Combined type double-vortex-tube turbine shell

A turbine casing and double scroll technology, applied in stators, engine components, machines/engines, etc., can solve the problems of difficult processing, high maintenance costs, complex structure, etc., achieve simple structure, improve adaptability, avoid The effect of complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

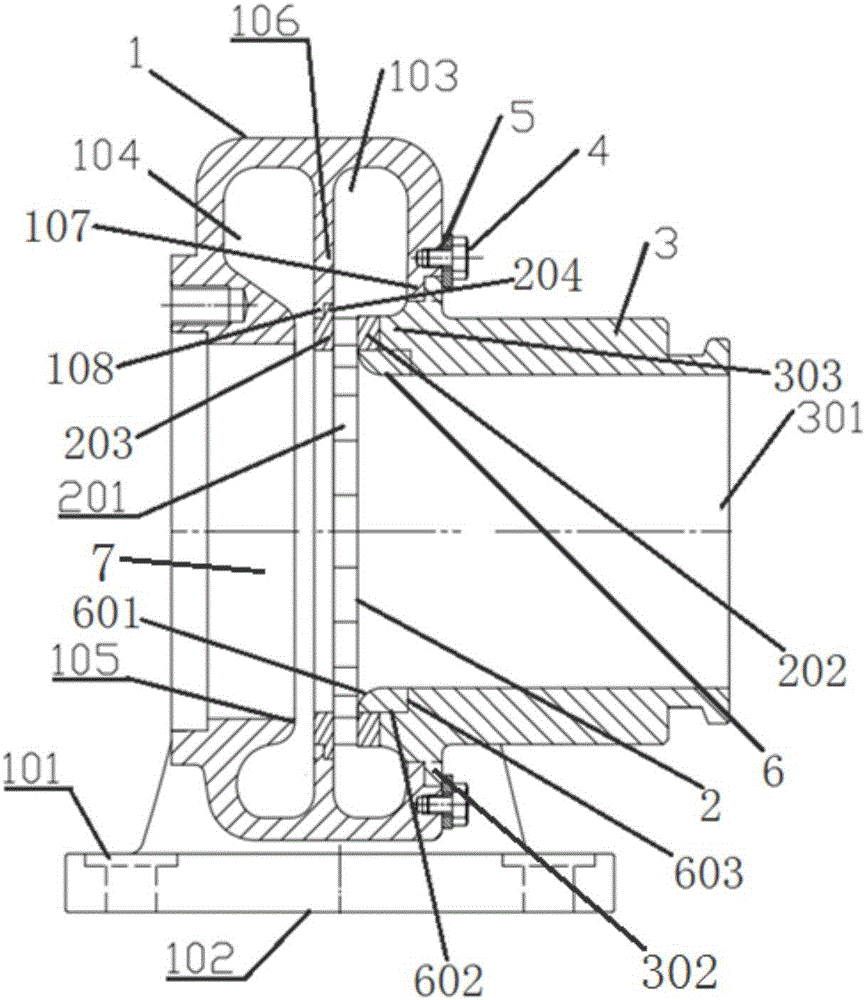

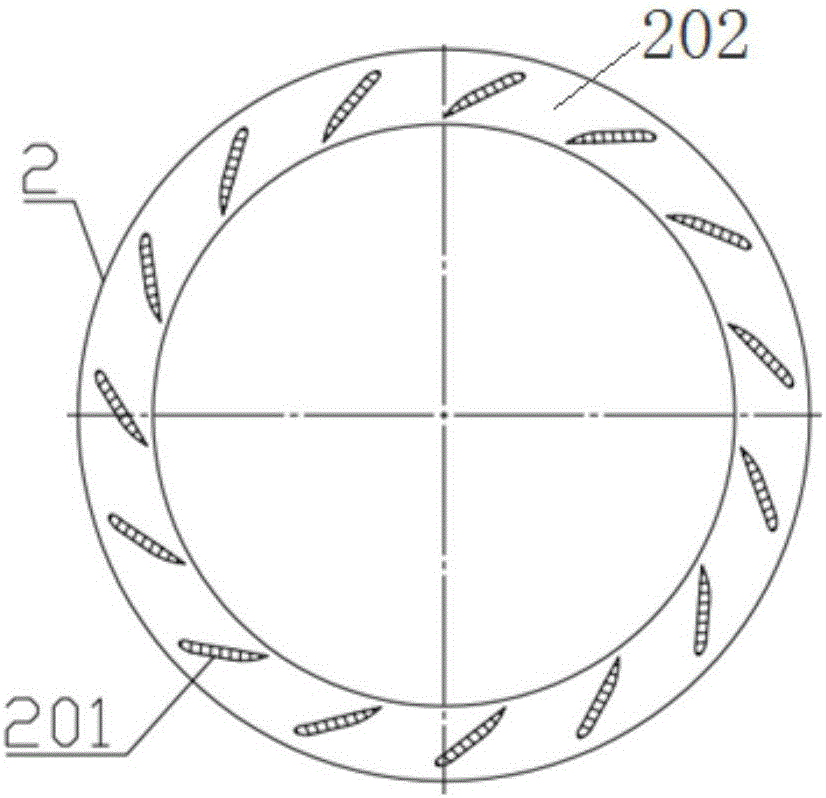

[0029] Such as figure 1 Shown is a combined double-scroll turbine casing, which includes a turbine casing main body 1 and an exhaust casing 3 connected to the turbine casing main body 1, and an exhaust port is opened at one end of the exhaust casing 3 301, an exhaust gas inlet 102 is opened on the main body 1 of the turbine housing, and a double-scroll mechanism and a turbine chamber 7 are sequentially arranged inside from the outside to the inside. 