Petroleum instrument ultrasonic cleaning device

A cleaning device, ultrasonic technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as noise pollution, cleaning machine vibration, reducing cleaning machine stability and service life, etc., to achieve Low cost, reduced contact area, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

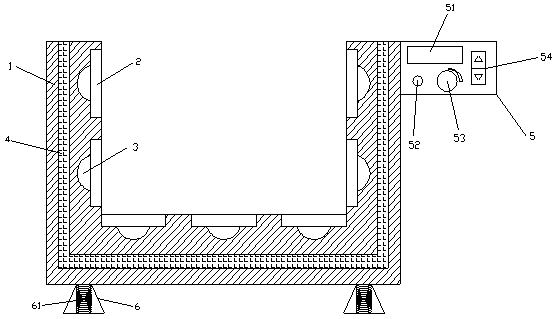

[0012] Such as figure 1 The shown ultrasonic cleaning device for petroleum instruments includes a water tank 1, a vibrating plate 2, and an ultrasonic vibrator 3. The water tank 1 has a U-shaped structure, and the left and right side plates and the bottom plate of the water tank 1 are provided with a vibrating plate 2 , the lower end of the vibrating plate 2 is provided with an ultrasonic vibrator 3, the inside of the water tank 1 is provided with a layer of shock absorbing plate 4, and the outer side of the water tank 1 is provided with an ultrasonic control device 5, and the ultrasonic control device 5 It is electrically connected with the ultrasonic vibrator 3, the lower end of the water tank 1 is provided with a shock-absorbing foot 6, and the ultrasonic control device 5 is provided with a display screen 51, a power switch 52, a timer 53 and a frequency adjustment button 54, A spring 61 is arranged inside the shock-absorbing foot 6 .

[0013] The above descriptions are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com