Special smashing machine for sewage discharge

A sewage discharge and grinder technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as clogged sewage pipes, and achieve strong shearing force and twisting Good crushing effect and reasonable system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

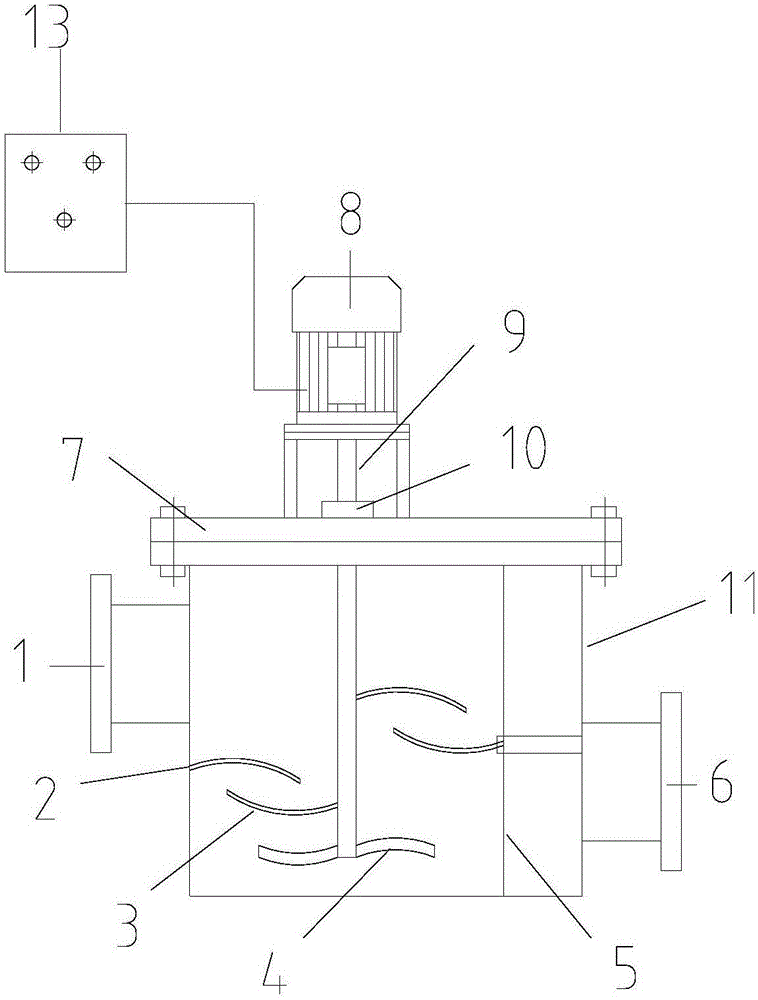

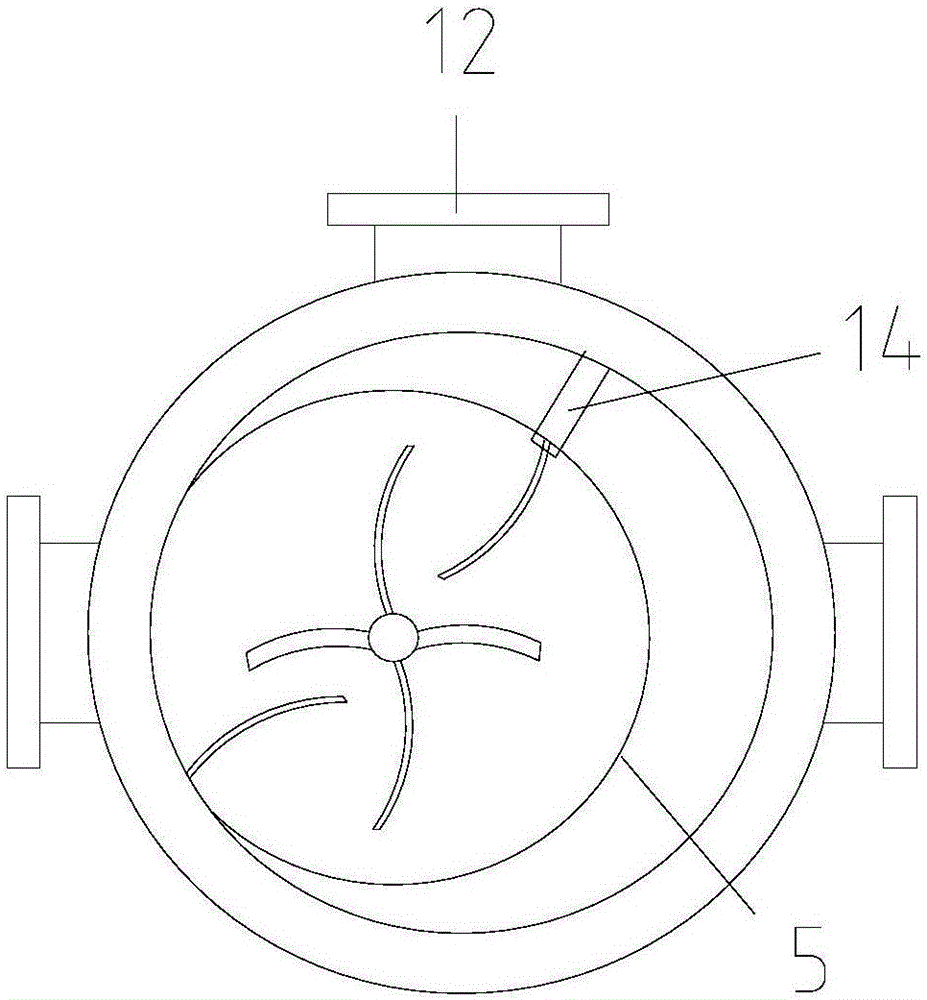

[0026] This embodiment discloses a special grinder for sewage discharge, including a motor 8, an electric control box 13, a cylinder body 11, a shaft seat 10, a rotating shaft 9, a passive reamer 2, a passive reamer base 14, an active reamer 3, Scraper 4, circular filter cartridge 5, cover plate 7, water inlet 1, water outlet 6, side outlet 12; the water inlet 1 is located at the upper left side of the cylinder 11; the water outlet 6 is located at the The lower part of the right side of the cylinder body 11; the side flow port 12 is located behind the cylinder body 11; the cover plate 7 is located at the upper part of the cylinder body 11; the shaft seat 10 is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com