1. The second scroll channel 104, the first scroll channel 103 is located between the second scroll channel 104 and the exhaust casing 3, the exhaust gas inlet 102 passes through the first scroll channel 103, the second scroll channel The flow passage 104 communicates with the turbine chamber 7, the vane nozzle ring 2 is arranged between the first scroll passage 103 and the turbine chamber 7, and the vaneless nozzle 105 is arranged between the second scroll passage 104 and the turbine chamber 7 . A mounting flange 101 is provided...

Embodiment 2

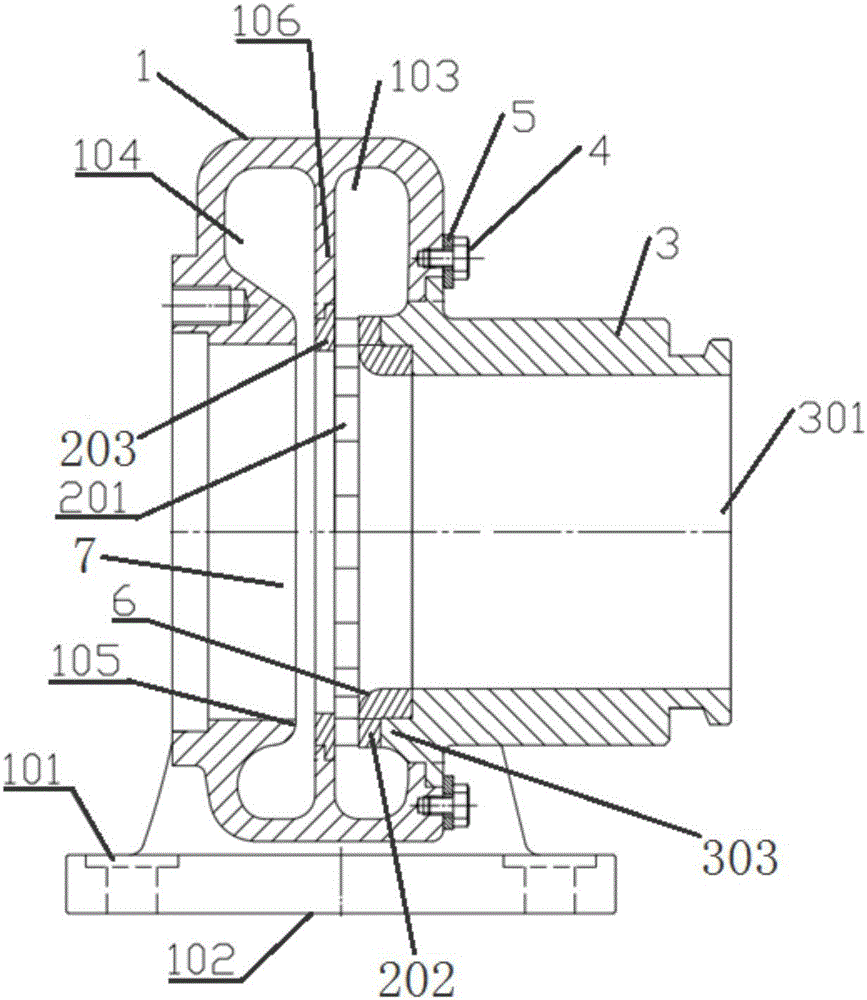

[0036] Such as image 3 As shown, in this embodiment, the transition ring 6 and the first guide vane fixing ring 202 are integrally structured, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com