Soft magnetic composite material and corresponding method for preparing soft magnetic composite material

A composite material, soft magnetic technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as lack of mechanical stability, achieve high permeability, low coercivity, low eddy current The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the figures, identical reference numbers indicate identical or functionally equivalent elements.

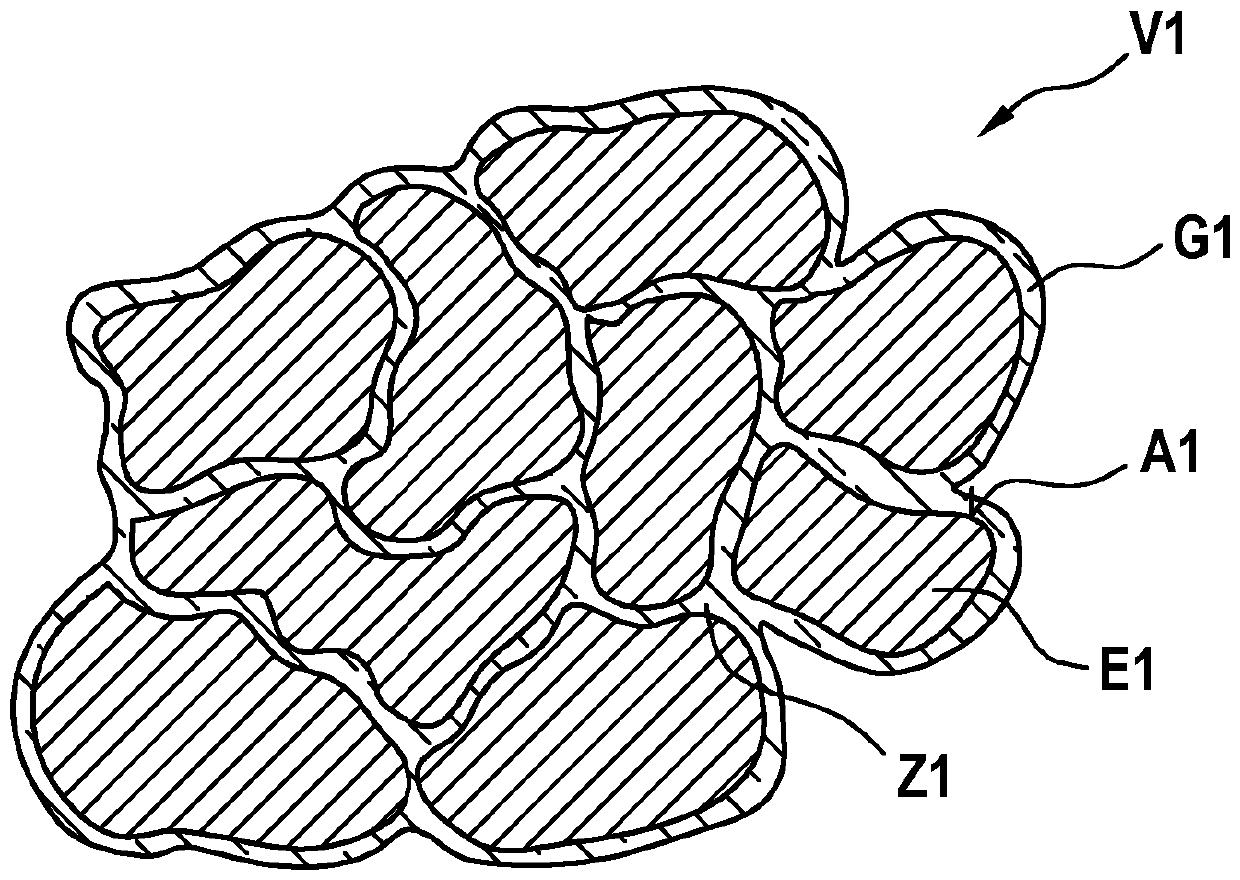

[0027] figure 1 A schematic diagram for explaining a soft magnetic composite material according to an embodiment of the present invention is shown.

[0028] Symbol V1 shows the soft magnetic composite material V1. Soft magnetic composite V1 has numerous crystalline pure iron-based particles E1 and bulk metallic glass G1. The plurality of crystalline pure iron-based particles E1 has a bulk metallic glass G1 coating, wherein the plurality of crystalline pure iron-based particles E1 are in contact with each other via the bulk metallic glass G1 coating.

[0029] From figure 1 It can be seen that a bulk metallic glass G1 is formed on the outer surface A1 of the crystalline pure iron-based particle E1. This means that crystalline pure iron-based particles adjacent via the bulk metallic glass G1 can be connected, in particular indirectly, via the bulk metallic glass G1 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com