Grass silk fiber and method for preparing simulation lawn

A technology of fiber and grass, applied in the field of outdoor sports equipment, can solve the problems of single structure of simulated lawn and performance that cannot meet the needs of diversified use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

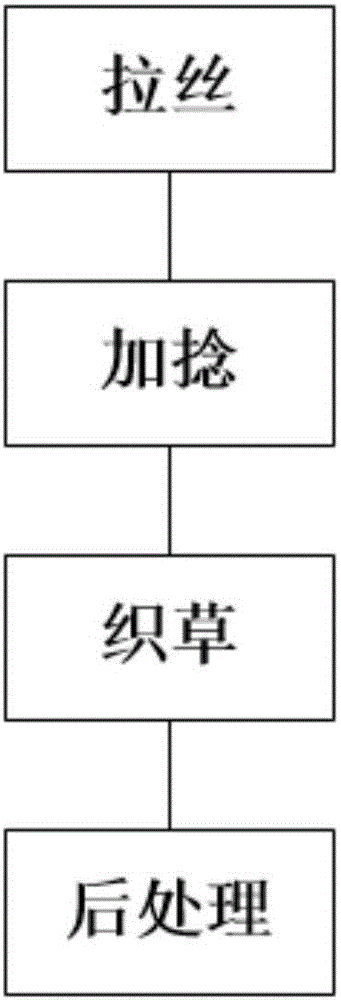

Method used

Image

Examples

Embodiment 1

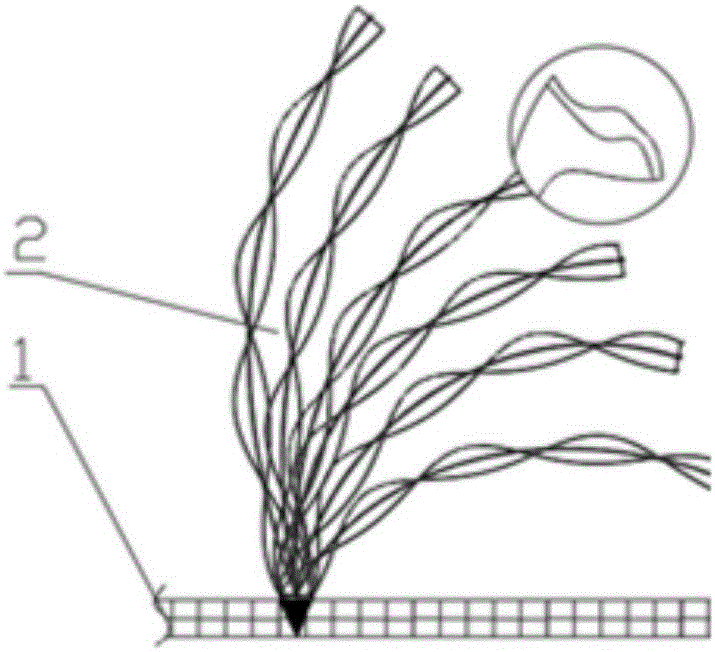

[0033] Weigh 850g of linear low density polyethylene, 150g of high density polyethylene, 100g of functional elastic material, 40g of color masterbatch, 10g of smooth masterbatch, 10g of nucleating agent and 8g of PPA. Extrusion and stretching steps; then, under the condition of 110° C., after secondary stretching and setting by hot air setting method, the grass fiber 1 with a score of 650 is wound. In this embodiment, the selected functional elastic material is TPE. The prepared grass fiber 1 has a three-dimensional helical structure by using the method of secondary stretching and setting.

[0034] After the grass fiber 1 is twisted, the grass weaving step is carried out, and the grass fiber 1 is woven on the surface of the grass weaving base cloth 1 to obtain an intermediate product 1 . Wherein, the weaving grass base cloth 1 is made up of 2 layers of anti-aging base cloth 1 and 1 layer of air variable gauze cloth 1 arranged on the upper surface of the anti-aging base cloth ...

Embodiment 2

[0038] Weigh 900g of linear low density polyethylene, 50g of high density polyethylene, 150g of functional elastic material, 60g of color masterbatch, 20g of smooth masterbatch, 20g of nucleating agent and 10g of PPA. Extrusion and stretching steps; then, under the condition of 140° C., after secondary stretching and setting by hot air setting method, the grass fiber 2 with a score of 1666 is wound. In this embodiment, the selected functional elastic material is a mixture of TPO, TPV and POE. The prepared grass fiber 2 has a three-dimensional helical structure by using the method of secondary stretching and setting.

[0039] After the grass fiber 2 is twisted, the grass weaving step is carried out, and the grass fiber 2 is woven on the surface of the grass weaving base cloth 2 to obtain an intermediate product 2. Wherein, grass weaving base cloth 2 is made up of 1 layer of anti-aging base cloth 2 and 1 layer of air variable gauze cloth 2 arranged on the upper surface of anti-...

Embodiment 3

[0043] Weigh 1000g of linear low density polyethylene, 100g of high density polyethylene, 50g of functional elastic material, 100g of color masterbatch, 15g of smooth masterbatch, 15g of nucleating agent and 7g of PPA. Extrusion and stretching steps; then, under the condition of 40° C., after secondary stretching and setting by hot air setting method, the grass fiber 3 with a Tex of 2000 is wound up. In this embodiment, the selected functional elastic material is a mixture of TPU, TPR and TPEE. Utilizing the method of secondary stretching and shaping, the prepared grass fiber 3 has a three-dimensional helical structure.

[0044] After the grass fiber 3 is twisted, the grass weaving step is carried out to weave the grass fiber 3 on the surface of the grass weaving base cloth 3 to obtain an intermediate product 3 . Wherein, the weaving grass base cloth 3 is made up of 3 layers of anti-aging base cloth 3 and 1 layer of air variable gauze cloth 3 arranged on the upper surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com