Long-life centrifugal pump cover

A centrifugal pump, long-life technology, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of reduced service life and stability, friction between particles and mechanical seals, mechanical seal damage, etc., to improve service life , enhance temperature resistance, and improve the effect of trial life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

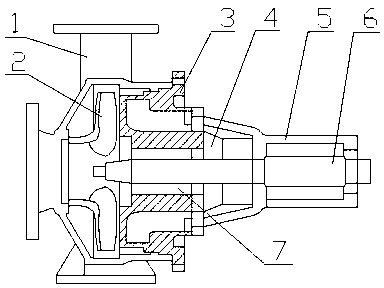

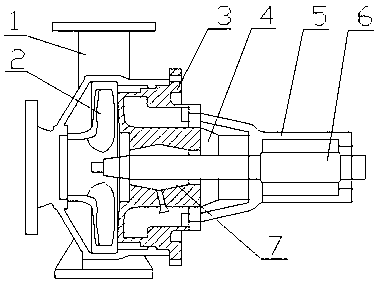

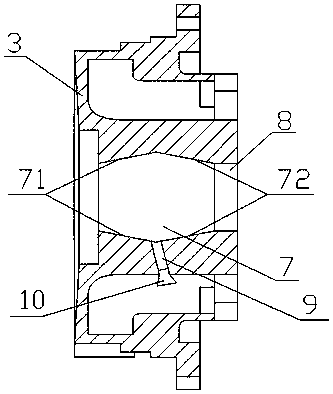

[0021] A pump cover of a long-life centrifugal pump, including a central through hole 8 provided on the pump cover body 3, and the side of the central through hole 8 facing the pump body 1 of the centrifugal pump is provided with a The mechanical seal cavity 7 is characterized in that the inner wall of the mechanical seal cavity 7 is divided into a left inner wall 71 and a right inner wall 72, and the cross-sectional shape of the mechanical seal cavity 7 composed of the left inner wall 71 and the right inner wall 72 is spinning. Conical, the intersection of the bottom of the left inner wall 71 and the right inner wall 72 is provided with a through-hole 9 that passes through the pump cover body 3, and the bottom of the through-hole 9 is provided with a sealing plug 10. Both the left inner wall 71 and the right inner wall 72 are coated with anti-corrosion and wear-resistant paint.

[0022] Further, the left inner wall 71 and the right inner wall 72 incline at the same angle, and...

Embodiment 2

[0030] A pump cover of a long-life centrifugal pump, including a central through hole 8 provided on the pump cover body 3, and the side of the central through hole 8 facing the pump body 1 of the centrifugal pump is provided with a The mechanical seal cavity 7 is characterized in that the inner wall of the mechanical seal cavity 7 is divided into a left inner wall 71 and a right inner wall 72, and the cross-sectional shape of the mechanical seal cavity 7 composed of the left inner wall 71 and the right inner wall 72 is spinning. Conical, the intersection of the bottom of the left inner wall 71 and the right inner wall 72 is provided with a through-hole 9 that passes through the pump cover body 3, and the bottom of the through-hole 9 is provided with a sealing plug 10. Both the left inner wall 71 and the right inner wall 72 are coated with anti-corrosion and wear-resistant paint.

[0031] Further, the left inner wall 71 and the right inner wall 72 incline at the same angle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com