A kind of preparation method of methyl tert-amyl ether

A technology of methyl tert-amyl ether and methanol, which is applied in the field of preparation of methyl tert-amyl ether, can solve the problems of increased by-products, increased side reactions of oligomerization, corrosion of equipment, etc., to improve specific surface area, reduce loss rate, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

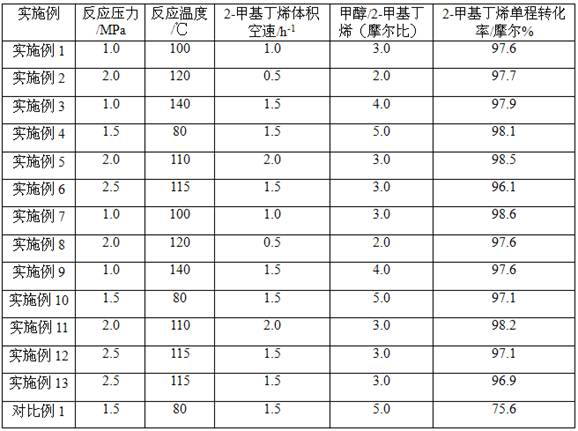

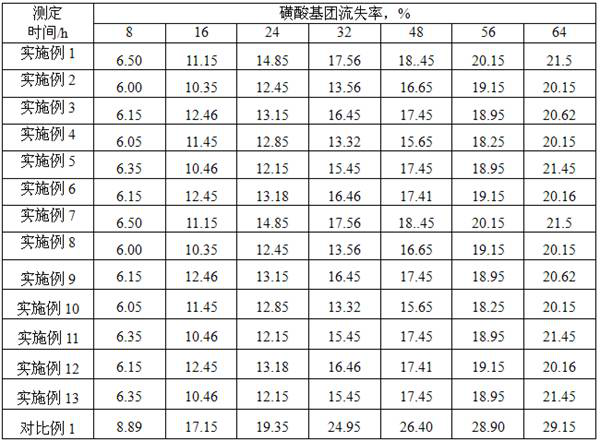

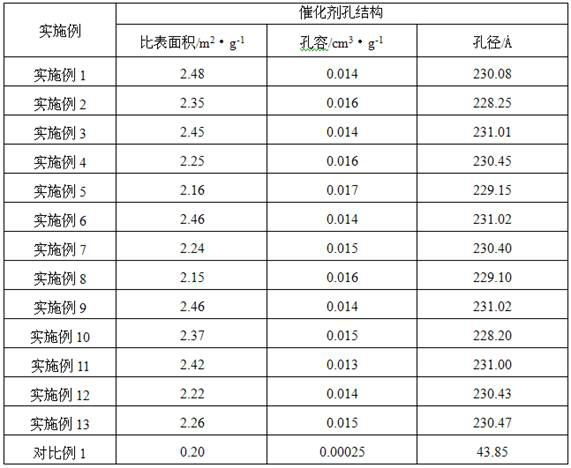

Examples

Embodiment 1

[0046] (1) Preparation of DNW-Ⅱ strong acid cation exchange resin:

[0047] There are many preparation methods for DNW-II type temperature-resistant strong acid cation exchange resin catalysts, and the resin catalysts prepared according to the methods in the prior art are applicable to the present invention. The resin catalysts in this embodiment adopt polymerization, extraction, chlorination, The five-step preparation of sulfonation and stabilization of active groups is as follows: polymerize to obtain styrene-divinylbenzene copolymer microspheres, swell, mix the swollen copolymer with benzene, and stir and extract at 180°C and 2.0MPa 16h, cool down, discharge benzene, then place the copolymer in absolute ethanol for extraction treatment under the same conditions, wash, chlorinate, sulfonate, and stabilize active groups in turn on the purified copolymer to obtain DNW-II Type temperature resistant strong acid cation exchange resin catalyst.

[0048] (2) Pretreatment of DNW-Ⅱ ...

Embodiment 2

[0051] Except that ethanol and n-butanol were used instead of isopropanol and sec-butanol in (2), other conditions were the same as in Example 1.

Embodiment 3

[0053] Except that ethanol and isopropanol were used instead of isopropanol and sec-butanol in (2), other conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com