Polyphase ac electric motor

An AC motor, out-of-phase technology, used in electric components, synchronous motors with stationary armatures and rotating magnets, electromechanical devices, etc. The effect of reducing the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, embodiments of the present invention will be described.

[0047] (A) Explanation of embodiment of the present invention

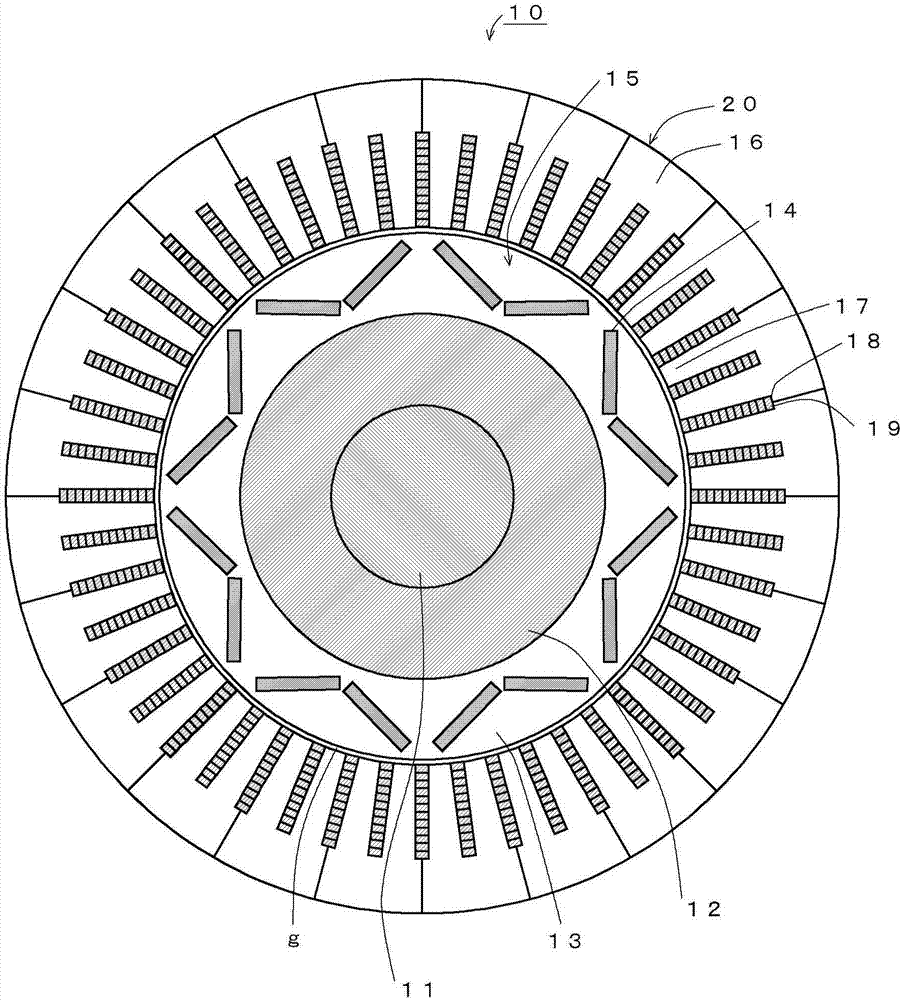

[0048] figure 1 It is a figure which shows the structural example of the polyphase AC motor which concerns on embodiment of this invention. Such as figure 1 As shown, the polyphase AC motor 10 according to the embodiment of the present invention includes: a stator 20 formed in a substantially cylindrical shape; The concentric rotating shaft 11 is, for example, used as a drive source similar to an internal combustion engine in a hybrid vehicle or an electric vehicle, or has a performance suitable for being mounted in a wheel.

