Manual wrench facilitating unscrewing or screwing of nut in narrow space

A space and nut technology, applied in the field of manual wrenches, can solve the problems of long and narrow space, troublesome and laborious work in removing or tightening nuts, and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

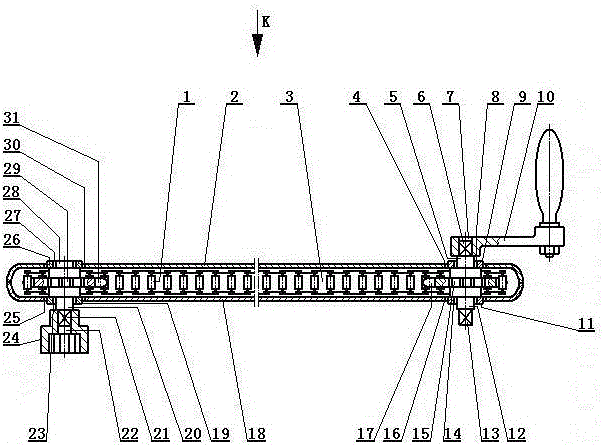

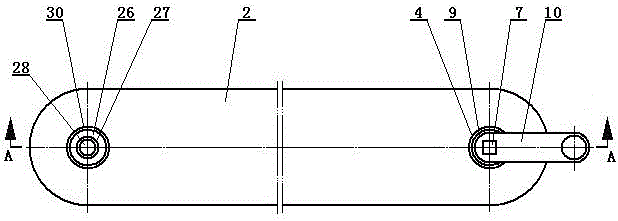

[0019] Embodiment: As shown in the accompanying drawings, it consists of a chain 1, an upper casing 2, a first bushing 9, a hand crank 10, a second bushing 11, a driving sprocket 15, a lower casing 18, and a third bushing 19 , the sleeve 24, the fourth bushing 26 and the driven sprocket 29 constitute a manual wrench that is convenient for removing or tightening nuts in a long and narrow space. The right end of empty 3 is provided with driving sprocket 15, and the left end of inner space 3 is provided with driven sprocket 29, and the gear tooth A17 of driving sprocket 15 and the right end engagement transmission of chain 1, the left end of chain 1 and driven sprocket 29 The gear teeth B31 mesh transmission.

[0020] The first journal 5 of the integral structure at the upper end of the driving sprocket 15 is in dynamic fit with the central hole A8 of the first bushing 9, and the lower end of the outer diameter of the first bushing 9 is inserted into the first through hole 4 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com