Power assembly for hybrid vehicle and combined type speed changer of power assembly

A technology for hybrid vehicles and transmissions, which is applied to the layout of multiple prime movers of hybrid vehicles and general-purpose power plants, and motor vehicles. Good performance and economy, and the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0034] Powertrain for Hybrid Vehicles

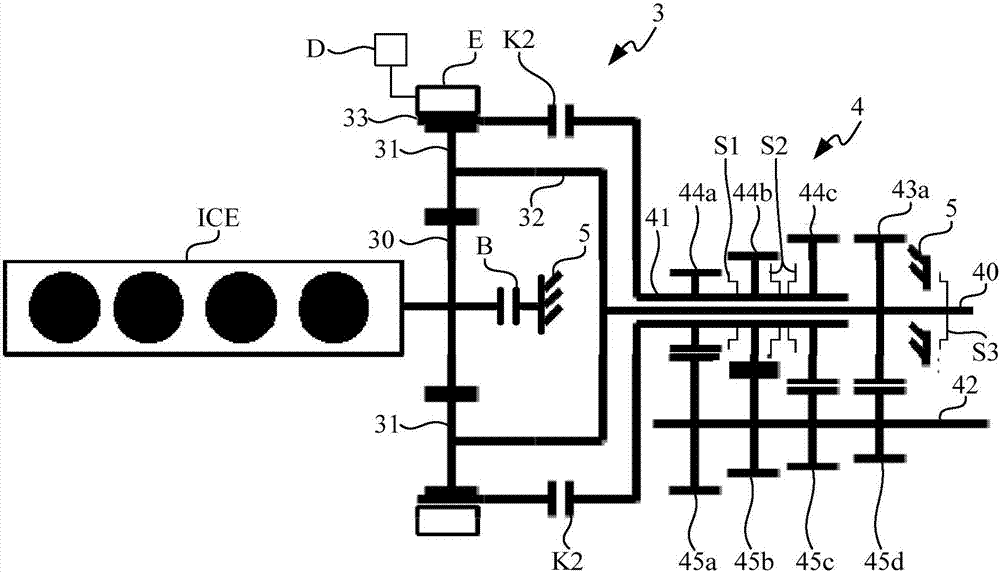

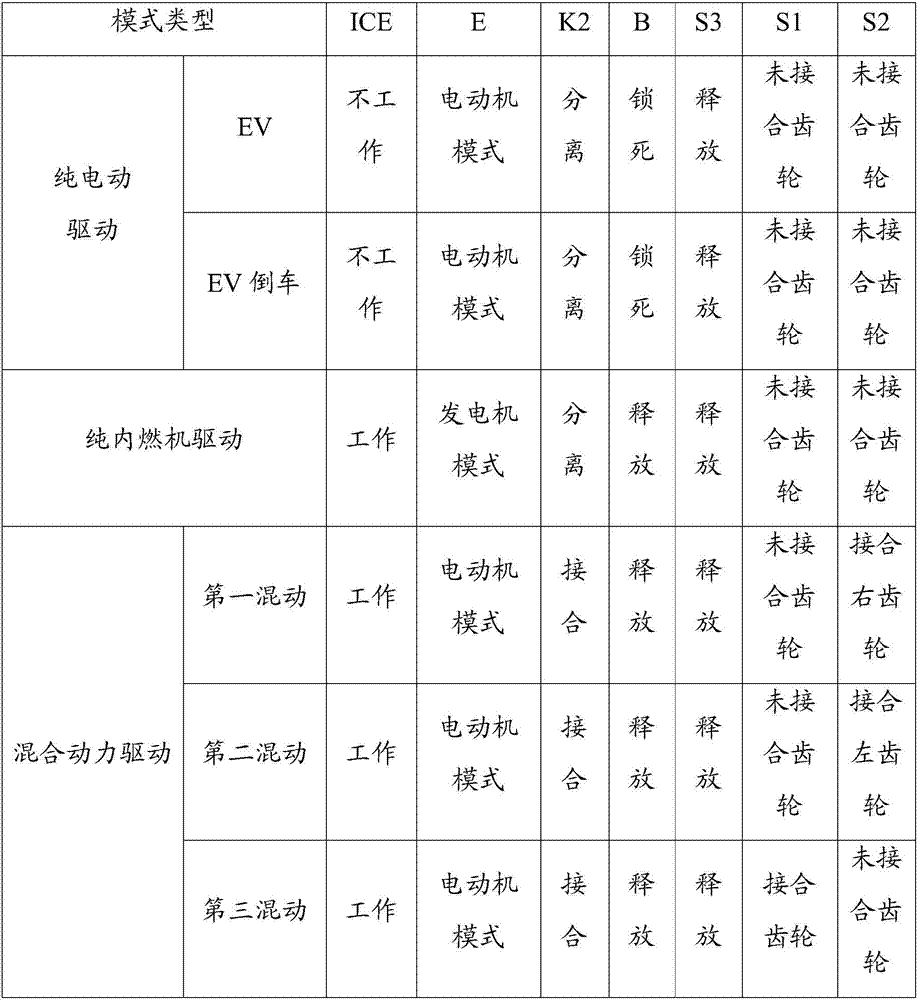

[0035] Such as figure 1 As shown, the powertrain of the hybrid vehicle in this embodiment includes an internal combustion engine ICE, a motor E, and a combined transmission (not marked). The internal combustion engine ICE and the motor E are used as power sources, and the output power is transmitted to the wheels through the combined transmission.

[0036] In this embodiment, the internal combustion engine ICE takes a four-cylinder engine as an example. In a modified example of the present embodiment, the internal combustion engine ICE may be an engine with another number of cylinders.

[0037] In the technical solution of the present invention, in addition to being used as a power source (working in the motor mode), the motor E is also used as a generator to convert the power output by the internal combustion engine ICE into electrical energy and store it in the battery D. Regarding how the motor E will The conversion of the power o...

