Fixed ball valve, valve sealing structure and valve packing

A ball valve and sealing surface technology, applied in the field of fixed ball valves, can solve problems such as difficulty in ensuring tightness, large insertion force, and increased number of parts, and achieve the effects of preventing fluid leakage, improving tightness, and maintaining tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

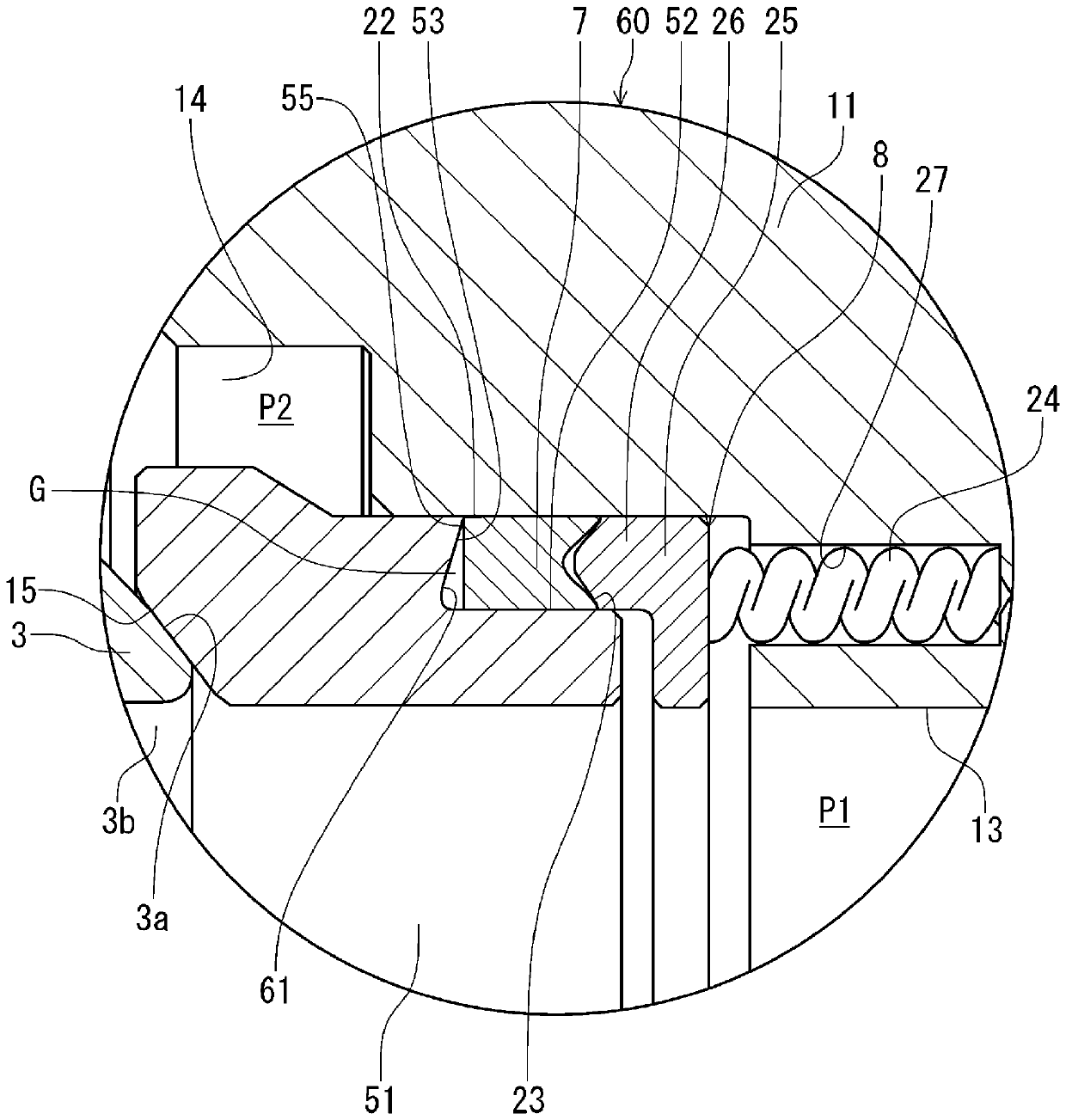

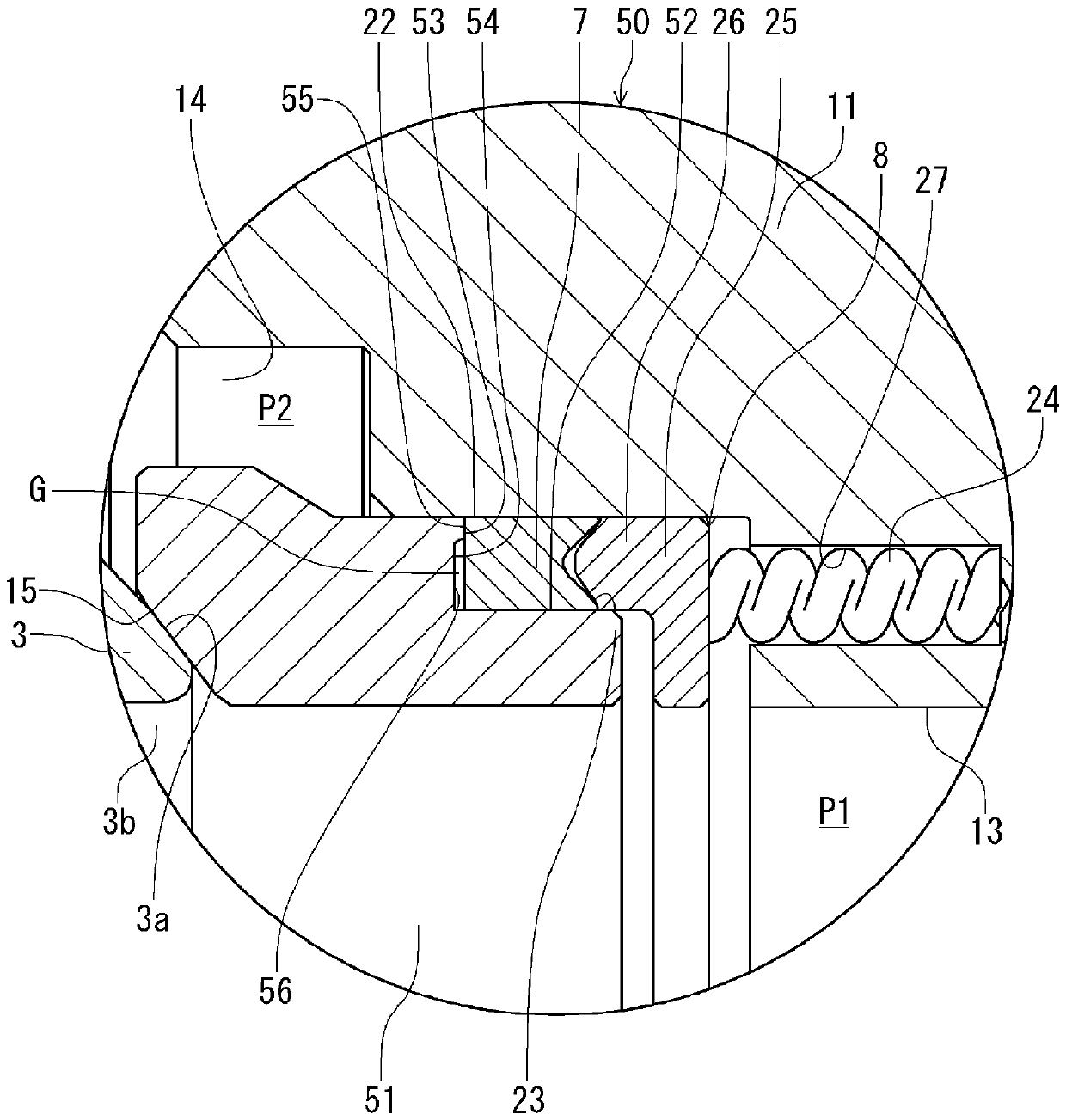

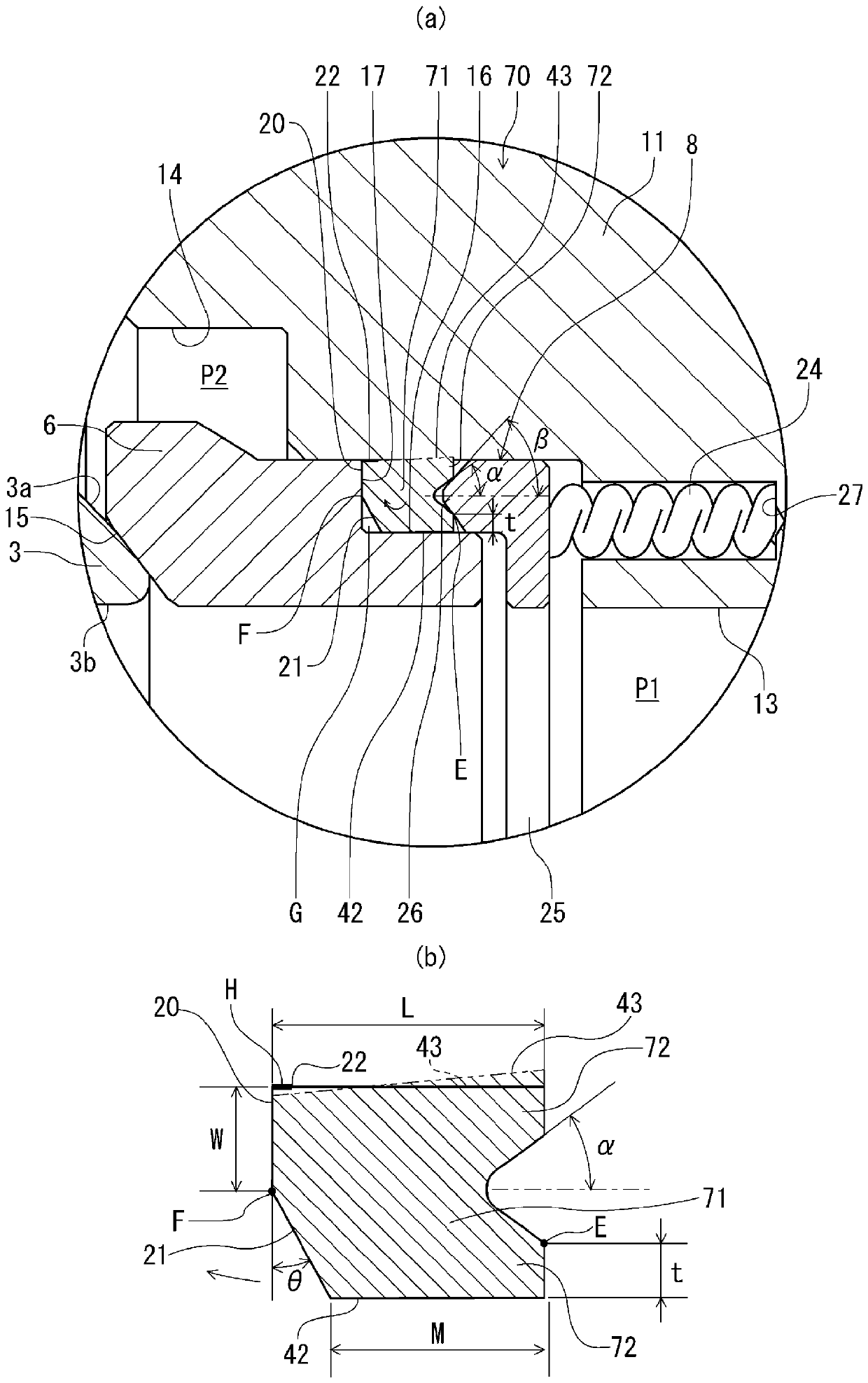

[0050] Hereinafter, embodiments of a fixed ball valve, a valve sealing structure, and a valve packing according to the present invention will be described based on the drawings. exist figure 1 The first embodiment of the fixed ball valve of the present invention is shown in figure 2 (a) means figure 1 An enlarged sectional view of part A.

[0051] figure 1 , figure 2 The fixed ball valve (hereinafter referred to as the valve main body 1) of (a) has a valve body 2, a ball 3, an upper valve stem 4, a lower valve stem 5, a ball seat 6, a packing body 7, and a pushing mechanism 8, and is particularly suitable for For use with high-pressure and high-temperature fluids. Specifically, for example, it is suitable for the use range of the highest working pressure: 10~25MPa, working temperature: -40°C~535°C, the valve main body 1 of this embodiment is assumed to have a working pressure of 10MPa, a working temperature of 400°C, and a nominal pressure of 600 pounds ( 10MPa), si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com