A pressure-resistant flame-retardant optical cable

An optical cable and elastic layer technology, applied in the field of compression-resistant and flame-retardant optical cables, can solve the problems of easy extrusion damage, damage to human health, interruption of signal transmission, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

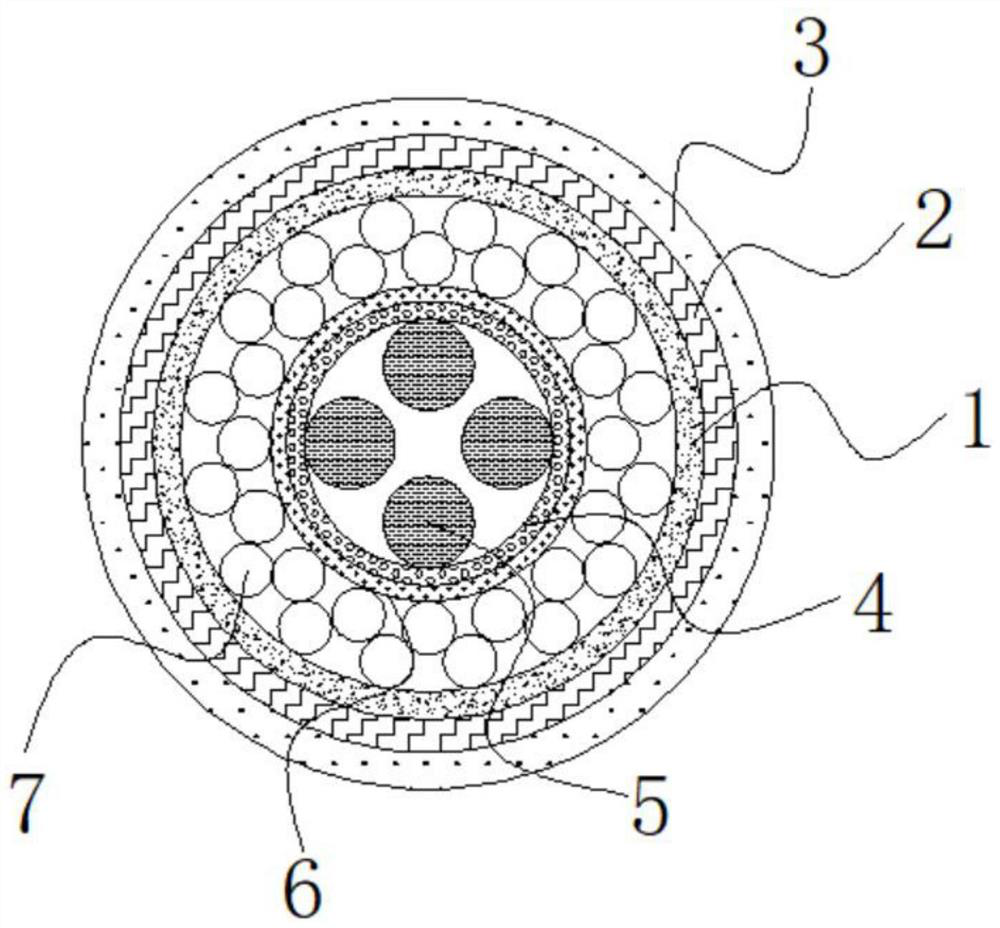

[0019] Embodiment: a kind of pressure-resistant flame-retardant optical cable, such as figure 1 As shown, it includes an inner core, an elastic layer, a shielding layer 1, a refractory layer 2 and an outer sheath 3, the outer periphery of the inner core wraps the elastic layer, and the outer periphery of the elastic layer wraps the shielding layer 1, The outer periphery of the shielding layer 1 wraps the refractory layer 2, and the outer periphery of the refractory layer 2 wraps the outer sheath 3;

[0020] The inner core includes a micro-bundle tube 4 located in the center of the optical cable and several optical fibers 5 located in the micro-bunch tube 4, and the outer periphery of the micro-bunch tube 4 is clad with a strengthening layer 6;

[0021] The elastic layer is provided with at least two layers, each layer of the elastic layer includes a number of evenly distributed elastic tubes 7, the elastic tubes 7 are arranged along the length direction of the optical cable, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com