no. 2 example

[0121] Powertrain for Hybrid Vehicles

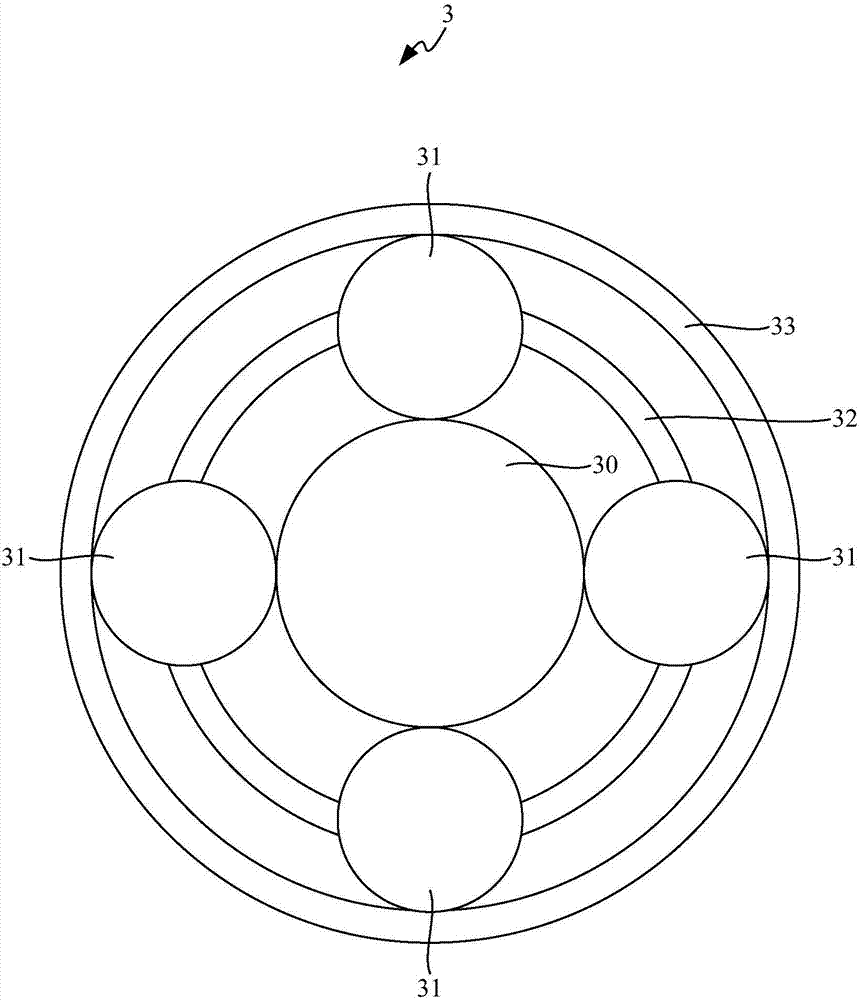

[0122] One of the differences between the second embodiment and the first embodiment is that in the second embodiment, as Figure 4 As shown, the combined transmission further includes a second power coupling unit K1. One end of the second power coupling unit K1 is connected to the planetary gear 31 and the other end is connected to the planet carrier 32 , and can be switched between an engaged state and a disengaged state. When the second power coupling unit K1 is in the engaged state, torque transmission between the planetary gear 31 and the planetary carrier 32 is established. When the second power coupling unit K1 is in the disengaged state, the torque transmission between the planetary gear 31 and the planetary carrier 32 is interrupted.

[0123] The second difference between the second embodiment and the first embodiment is that in the second embodiment, as Figure 4 As shown, there are two first gears on the first input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com