An alarm gas smelting furnace

A smelting furnace and gas technology, applied in the field of alarm gas smelting furnaces, can solve the problems of difficult control of combustion temperature, uneven fuel mixing, poor smelting accuracy, etc., to ensure safe and orderly operation, smelting efficiency reduction, and accurate combustion temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

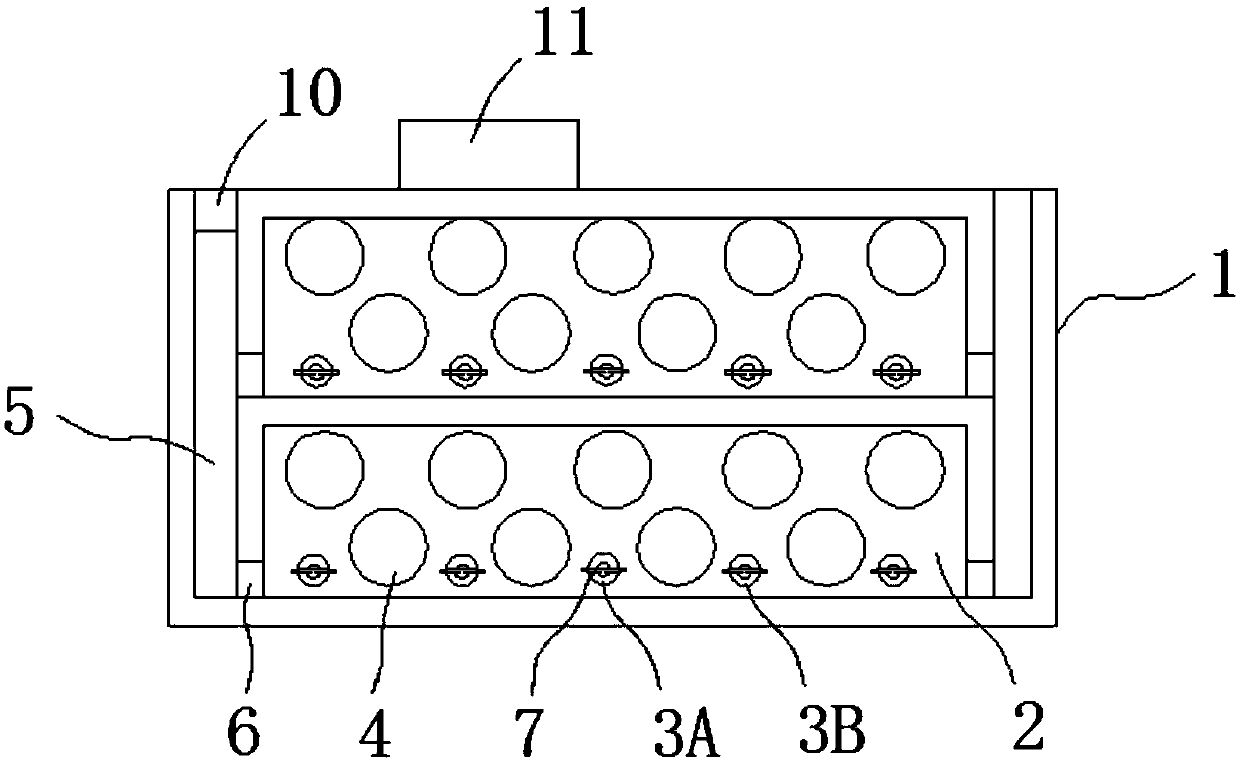

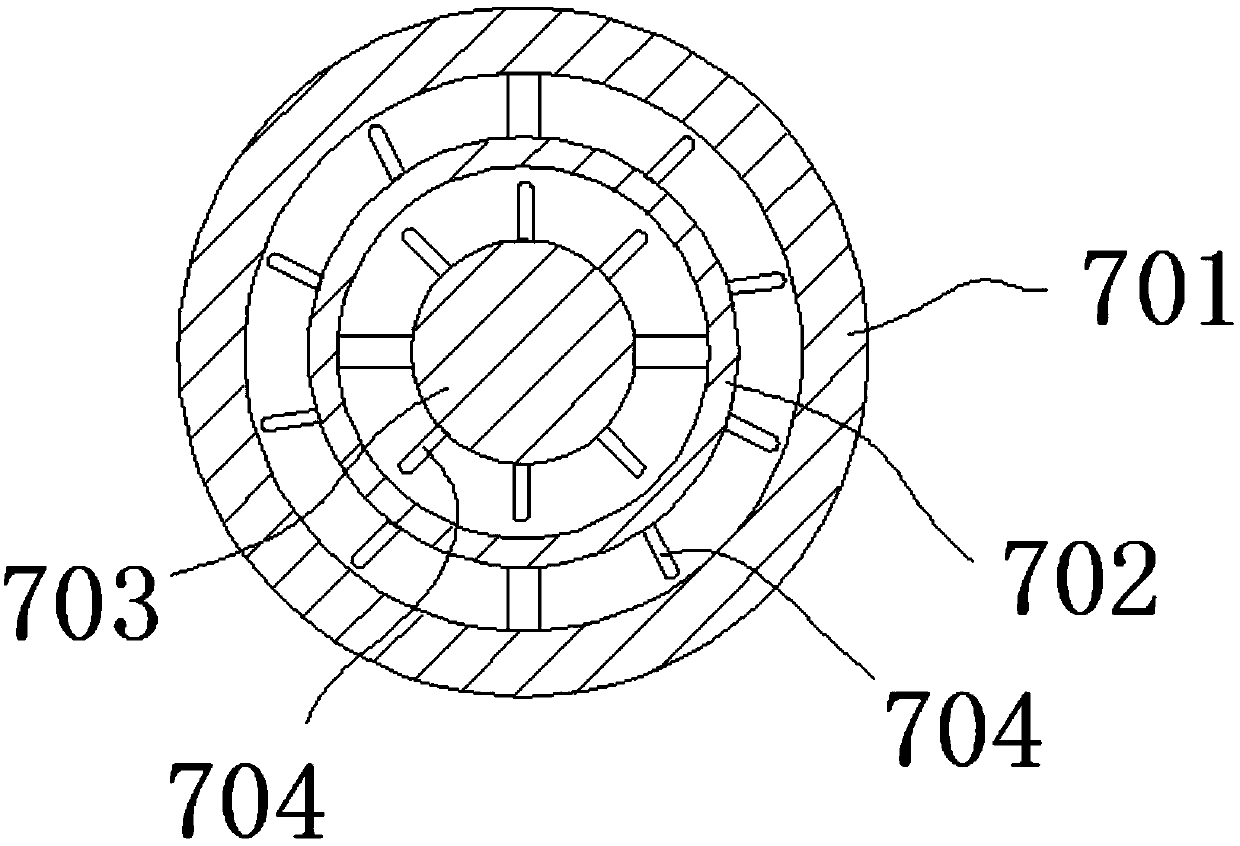

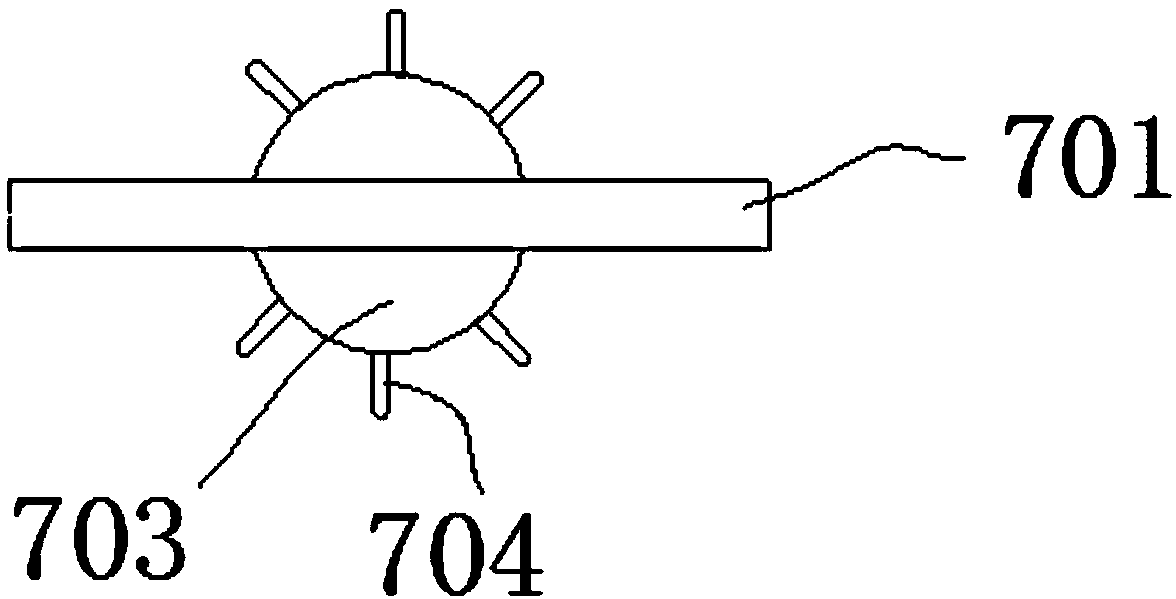

[0028] like Figure 1 to Figure 5 As shown, an alarm gas smelting furnace includes a vertical furnace body 1, and the vertical furnace body 1 is provided with multiple layers of vertically stacked combustion chambers 2, and one side wall of each layer of the combustion chamber 2 is provided with a A plurality of first nozzles 3A for injecting gas and a plurality of second nozzles 3B for injecting air; each layer of the combustion chamber 2 is provided with a plurality of smelting tanks 4; the tank mouth of the smelting tank 4 Both are arranged on the outer wall of the vertical furnace body 1, and two flues 5 are also arranged in the vertical furnace body 1, and the two flues 5 are respectively located at both ends of the multi-layered c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com