A lead-free sodium niobate-based antiferroelectric ceramic with high saturation polarization and low remnant polarization and its preparation method

A technology of lead-free sodium niobate and lead sodium niobate, which is applied to the parts of fixed capacitors, the dielectric of fixed capacitors, etc., to achieve the effect of high flipping electric field and low remanent polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

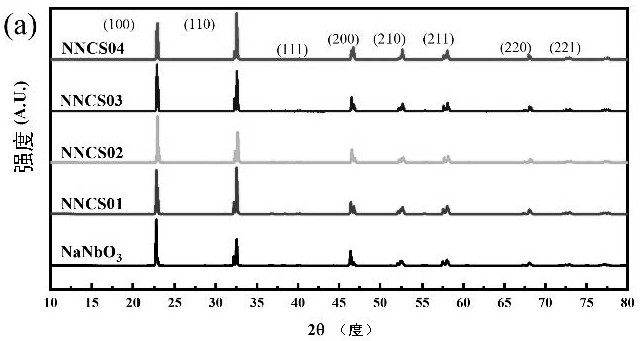

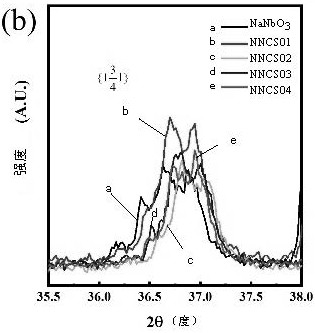

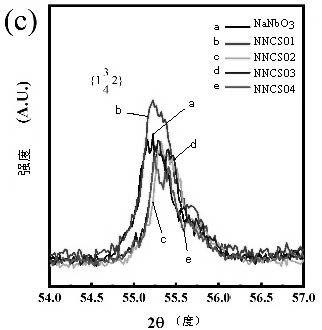

[0031] The preparation method of the sodium niobate-based antiferroelectric ceramic material of the present disclosure can be prepared by a solid phase reaction process, for example, it can include steps such as batching, mixing, briquetting, synthesis, crushing, fine grinding, molding, plastic discharge, and sintering . Hereinafter, the preparation method of the sodium niobate-based antiferroelectric ceramic material will be exemplified.

[0032] Firstly, ceramic powders were prepared by solid phase method. Specifically, the sodium source, niobium source, calcium source, and tin source are expressed as (1-x)NaNbO 3 -xCaSnO 3 The stoichiometric ratio is mixed evenly, and the NNCS ceramic powder is synthesized.

[0033] Sodium source can use sodium bicarbonate (NaHCO 3 ), sodium carbonate (Na 2 CO 3 ). Niobium source can use niobium pentoxide (Nb 2 o 5 ). Calcium source can use calcium carbonate (CaCO 3 ). Tin source can use tin dioxide (SnO 2 ).

[0034] The raw ...

Embodiment 1

[0046] The composition of the material is 0.99NaNbO 3 -0.01CaSnO 3

[0047] (1) with NaHCO 3 , Nb 2 o 5 , CaCO 3 and SnO 2 Powder as raw material, according to 0.99NaNbO 3 -0.01CaSnO 3 Stoichiometric ratio preparation, mixing by wet ball milling, briquetting after drying, and synthesis to obtain NNCS ceramic powder according to the mass ratio of raw materials: balls: alcohol = 1:8:1, mixing for 24 hours, after drying, passing 40-mesh sieve, pressed into large pieces under a pressure of 200MPa, raised to 1100°C at a heating rate of 2°C / min, and held for 4 hours to synthesize 0.99NaNbO 3 -0.01CaSnO 3 Powder;

[0048] (2) Grinding the powder obtained in step (1), passing through a 40-mesh sieve, and then finely grinding by wet ball milling, finely grinding for 48 hours according to the mass ratio of raw material: ball: deionized water=1:8:0.7 , and dry the finely ground powder. Then add 6wt.% PVA binder, granulate, briquette, age for 24 hours, pass through a 40-mesh s...

Embodiment 2

[0054] The composition of the material is 0.98NaNbO 3 -0.02CaSnO 3

[0055] Repeat the preparation method of Example 1 according to the above chemical formula composition;

[0056] (1) with NaHCO 3 , Nb 2 o 5 , CaCO 3 and SnO 2 Powder as raw material, according to 0.98NaNbO 3 -0.02CaSnO 3 Stoichiometric ratio preparation, mixing by wet ball milling, briquetting after drying, and synthesis to obtain NNCS ceramic powder according to the mass ratio of raw materials: balls: alcohol = 1:8:1, mixing for 24 hours, after drying, passing 40-mesh sieve, pressed into large pieces under a pressure of 200MPa, raised to 1100°C at a heating rate of 2°C / min, and held for 4 hours to synthesize 0.98NaNbO 3 -0.02CaSnO 3 Powder;

[0057] (2) Grinding the powder obtained in step (1), passing through a 40-mesh sieve, and then finely grinding by wet ball milling, finely grinding for 48 hours according to the mass ratio of raw material: ball: deionized water=1:8:0.7 , and dry the finely g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com