Lead-free sodium niobate-based antiferroelectric ceramic with high saturated polarization and low residual polarization and preparation method thereof

A technology of lead-free sodium niobate and lead sodium niobate, which is used in the parts of fixed capacitors, the dielectric of fixed capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

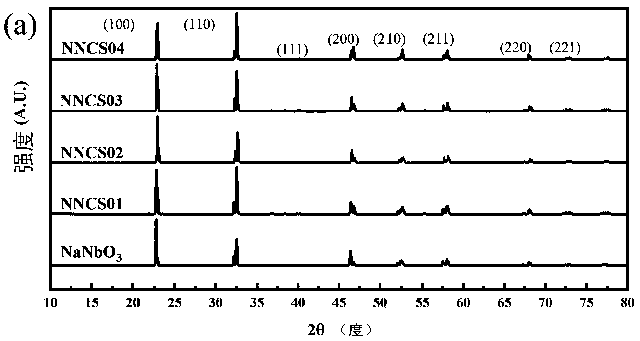

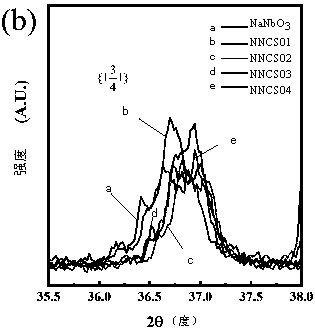

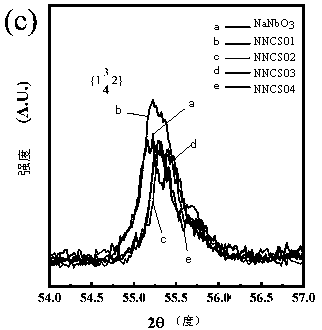

Image

Examples

preparation example Construction

[0031] The preparation method of the sodium niobate-based antiferroelectric ceramic material of the present disclosure can be prepared by a solid phase reaction process, for example, it can include steps such as batching, mixing, briquetting, synthesis, crushing, fine grinding, molding, plastic discharge, and sintering . Hereinafter, the preparation method of the sodium niobate-based antiferroelectric ceramic material will be exemplified.

[0032] Firstly, ceramic powders were prepared by solid phase method. Specifically, the sodium source, niobium source, calcium source, and tin source are expressed as (1-x)NaNbO 3 -xCaSnO 3 The stoichiometric ratio is mixed evenly, and the NNCS ceramic powder is synthesized.

[0033] Sodium source can use sodium bicarbonate (NaHCO 3 ), sodium carbonate (Na 2 CO 3 ). Niobium source can use niobium pentoxide (Nb 2 o 5 ). Calcium source can use calcium carbonate (CaCO 3 ). Tin source can use tin dioxide (SnO 2 ).

[0034] The raw ...

Embodiment 1

[0046] The composition of the material is 0.99NaNbO 3 -0.01CaSnO 3

[0047] (1) with NaHCO 3 , Nb 2 o 5 , CaCO 3 and SnO 2 Powder as raw material, according to 0.99NaNbO 3 -0.01CaSnO 3 Stoichiometric ratio preparation, mixing by wet ball milling, briquetting after drying, and synthesis to obtain NNCS ceramic powder according to the mass ratio of raw materials: balls: alcohol = 1:8:1, mixing for 24 hours, after drying, passing 40-mesh sieve, pressed into large pieces under a pressure of 200MPa, raised to 1100°C at a heating rate of 2°C / min, and held for 4 hours to synthesize 0.99NaNbO 3 -0.01CaSnO 3 Powder;

[0048] (2) Grinding the powder obtained in step (1), passing through a 40-mesh sieve, and then finely grinding by wet ball milling, finely grinding for 48 hours according to the mass ratio of raw material: ball: deionized water=1:8:0.7 , and dry the finely ground powder. Then add 6wt.% PVA binder, granulate, briquette, age for 24 hours, pass through a 40-mesh s...

Embodiment 2

[0054] The composition of the material is 0.98NaNbO 3 -0.02CaSnO 3

[0055] Repeat the preparation method of Example 1 according to the above chemical formula composition;

[0056] (1) with NaHCO 3 , Nb 2 o 5 , CaCO 3 and SnO 2 Powder as raw material, according to 0.98NaNbO 3 -0.02CaSnO 3 Stoichiometric ratio preparation, mixing by wet ball milling, briquetting after drying, and synthesis to obtain NNCS ceramic powder according to the mass ratio of raw materials: balls: alcohol = 1:8:1, mixing for 24 hours, after drying, passing 40-mesh sieve, pressed into large pieces under a pressure of 200MPa, raised to 1100°C at a heating rate of 2°C / min, and held for 4 hours to synthesize 0.98NaNbO 3 -0.02CaSnO 3 Powder;

[0057] (2) Grinding the powder obtained in step (1), passing through a 40-mesh sieve, and then finely grinding by wet ball milling, finely grinding for 48 hours according to the mass ratio of raw material: ball: deionized water=1:8:0.7 , and dry the finely g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Saturation polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com