problems such as misalignment, different levels and widths of light bar grayscale distribution, disconnection and discontinuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be described in detail below in conjunction with technical methods and accompanying drawings.

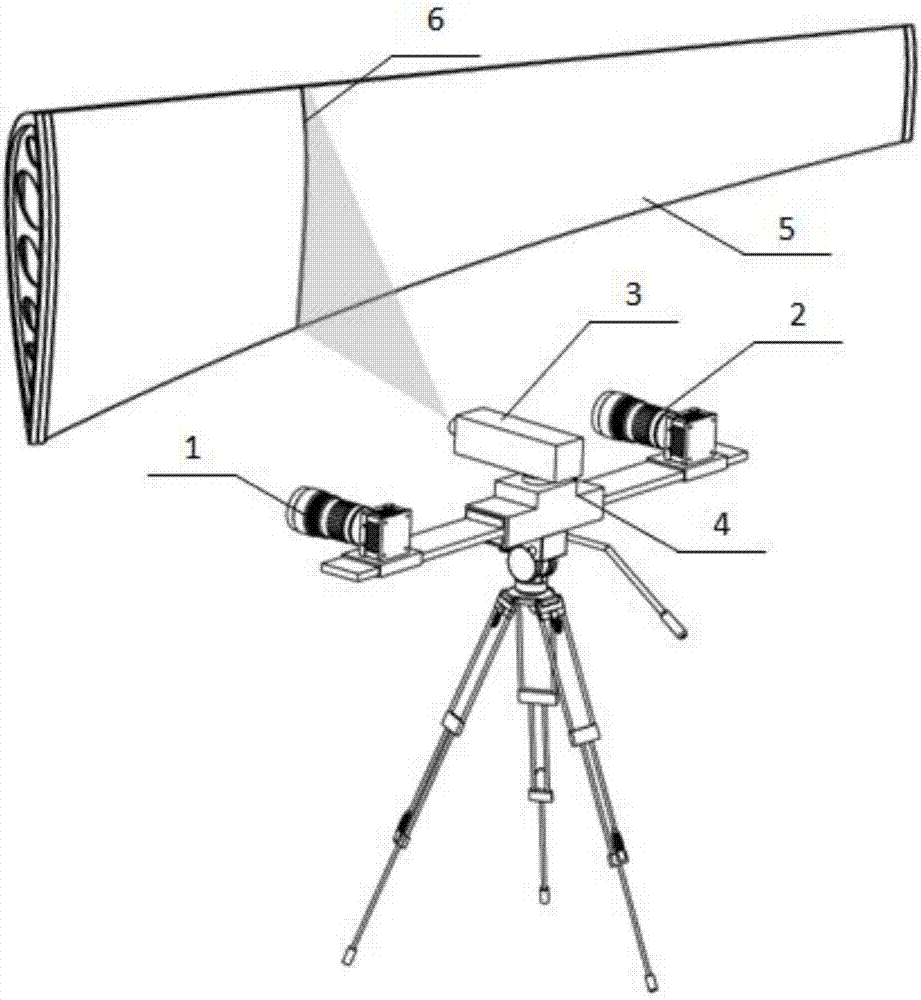

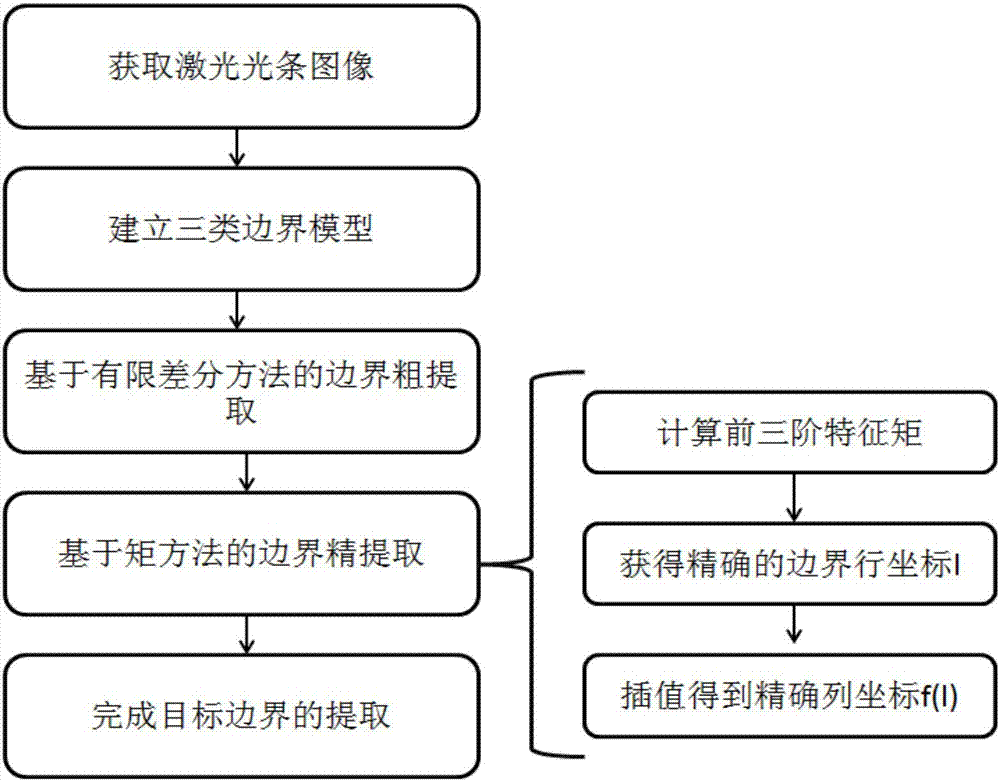

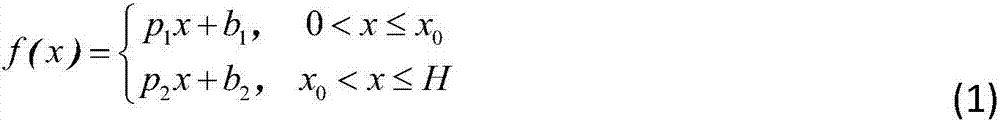

[0052] First, by combining laser with binocular vision, the left and right cameras 1 and 2 are used to shoot the auxiliary laser stripes 6 formed by the laser emitter 3 on the measured object 5 to obtain the image of the laser stripes 6; secondly, according to the main In the case of existing boundary light strips, establish three types of boundary models; then, use the differential operation to derive the boundary feature vector h to obtain the coordinates of the roughly extracted target boundary feature points; finally, according to the principle of moment invariance, obtain the finely extracted target boundary Feature point coordinates; the specific steps of the method are as follows:

[0053] The first step is to obtain point cloud data

[0054] This measurement selects the VC‐12MC‐M / C 65 industrial camera produced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com