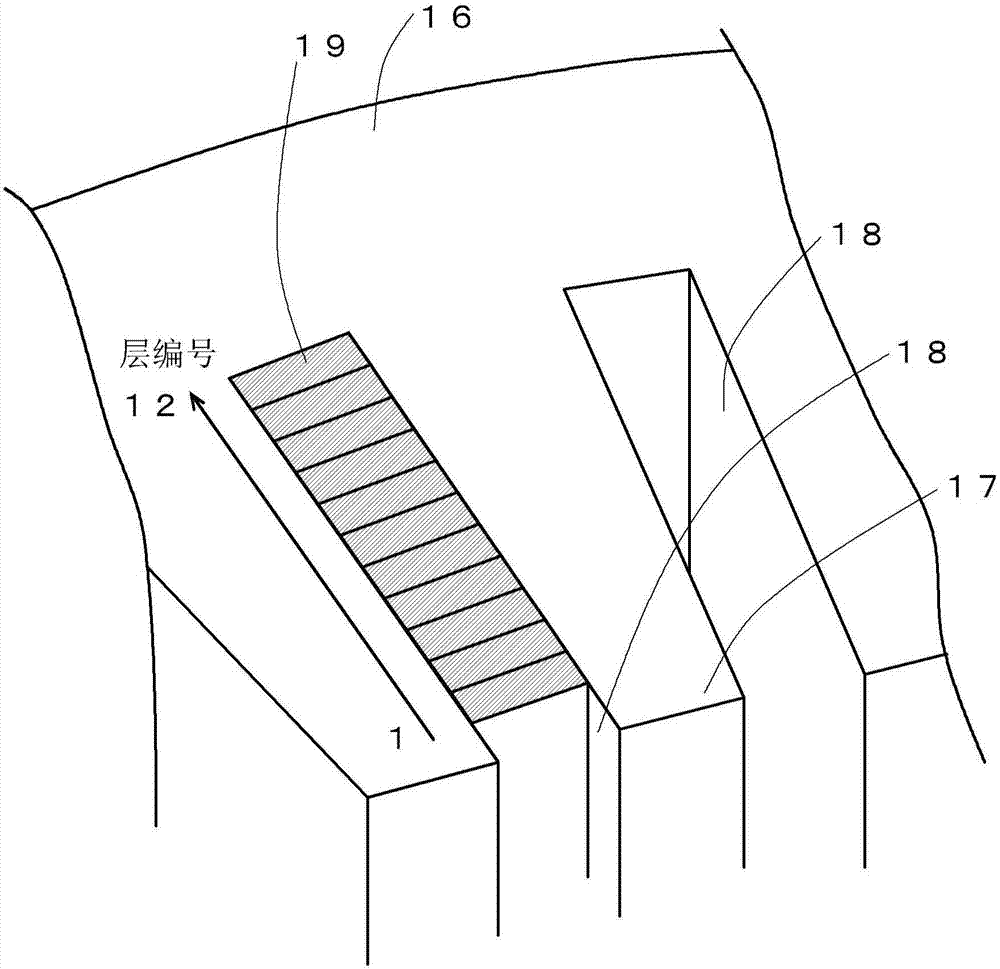

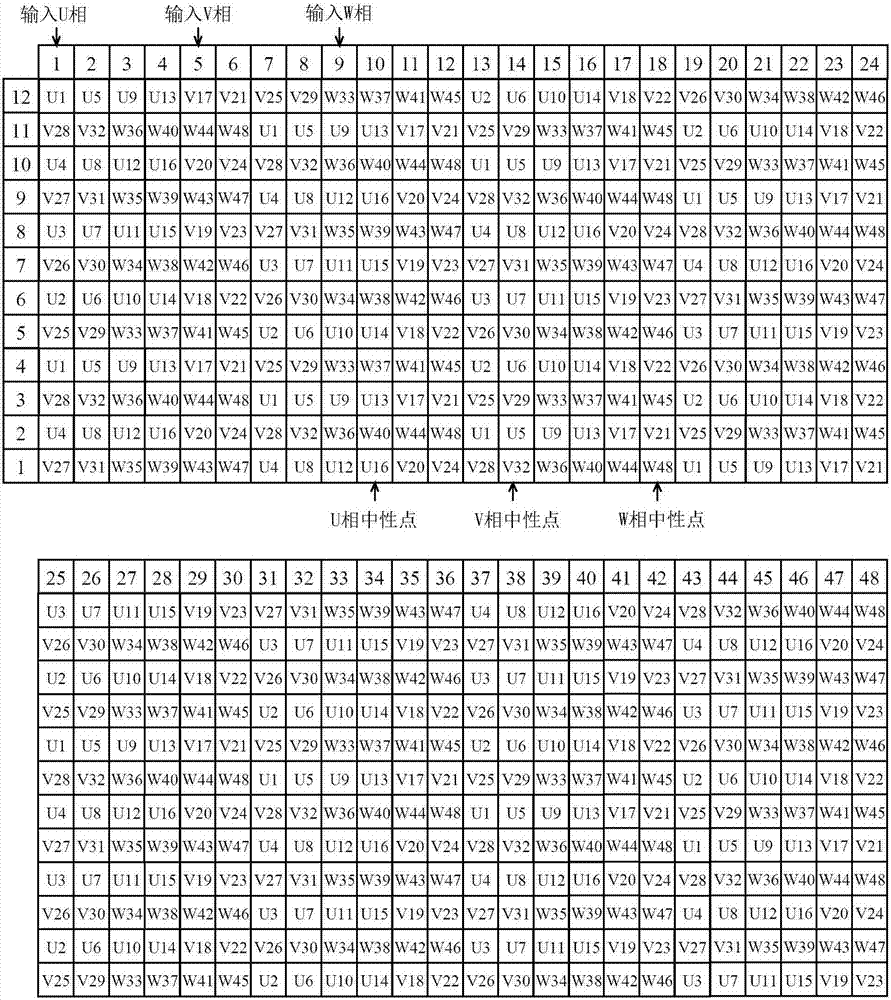

[0049] Such as figure 1 and figure 2 As shown, the stator 20 is composed of a stator member 16 formed with a plurality of teeth 17 whose inner peripheral surface faces the outer peripheral surface of the rotor 15 via a gap g. Extend in the normal direction of the axis. Slots 18 are formed between the teeth 17, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com