Multi-vibrating stand parallel-excitation movement synchronization debugging method

A debugging method and technology of shaking table, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of lack of mature products, immature development of phase synchronization controller, etc., and achieve the effect of effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

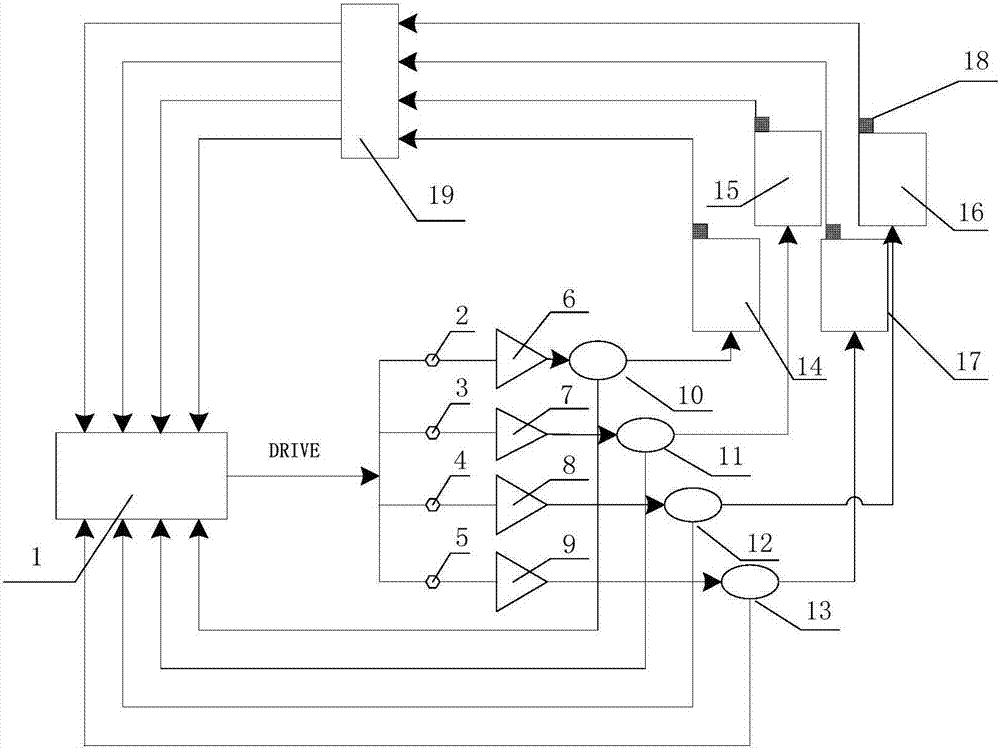

[0033] A method for synchronous debugging of multiple vibrating tables parallel excitation motions of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] see figure 1 , figure 1 A schematic diagram of a four-table parallel-excited vibration test system in a specific embodiment of the present invention is shown; wherein, this specific embodiment uses four parallel-excited vibration tables. The vibration test system of the present invention includes: a vibration controller, a phase shifter, a power amplifier, a Hall current sensor, a vibration table, a control sensor and a signal regulator.

[0035] figure 1 The middle vibration controller 1 sends out the Drive driving signal, passes through the phase shifters 2, 3, 4, and 5, and then enters the power amplifiers 6, 7, 8, and 9 to amplify the signals, and then drives the vibration tables 14, 15, 16, and 17. shaker motion. The control sensors installed on the four vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com