Reactor core shroud assembly welding clamping device and clamping and welding method

A clamping device and reactor technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficulty, repeated clamping, useless power, etc., to simplify the operation difficulty, improve the production efficiency, and improve the success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation of the reactor core shroud assembly welding and clamping device and the clamping and welding method of the present invention will be described in detail below in conjunction with the accompanying drawings.

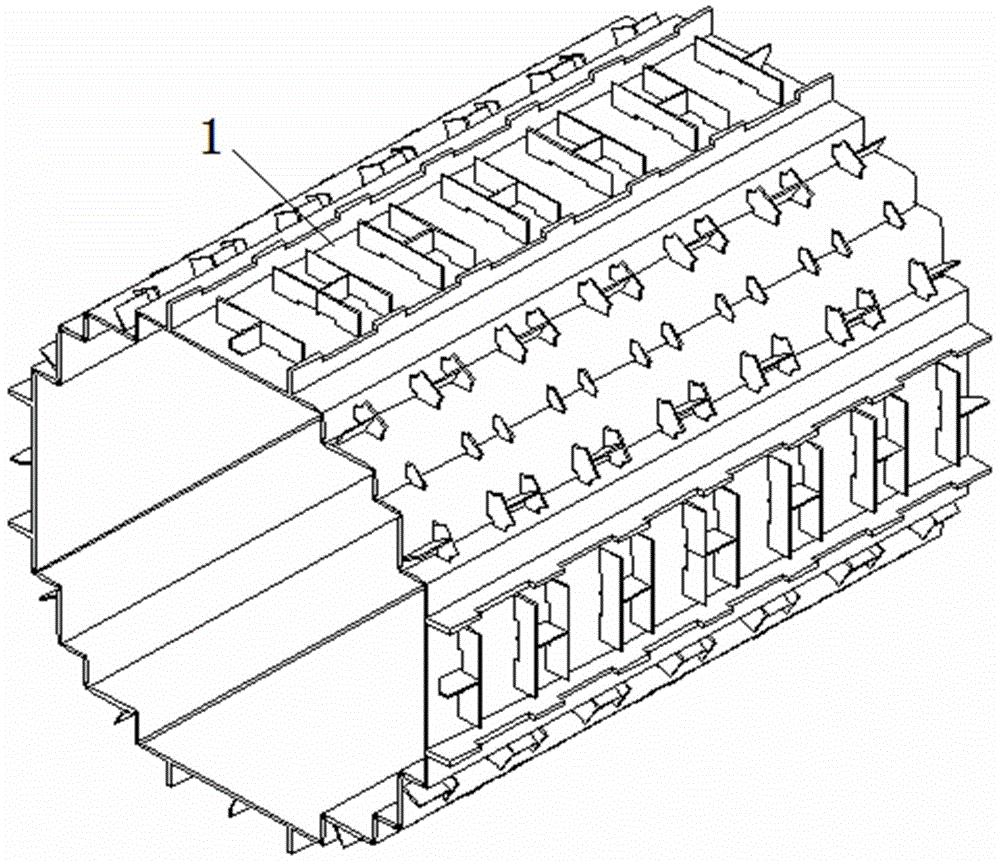

[0049] See attached figure 1 , the reactor core shroud 1 is a cylindrical structure, composed of multiple sub-assemblies, a plurality of stepped joint surfaces are formed on the cylinder body, and the stepped joint surfaces are perpendicular to each other, forming 8 joint seams on the cylinder body, processed The process requires laser welding of 8 seams to form the overall structure of the core shroud 1 .

