Steel structure bridge pavement expansion joint filling and covering device

A technology of covering devices and expansion joints, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge vibration, rubber belt damage, bridge deck water leakage and other problems, so as to prolong the service life, avoid contact extrusion, avoid The effect of excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

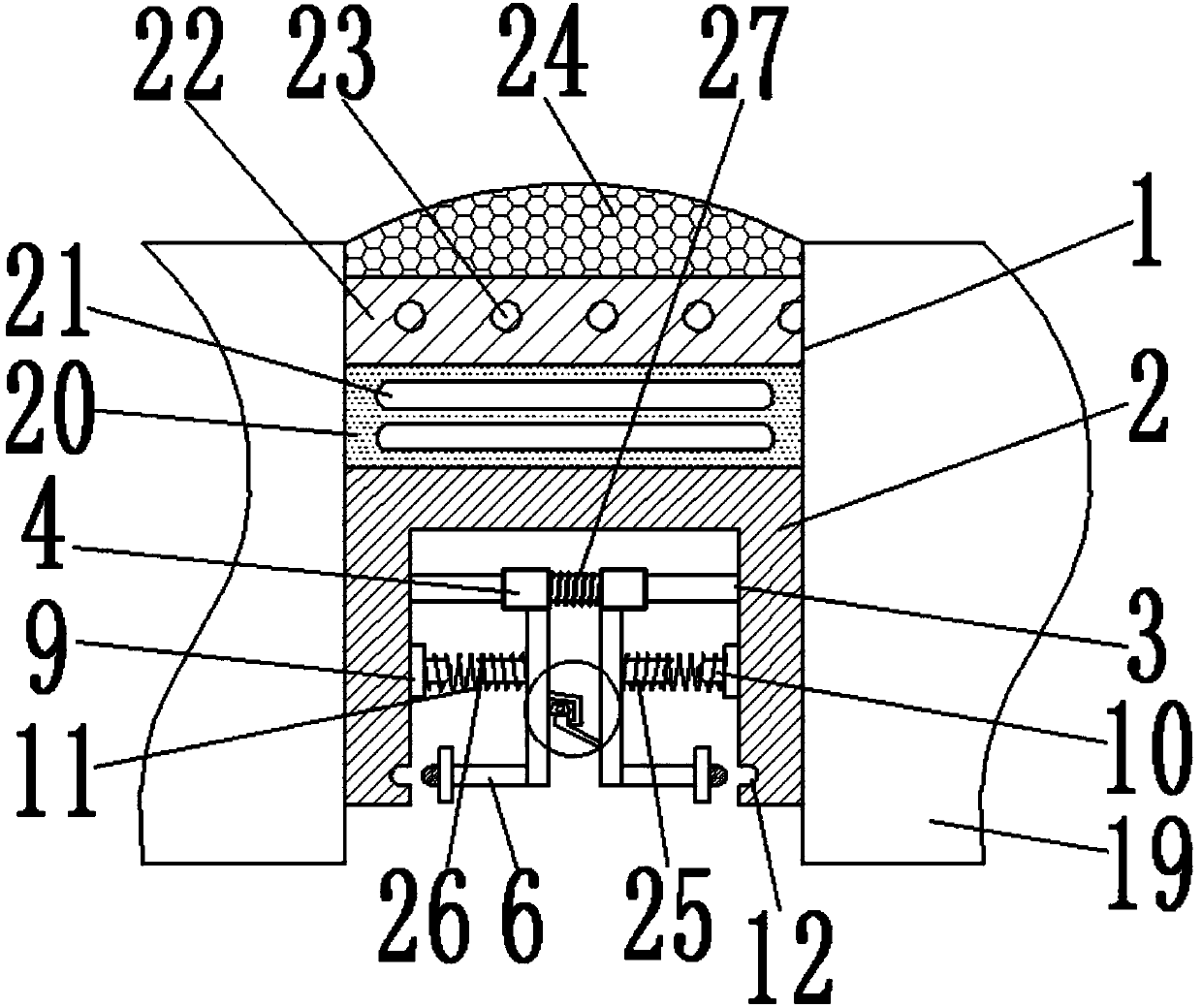

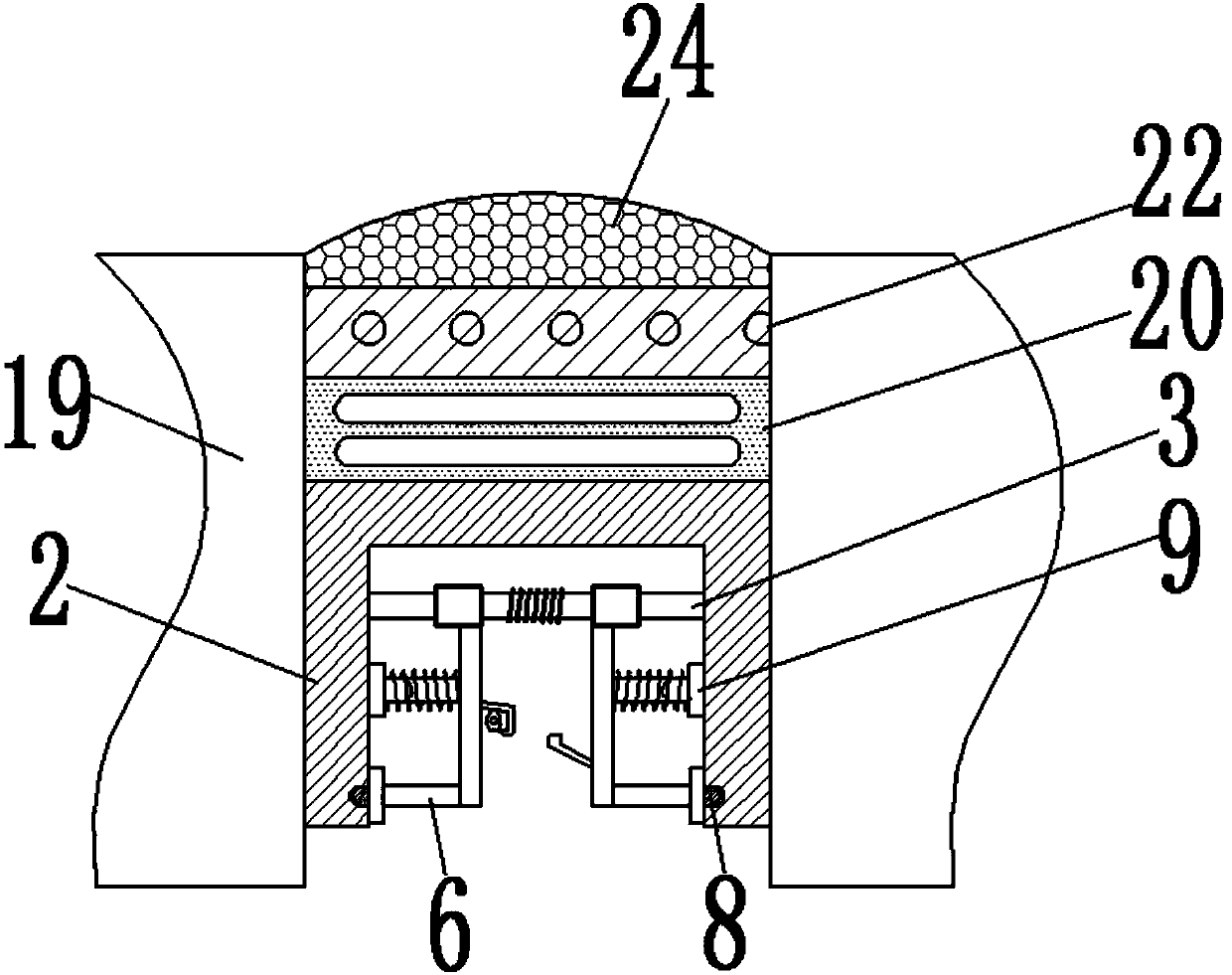

