New-energy heat-conductive foaming silica gel and preparation technology thereof

A technology of foamed silica gel and preparation process, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high cost, large proportion of thermally conductive silica gel, and increased battery volume, etc., and achieves light specific gravity, reduced weight, and reduced The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to specific embodiments.

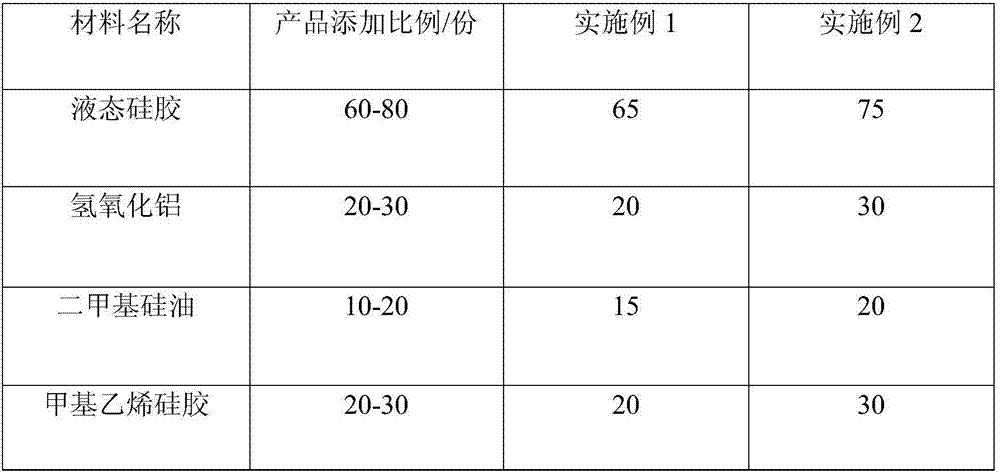

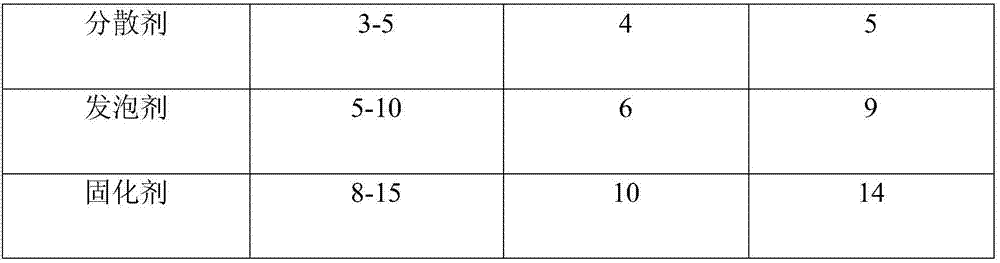

[0015] Table 1 below is the material formulation of the present invention and Examples 1-2.

[0016] Table 1 Material formula

[0017]

[0018]

[0019] Batching process 1. First put the liquid silica gel, dimethyl silicone oil and methyl vinyl silica gel into the internal mixer and heat it to 100-150 degrees Celsius for high-speed stirring, stirring at a speed of 3000 rpm (3000 rpm), stirring for 30-50 minutes;

[0020] 2. The stirred silica gel mixture is put into the dispersing mixer again, and aluminum hydroxide, foaming agent and dispersing agent are added in sequence for dispersing and stirring. The time is 30-40 minutes, and then the curing agent is added for stirring for 20-30 minutes, and the silica gel raw material is taken out to obtain a thermally conductive foamed silica gel mixture.

[0021] Production process 1. Put the stirred raw materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com