Integrated tandem-type small-modulus gear hob and processing method and use method thereof

A technology of small modulus gear and integral hob, which is applied in gear tooth manufacturing tools, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problem of increasing the frequency of hob tool change and regrinding, reducing the number of times of tool shifting, and hob Increased installation error and other issues, to achieve the effect of reducing the frequency of tool change and regrinding, reducing the cost of use, and reducing the installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

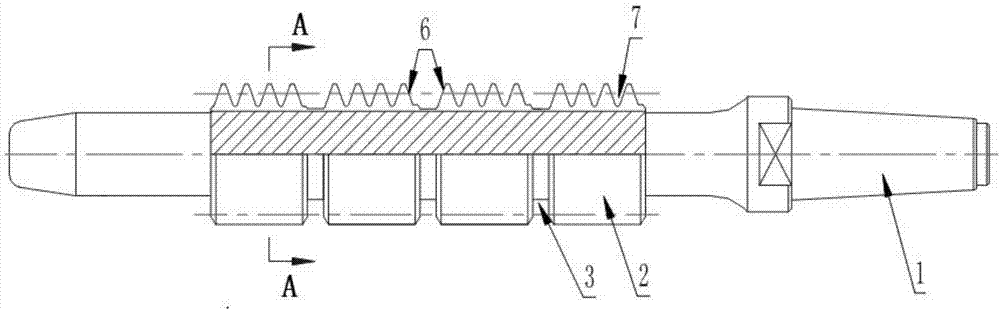

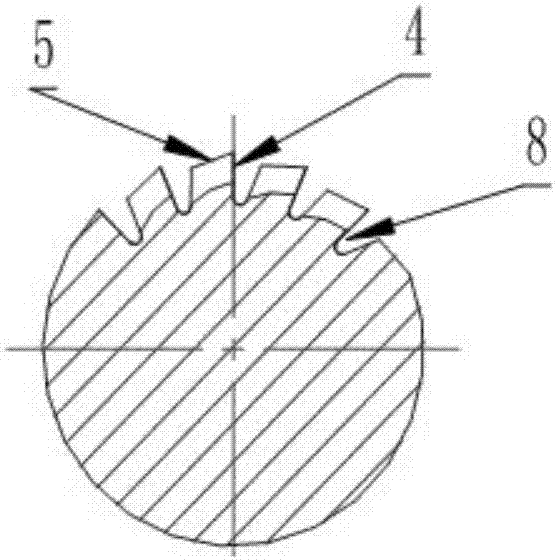

[0019] Embodiment of the present invention: the structural diagram of the tandem small modulus gear integral hob is as follows figure 1 and figure 2 As shown, it includes a cutter bar 1 and a hob cutter body 2 that is arranged on the cutter bar 1 and is connected with the cutter bar 1 as a whole. Three annular isolation grooves 3 with equal distances are arranged on the hob cutter body 2. The annular isolation grooves 3. Isolate the hob cutter body 2 to form four independent hobs connected in series. Each relatively independent hob is composed of a rake face 4 , a top edge relief angle 5 , a side edge 6 , a spiral groove 7 and a chip flute 8 . The rake face 4 of each relatively independent hob is on the same plane along the axial direction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com