Automatic assembly machine for iron core assembly

An assembly machine and component technology, applied in the direction of feeding device, storage device, positioning device, etc., can solve the problems of easy bending shaft, bending shaft part, affecting assembly quality, etc., to reduce labor intensity and prevent circumferential deviation The effect of moving and improving assembly efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

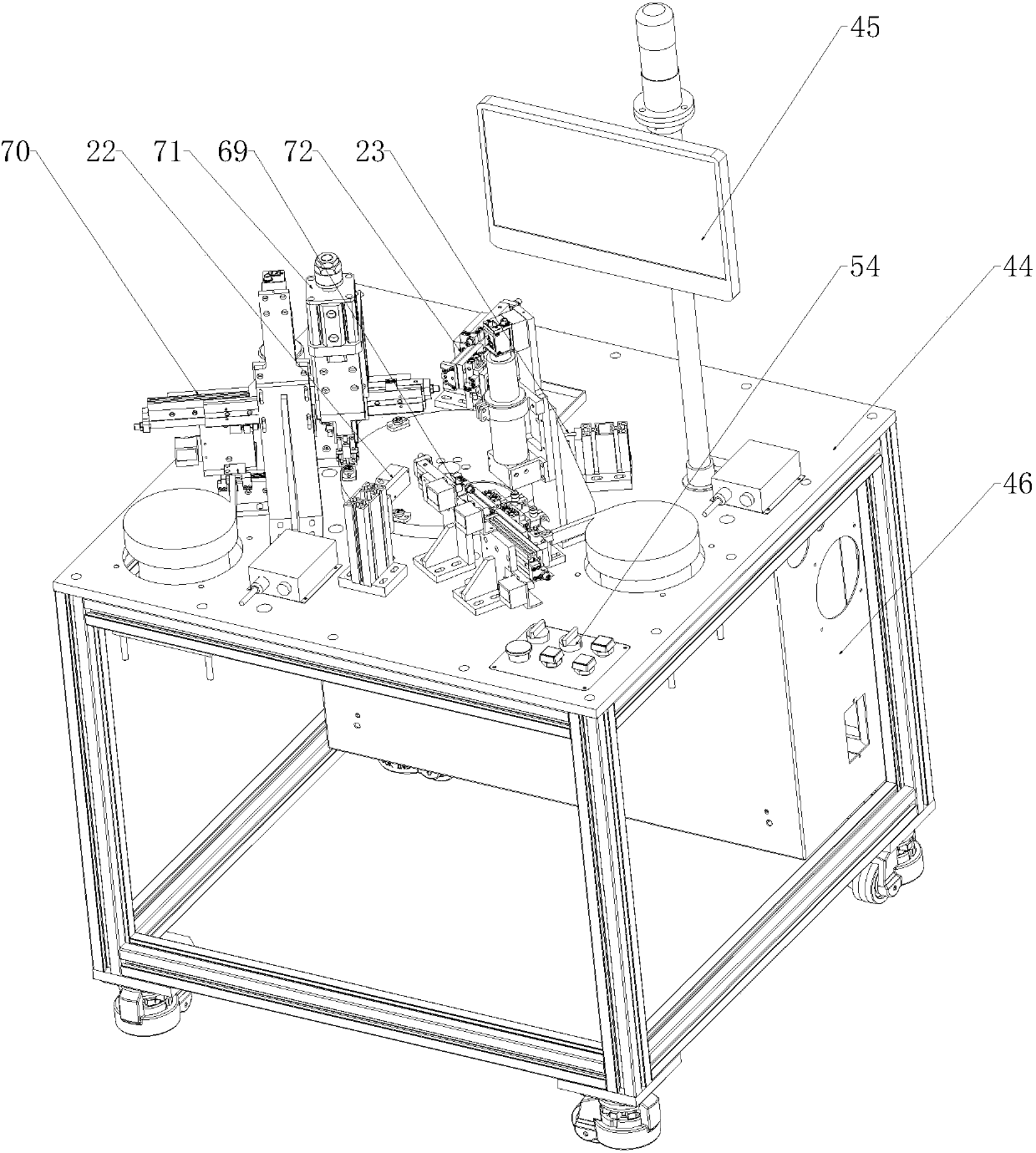

[0075] like Figure 1 to Figure 19 As shown, an automatic assembly machine for iron core components, including a turntable component and an iron core feeding and straightening component, a commutator component feeding and straightening component, a riveting component and a blanking component that are sequentially arranged along the rotation direction of the turntable component;

