Uniform energy-saving fusion mixing device

A melt-mixing and uniform technology, applied in mixers, transportation, packaging, dissolution, etc., can solve the problems of uneven mixing of materials and easy bonding, and achieve the effect of uniform melting and mixing of materials, increasing the contact area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

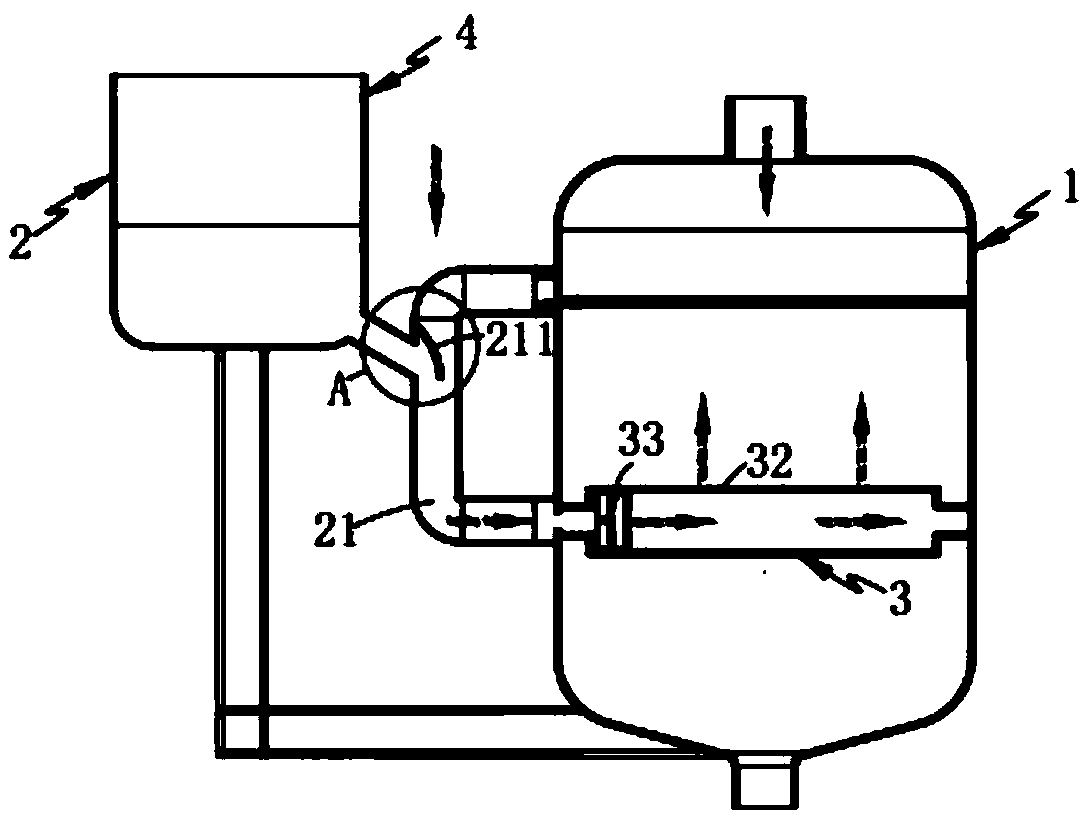

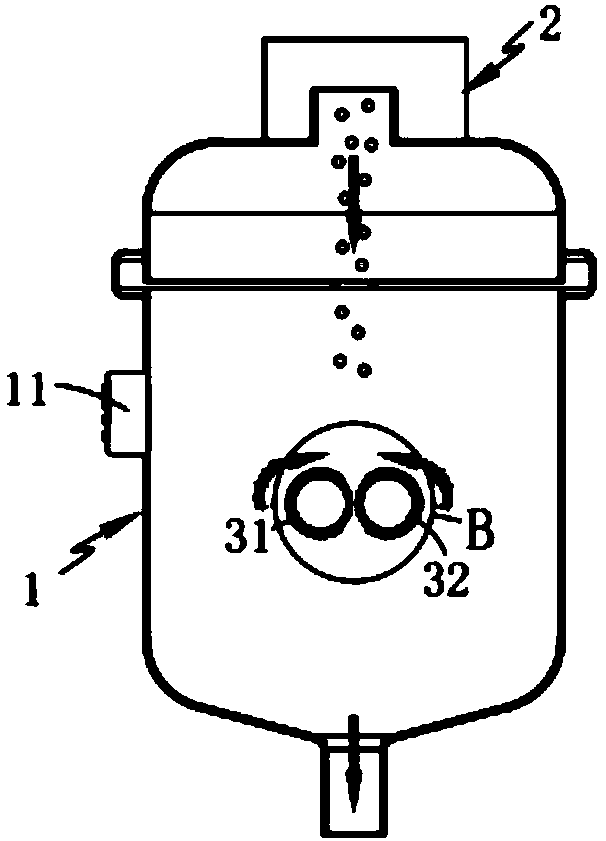

[0027] Such as figure 1 with 2 As shown, a uniform energy-saving melting and mixing device includes a melting bin 1 and a powder bin 4, and also includes:

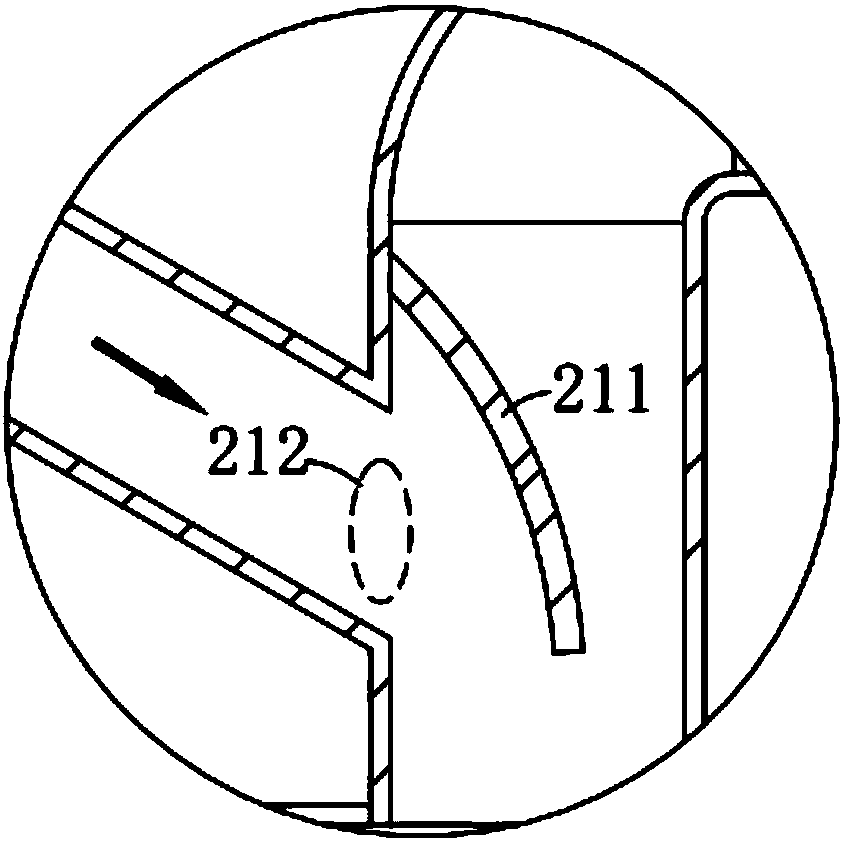

[0028] The powder conveying mechanism 2 includes the air guide pipe 21 installed on the melting chamber 1 and the baffle 211 arranged in the air guide pipe 21. The directional air flow inside the air guide pipe 21 is guided and accelerated by the baffle plate 211 to form a negative pressure zone 212; the negative pressure zone 212 communicates with the powder silo 4;

[0029] Mixing component 3, the mixing component 3 is arranged in the melting chamber 1 and communicated with the air guide pipe 21, after the air flow in the air guide tube 21 conducts quantitative powder introduction, the formed mixed gas is opened in the mixing component Several outlets 321 on the 3 are ejected to form a directional powder flow 322, and the powder flow 322 is arranged in contact with the liquid resin.

[0030] It should be noted that, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com