A kind of polyester dyeing carrier and preparation method thereof

A technology of carrier and polyester, which is applied in the field of polyester dyeing carrier and its preparation, can solve the problems of high cost of N-alkylpyrrolidone, difficulty in popularization and acceptance, and odor of cloth surface, etc., and achieve lower dyeing temperature, simple steps, and reliable process high control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

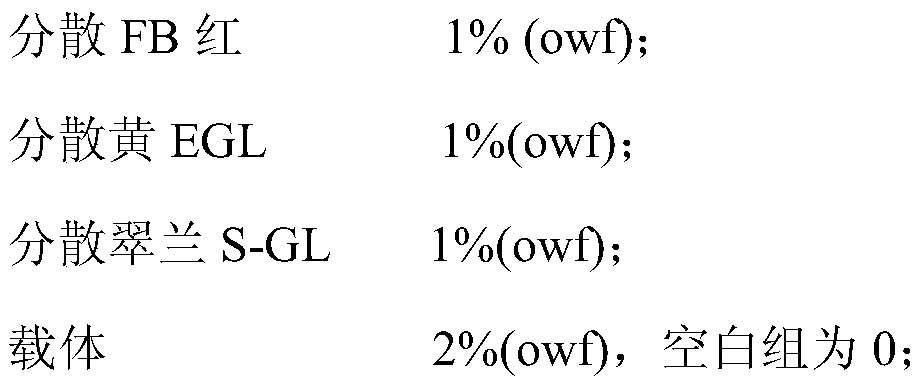

Examples

Embodiment 1

[0044] In this embodiment, a polyester dyeing carrier is provided, the proportions of each component in the polyester dyeing carrier are: 60% diethylene glycol phthalate, 10% dodecylbenzenesulfonate Ammonium Acetate, 30% AEO-9. The preparation method of the polyester dyed carrier is as follows.

[0045] Step 101. Using p-toluenesulfonic acid as a catalyst, add phthalic anhydride to ethylene glycol, keep the temperature at 60°C for 1 hour, raise the temperature to 110°C, and carry out esterification under the condition of vacuum degree -0.07MPa React for 2h to obtain diethylene glycol phthalate. Wherein, the mol ratio of phthalic anhydride and ethylene glycol is 1:2.2, and the addition of p-toluenesulfonic acid is 0.5% of the total mass of phthalic anhydride and ethylene glycol;

[0046] Step 102. The diethylene glycol phthalate obtained in step 101 and benzoic acid were dehydrated and esterified for 3 hours at a temperature of 140° C. and a vacuum of -0.07 MPa under the acti...

Embodiment 2

[0049] In this embodiment, a polyester dyeing carrier is provided. The proportions of the components in the polyester dyeing carrier are: 60% dipropylene glycol phenylacetate phthalate, 15% sodium dodecylbenzene sulfonate, and 25% flat plus O-20. The preparation method of the polyester dyeing carrier specifically includes the following steps.

[0050] Step 101. Using p-toluenesulfonic acid as a catalyst, add phthalic anhydride to propylene glycol, keep the temperature at 70°C for 1.2h, raise the temperature to 120°C, and carry out esterification under the condition of vacuum degree -0.08MPa 2.2h, to obtain dipropylene glycol phthalate. Wherein, the mol ratio of phthalic anhydride and propylene glycol is 1:2.4, and the addition of the p-toluenesulfonic acid is 1% of the total mass of phthalic anhydride and propylene glycol;

[0051] Step 102. The dipropylene glycol phthalate obtained in step 101 and phenylacetic acid were dehydrated and esterified for 3.2 hours at a temperatu...

Embodiment 3

[0054] In this embodiment, a polyester dyeing carrier is provided. The proportions of the components in the polyester dyeing carrier are: 60% diethylene glycol cinnamate phthalate, 20% calcium dodecylbenzenesulfonate, and 20% TO-10. The preparation method of the polyester dyeing carrier specifically includes the following steps.

[0055] Step 101. Using p-toluenesulfonic acid as a catalyst, add phthalic anhydride to diethylene glycol, keep the temperature at 80°C for 1.6h, raise the temperature to 130°C, and carry out under the condition of vacuum degree -0.09MPa After 2.5 hours of esterification, diethylene glycol phthalate was obtained. Wherein, the mol ratio of phthalic anhydride and diethylene glycol is 1:2.6, and the addition of p-toluenesulfonic acid is 2% of the total mass of phthalic anhydride and diethylene glycol;

[0056] Step 102. The diethylene glycol phthalate and cinnamic acid obtained in step 101 are dehydrated and esterified under the conditions of 160° C. a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com