Method for manufacturing a decorative element having a raised embossed visible surface, and decorative element manufactured by said method

A technology for decorative components and a manufacturing method, which is applied in the process of producing decorative surface effects, decorative structures, decorative arts, etc., can solve the problems that embossing does not have high shape stability, long manufacturing time, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

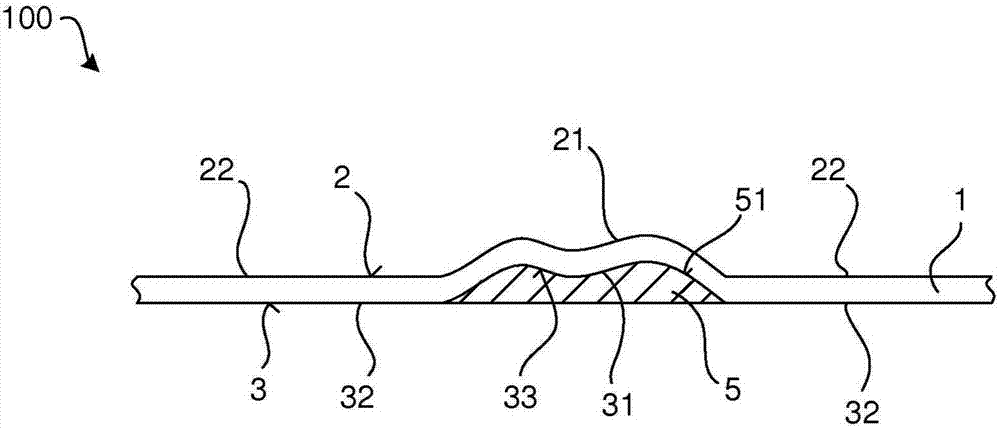

[0033] Identical or identically acting components in the exemplary embodiment and in the figures can each be provided with the same reference numerals. The elements shown and their dimensional ratios should in principle not be considered to be true to scale. Rather, some elements may be exaggeratedly bolded or shown in large sizes for better illustration and / or better understanding.

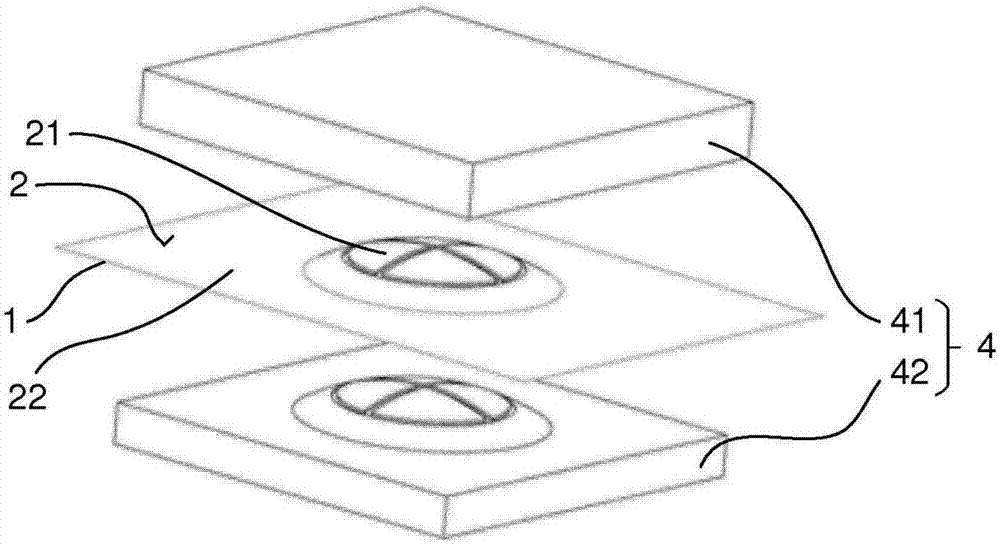

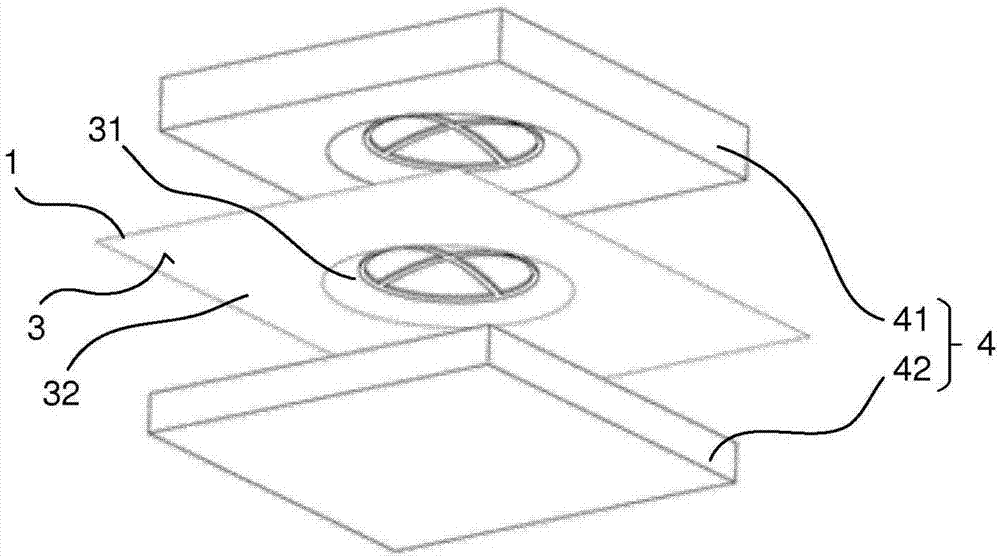

[0034] figure 1 and 2 The method for producing a decorative component with a raised embossed visible surface is shown in two different perspective views. The trim component is preferably an interior component of a vehicle.

[0035] In this method, a decorative material layer 1 and an embossing device 4 comprising a female embossing mold 41 and a male embossing mold 42 are provided. The negative embossing mold 41 and the positive embossing mold 42 are preferably made by additive manufacturing methods such as selective laser beam melting, selective laser sintering, stereolithography, multi-jet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com