Gas stove capable of adjusting pot holder automatically and control method of such gas stove

A technology of automatic adjustment and control method, applied in household stoves, heating fuels, heating methods, etc., can solve the problems of poor control accuracy, too simple structure, difficult to establish the corresponding relationship between pressure and flame height, etc., to achieve adjustment accuracy High, easy-to-implement, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

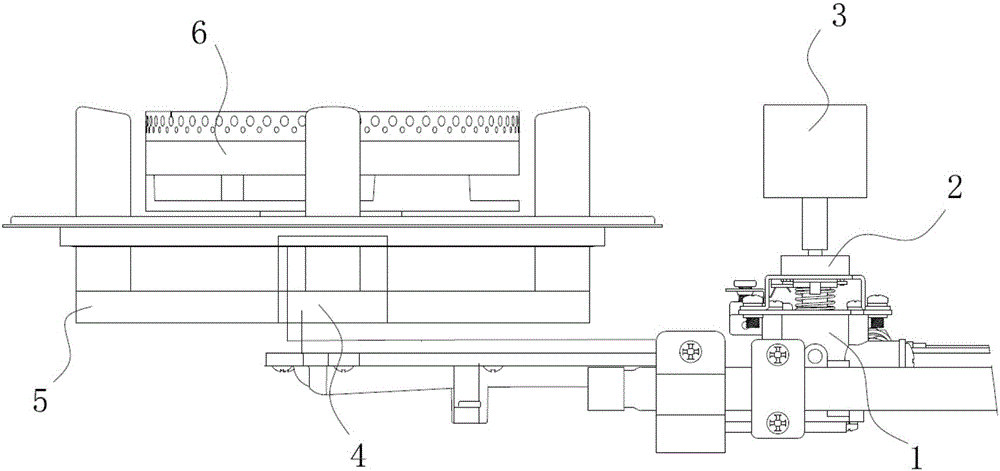

[0027] This embodiment provides a gas stove that automatically adjusts the pan support. Such as figure 1 As shown, the gas stove for automatically adjusting the pot support includes a valve body 1, on which a valve opening sensing module 2 and a knob 3 for adjusting the opening of the valve body 1 are arranged; the signal of the valve opening sensing module 2 is connected to the adjustment module 4. The adjustment module 4 can adjust the height of the pot support 5 according to the signal of the opening value of the valve body 1 detected by the valve opening sensing module 2 .

[0028] Wherein, the concrete mode that regulating module 4 regulates pot support 5 heights is not limited, can be regulating module 4 (inside is provided with the control devices such as single-chip microcomputer) according to open valve sensing module 2 signals to drive motor and send forward rotation or reverse order, drive According to the instruction, the motor controls the rotation of a threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com