Shallow coal seam water protection mining method and application thereof

A water-retaining mining and coal seam technology, which is applied in ground mining, mining equipment, earth drilling and mining, etc., can solve the problems of difficult coordination between mining and filling, complex filling system, and large filling space, so as to achieve the safety of water resource protection mining High efficiency, high efficiency coal output, and high coal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A water conservation mining method for shallow coal seams, which is applied to shallow coal seams with an isolation ratio of 18 to 35, said method comprising the following steps:

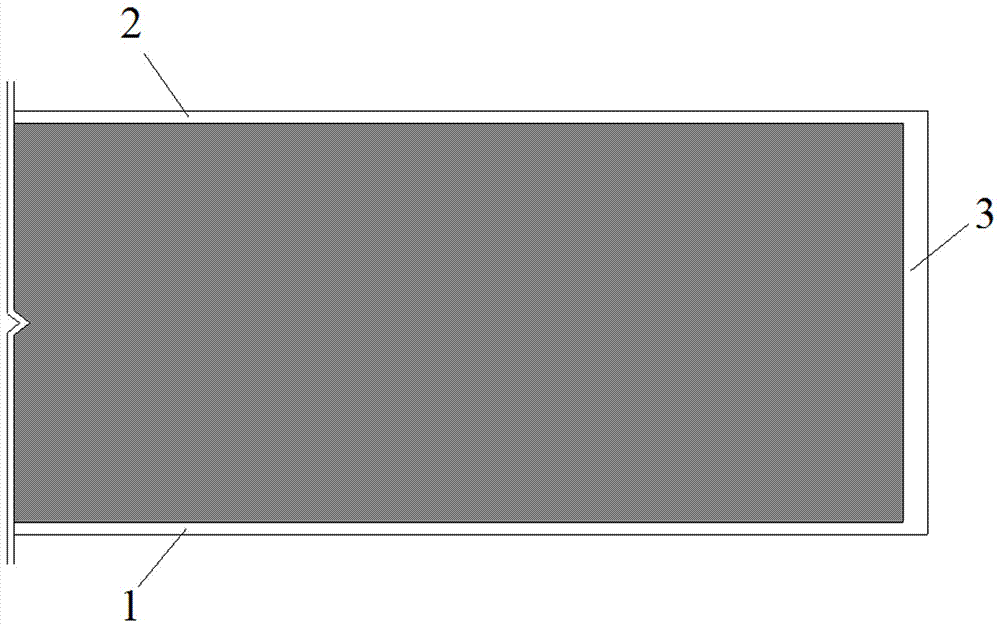

[0038] Step 1. The advancing length of the working face is 350 m and the width is 150 m. figure 1 , the main transportation lane 1 is arranged on one side of the edge of the working face, and the auxiliary transportation lane 2 is arranged on the other side. The layout of the main transportation lane 1 and the auxiliary transportation lane 2 follows the principle of "overhead mining and bottom filling", that is, the main transportation lane 1 is arranged at a lower level, coal is transported downward, and the auxiliary transportation lane is arranged at a higher level , the filling material is filled from top to bottom, and the filling material is gangue.

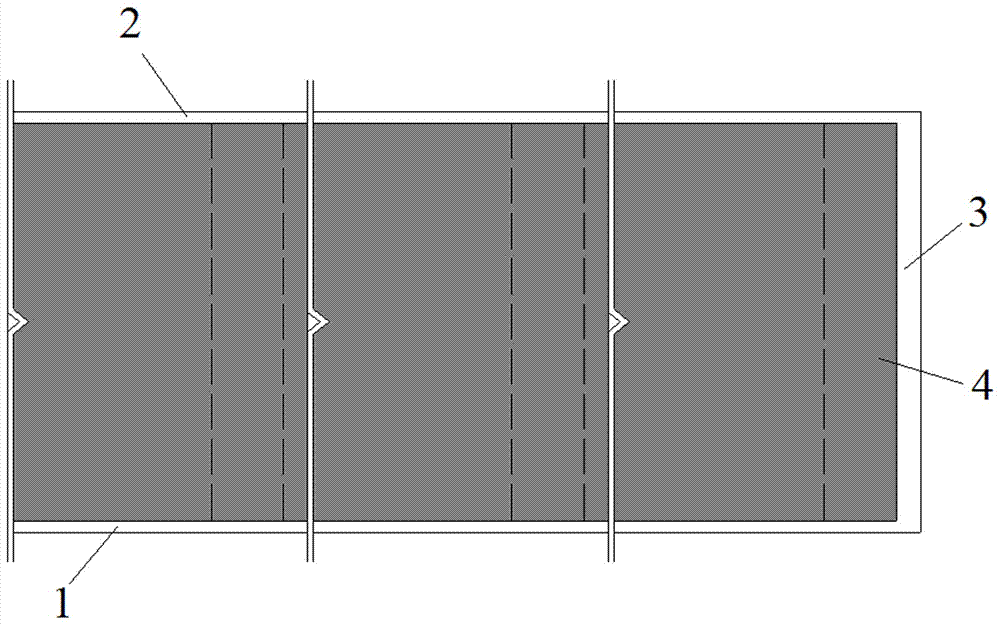

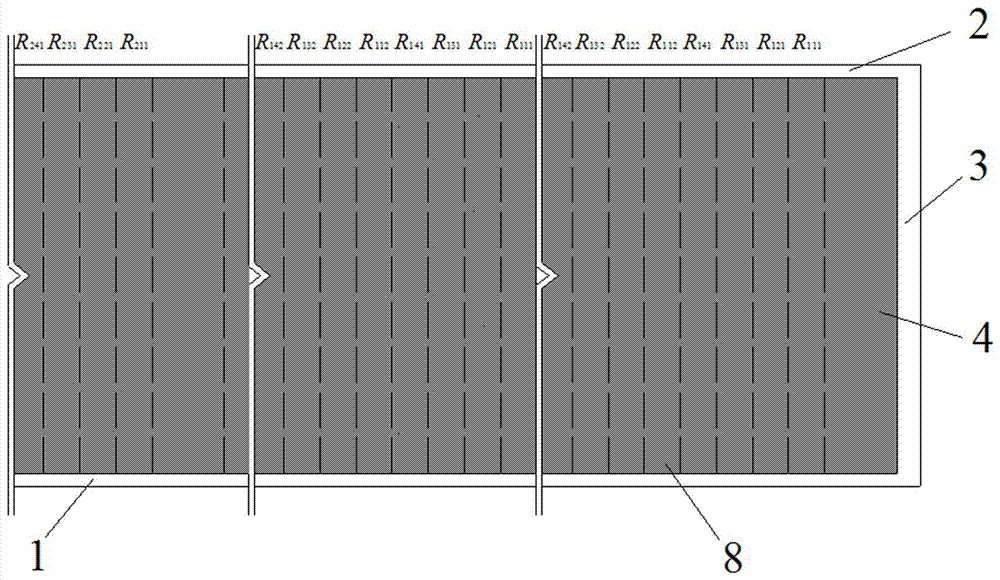

[0039] Step 2. Divide the working face perpendicular to the strike direction into three groups of mining cycles, refer to figure 2 , ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com