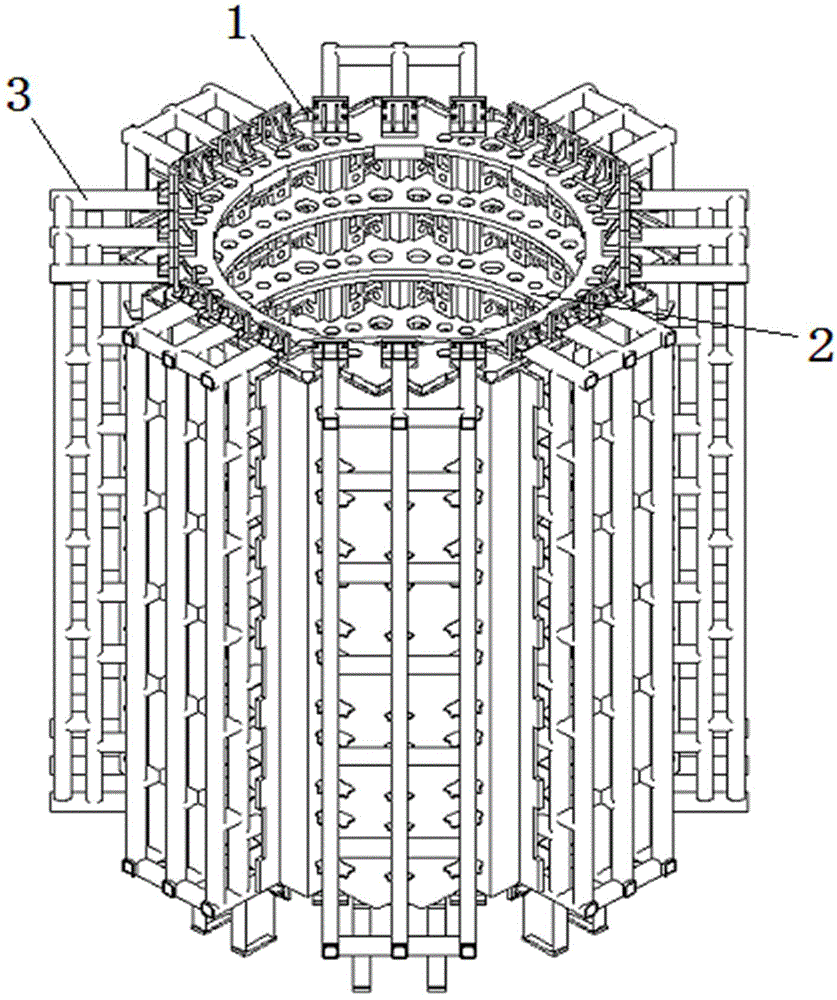

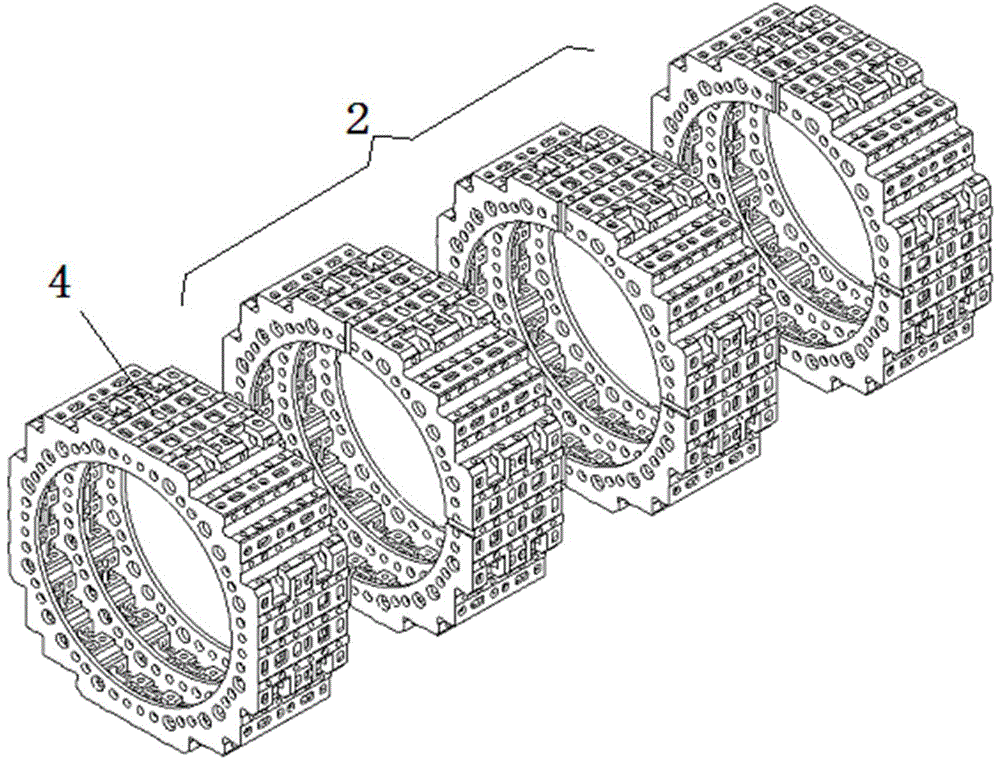

[0050] The welding process will be carried out on the clamping device, see attached figure 2 , the clamping device mainly includes an inner support assembly 2, an outer hoop assembly 3 and a roller assembly, the inner support assembly 2 is arranged inside the core shroud 1, and the outer hoop assembly 3 is arranged outside the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com