Method for modifying color of cambrayon dyed with active dye by using cationic dye

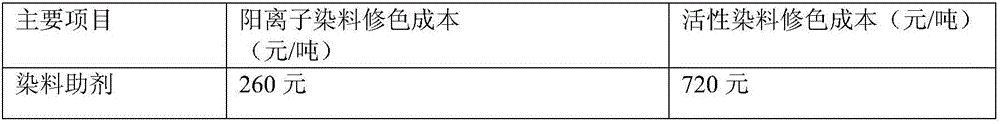

A technology of cationic dyes and reactive dyes, which is applied to the field of color retouching with cationic dyes after dyeing cotton grey fabrics with reactive dyes, can solve the problems of low utilization rate of dyes, increase of hydrolyzed reactive dyes, adverse environmental effects, etc., so as to eliminate the use of anionic auxiliaries. , Improve the stability and solubility, and avoid the effect of dye precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

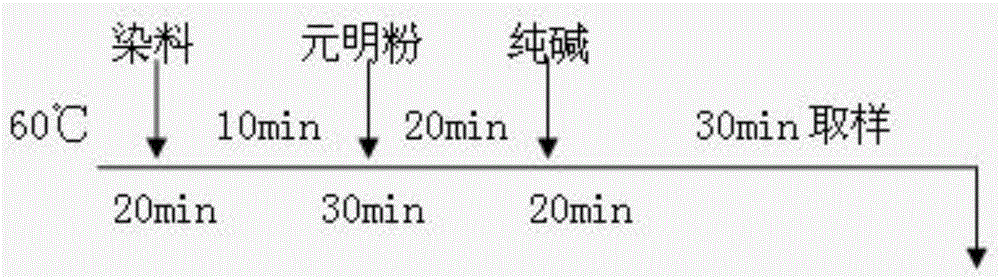

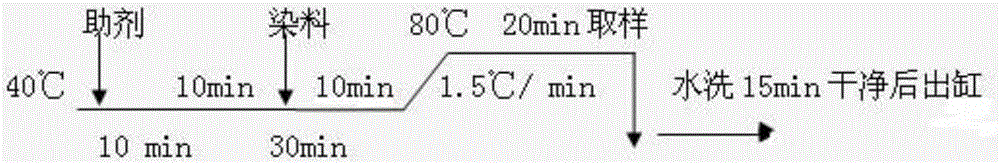

[0043] A kind of method for color repairing with cationic dye after reactive dye dyeing of cotton gray cloth, its process step is as follows:

[0044] 1) After the cotton gray cloth is dyed with reactive dyes, it is found that the shade does not match, and the repair gray cloth is first made with cationic dyes, and then the color is repaired in the air-flow dyeing machine;

[0045] 2) After the gray cloth to be repaired is put into the vat, the bath ratio is 1:5, the temperature is raised to 75°C at 4°C per minute and operated for 25 minutes, then the temperature is lowered to 60°C at 2°C per minute, washed with water at 50°C for 12 minutes, and the water is changed once;

[0046] 3) Bath ratio 1:4, heat up to 35°C at 4°C per minute, keep warm for 10 minutes, add glacial acetic acid, DS1230 non-ionic penetrant and sodium sulfate at the same time, run for 10 minutes after adding, and measure the pH value of the dyeing solution at 4- between 5;

[0047] 4) Melt the cationic dye...

Embodiment 2

[0053] A kind of method for color repairing with cationic dye after reactive dye dyeing of cotton gray cloth, its process step is as follows:

[0054] 1) After the cotton gray cloth is dyed with reactive dyes, it is found that the shade does not match, and the repair gray cloth is first made with cationic dyes, and then the color is repaired in the air-flow dyeing machine;

[0055] 2) After the gray cloth to be repaired is put into the vat, the bath ratio is 1:4, the temperature is raised to 80°C at 4.5°C per minute and operated for 20 minutes, and then the temperature is lowered to 60°C at 2.5°C per minute, washed with water at 50°C for 10 minutes, and the water is changed once;

[0056] 3) Bath ratio 1:4, heat up to 40°C at 4°C per minute, keep warm for 10 minutes, add glacial acetic acid, DS1230 non-ionic penetrant and sodium sulfate at the same time, run for 10 minutes after adding, and measure the pH value of the dyeing solution at 4- between 5;

[0057] 4) Melt the cati...

Embodiment 3

[0063] A kind of method for color repairing with cationic dye after reactive dye dyeing of cotton gray cloth, its process step is as follows:

[0064] 1) After the cotton gray cloth is dyed with reactive dyes, it is found that the shade does not match, and the repair gray cloth is first made with cationic dyes, and then the color is repaired in the air-flow dyeing machine;

[0065] 2) After the gray cloth to be repaired is put into the vat, the bath ratio is 1:6, the temperature is raised to 85°C at 5°C per minute and operated for 30 minutes, then the temperature is lowered to 60°C at 2°C per minute, washed with water at 50°C for 15 minutes, and the water is changed once;

[0066] 3) Bath ratio 1:4, heat up to 45°C at 4°C per minute, keep warm for 10 minutes, add glacial acetic acid, DS1230 non-ionic penetrant and sodium sulfate at the same time, run for 10 minutes after adding, and measure the pH value of the dyeing solution at 4- between 5;

[0067] 4) Melt the cationic dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com