Pressure control device of large precise ring hot rolling pressure ring rolling machine

A pressure control, ring rolling technology, applied in tension/pressure control, workpiece cooling device, metal rolling, etc., can solve the problems of ring extrusion deformation, inability to record the position and size of the die, unstable product quality, etc. The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

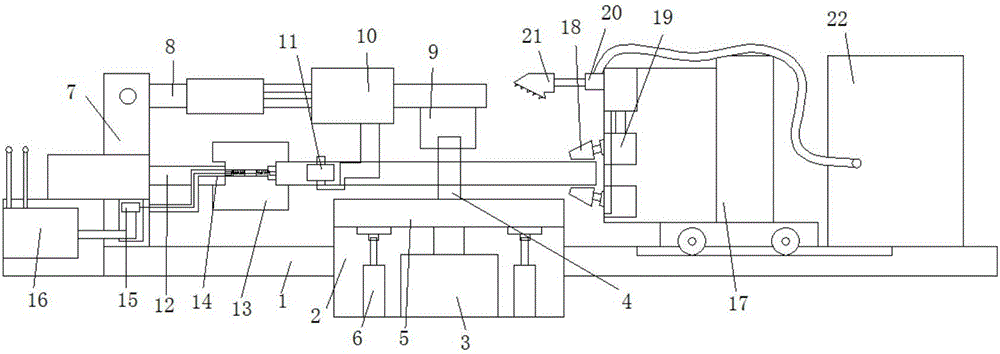

[0010] Referring to the accompanying drawings, a pressure control device for a large-scale precision ring hot-rolled pressure ring mill includes a bottom plate 1, a cavity 2 is provided in the middle section of the bottom plate 1, and a fixing seat 3 is fixedly installed in the cavity 2, The top of the fixed seat 3 is provided with a guide rod 4, the top of the guide rod 4 is provided with a support platform 5, and the lower surface of the support platform 5 is provided with a lifting cylinder 6 that can control the lifting of the support platform 5, and the base plate 1 A column 7 is provided at the left end of the column, and a beam 8 is hinged on the column 7. The end of the beam 8 is provided with a fixed sleeve 9, and the fixed sleeve 9 is interlocked with the guide rod 4. The beam 8 is provided with A slider 10, the lower surface of the slider 10 is provided with a squeeze roller 11, the slider 10 can slide left and right on the beam 8 through the control of the cylinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com