Vertical falling film heat exchanger

A technology of heat exchanger and falling film, which is applied to evaporator accessories, vertical tube evaporators, chemical instruments and methods, etc., can solve the problems of uneven distribution of air flow and affecting heat exchange efficiency, so as to achieve beneficial distribution effect and improve exchange rate. Thermal efficiency, effect of reducing liquid film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

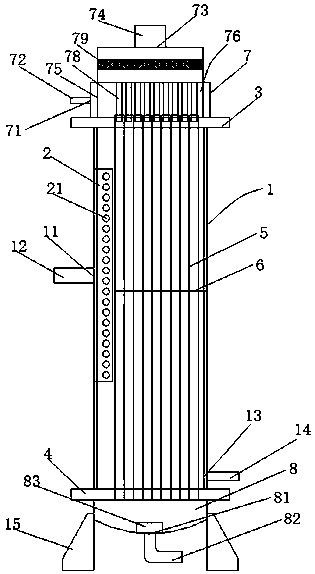

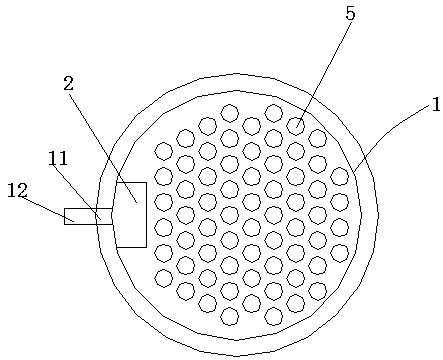

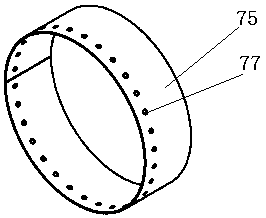

[0030] refer to Figure 1~Figure 3 , a vertical falling film heat exchanger according to the present invention, the heat exchanger comprises: a cylinder 1, vertically arranged, with openings at both ends, and an air inlet 11 is opened on the upper part of one side wall, on which An air inlet pipe 12 is inserted, and a liquid outlet 13 is opened on the lower part of the other side wall, and a liquid outlet pipe 14 is inserted on it; an exhaust distribution plate 2 is arranged on the cylinder 1 along the height direction of the cylinder 1 to open an air inlet On one side of the inner wall of 11, a number of distribution air holes 21 are set at intervals along the height direction of the cylinder body 1 on both sides to form a uniform distribution of the gas entering from the air inlet 11; the upper and lower tube plates 3 and 4 are respectively arranged on the cylinder body The upper and lower open ends of the body 1; a number of heat exchange tubes 5 are arranged at intervals a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com