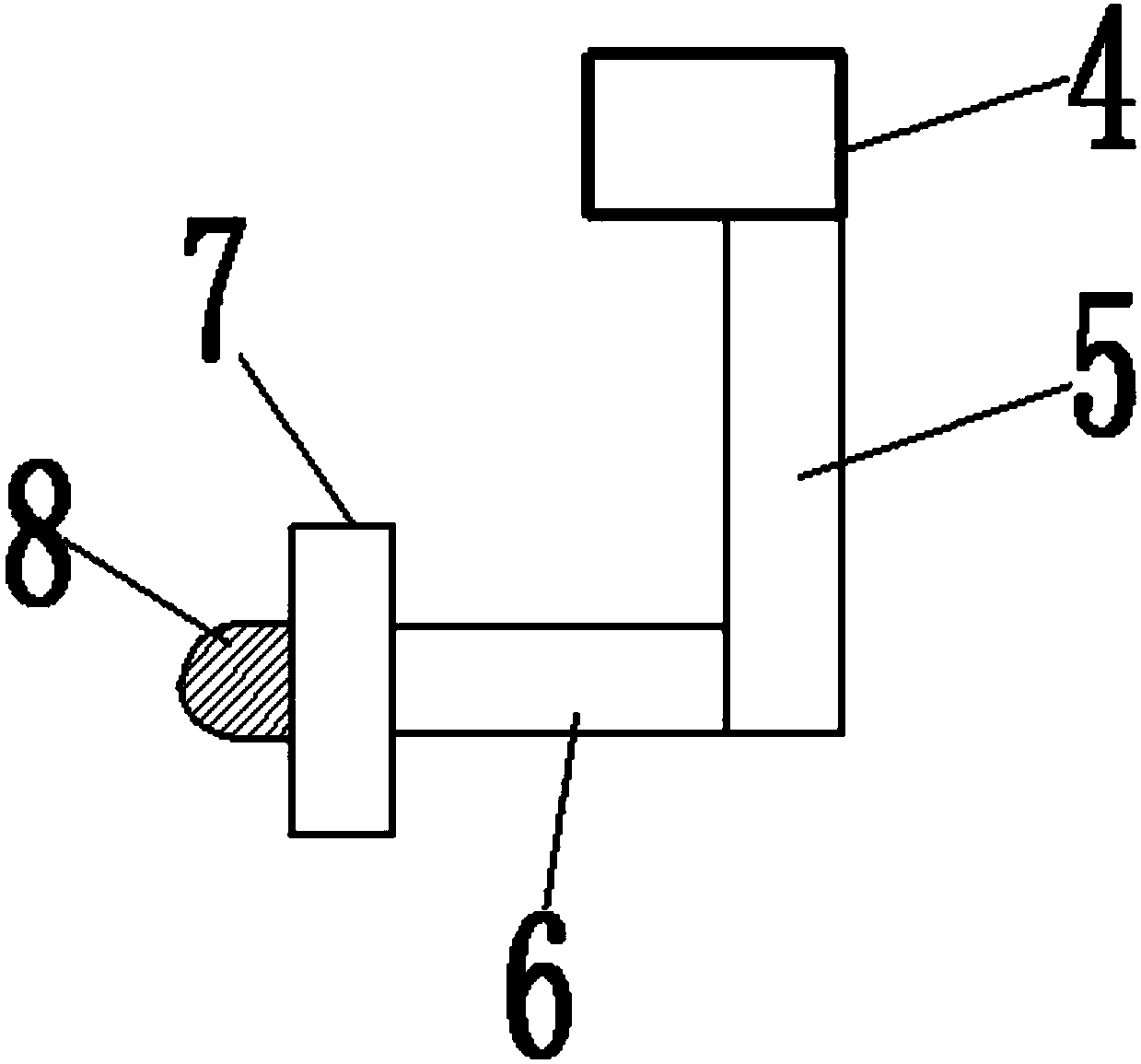

[0022] See Figure 1-4 , A steel structure bridge pavement expansion joint filling and covering device, comprising an expansion joint 1 and a hard rubber base layer 2; the two sides of the expansion joint 1 are a road base 19; the hard rubber base layer 2 is arranged inside the expansion joint 1 The bottom of the hard rubber base layer 2 is an inverted U-shaped structure, with support rods 3 arranged in the grooves; both ends of the support rods 3 are fixed on the two grooves of the hard rubber base layer 2. Two sleeves 4 are arranged on the side inner wall; the lower end of the sleeve 4 is connected with a vertical rod 5; the vertical rod 5 is connected with a cross rod 6 in the direction of the inner wall of the groove of the hard rubber base layer 2; The end of the crossbar 6 is provided with a stopper 7; the front end of the stopper 7 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com