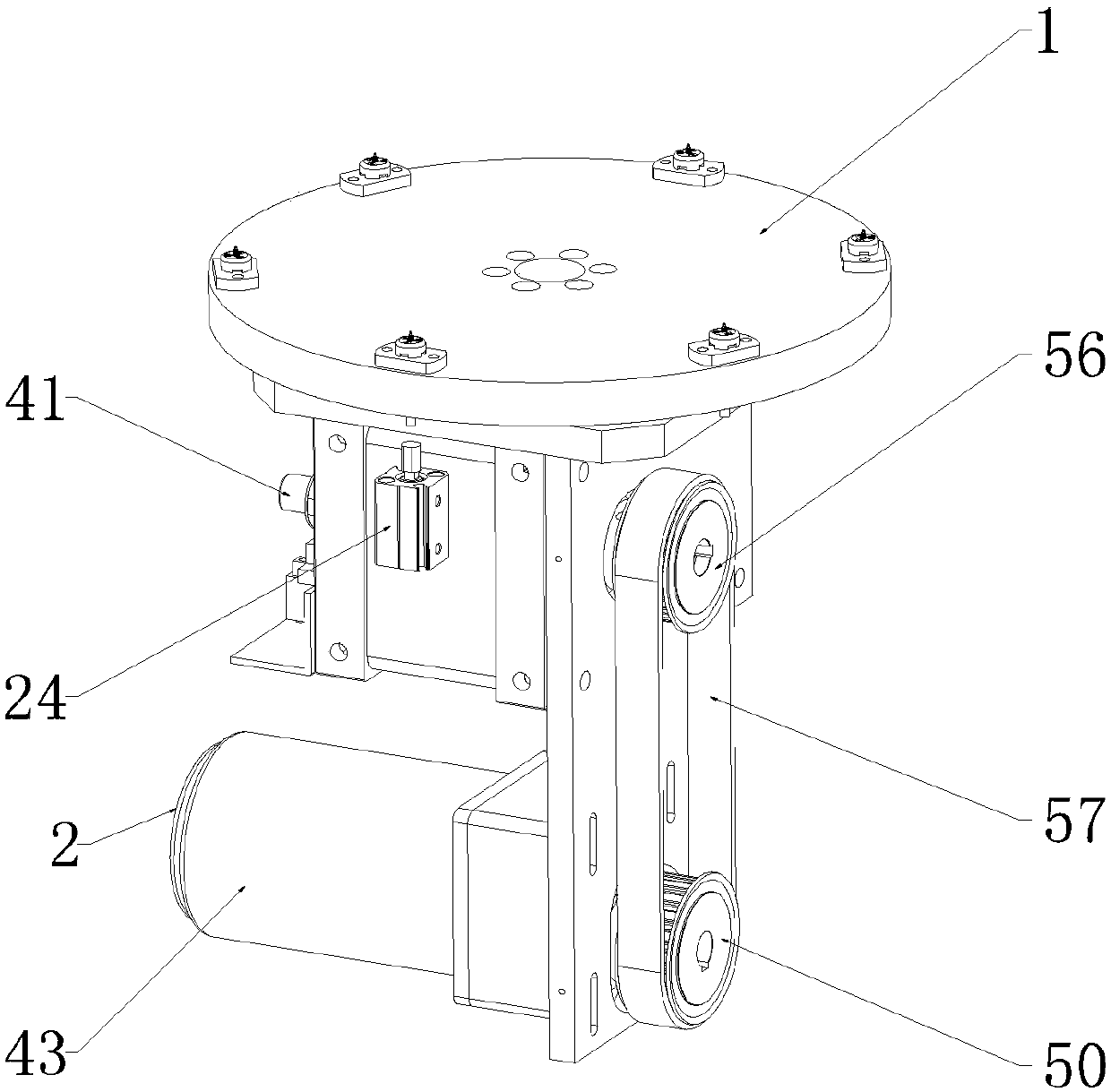

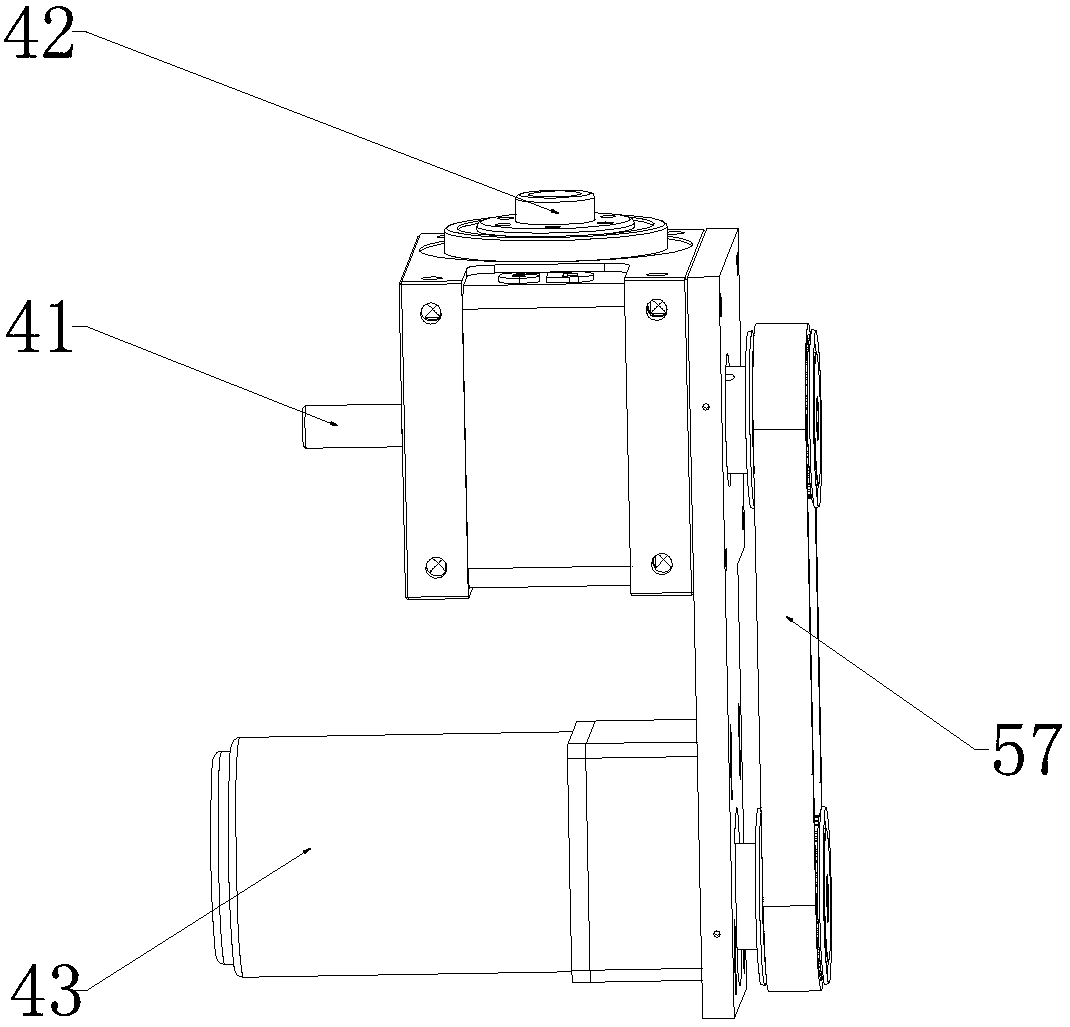

[0076] The turntable assembly includes a turntable 1 and a first drive device 2 for driving the turntable 1 to rotate, and the turntable 1 is provided with several circularly arranged positioning seat assemblies;

[0077]The iron core feeding and correcting assembly includes an iron core correcting part and a suction nozzle transfer part, and the iron core correcting part includes a first straightening table 6, a first image collector 7 located above the first straightening table 6 and a device for driving the first straightening table. 6 The second driving device 8 that rotates, the nozzle transfer p...

Embodiment 2

[0085] This embodiment makes the following further limitations on the basis of Embodiment 1: the positioning seat assembly includes a positioning seat 3, and the positioning seat 3 is provided with a concave positioning groove 4, and the positioning seat 3 is also provided with several circular arrays. And the limiting protrusion 5 extending toward the middle of the positioning groove 4 .

[0086] In this embodiment, for the convenience of processing, several stoppers 65 can be set on the positioning seat 3, the number of stoppers 65 is consistent with the number of iron core winding grooves, and each stopper 65 has the said limiting protrusion part 5 , and the area surrounded by a plurality of blocking pieces 65 forms the positioning groove 4 .

Embodiment 3

[0088] This embodiment makes the following further limitations on the basis of Embodiment 2: the middle part of the positioning seat 3 is provided with a first through hole 27 passing through its upper and lower end surfaces and communicating with the positioning groove 4;

[0089] The positioning seat assembly also includes a hollow supporting base 25, the supporting base 25 is connected to the lower end of the positioning seat 3;

[0090] The top end of the support base 25 is provided with a second through hole 49 communicating with its inner cavity;

[0091] The inner cavity of the support base 25 is provided with a push rod 26 through the second elastic member 72, the lower end of the push rod 26 runs through the bottom end of the support base 25, and the push rod 26 can move upward relative to the support base 25;

[0092] It also includes an eighth driving device 24 arranged below the turntable 1 , the eighth driving device 24 can act on the push rod 26 to move up and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com