Air-leaking-reducing anti-ash-blocking system and method for rotary air preheater

An air preheater, rotary technology, applied in the direction of combustion method, air induction, lighting and heating equipment, etc., can solve problems such as blockage and large air leakage, increased fan power consumption, increased operating costs, etc., to reduce low temperature Corrosion and dust accumulation, avoiding the increase of fan power consumption, and reducing the effect of carrying air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

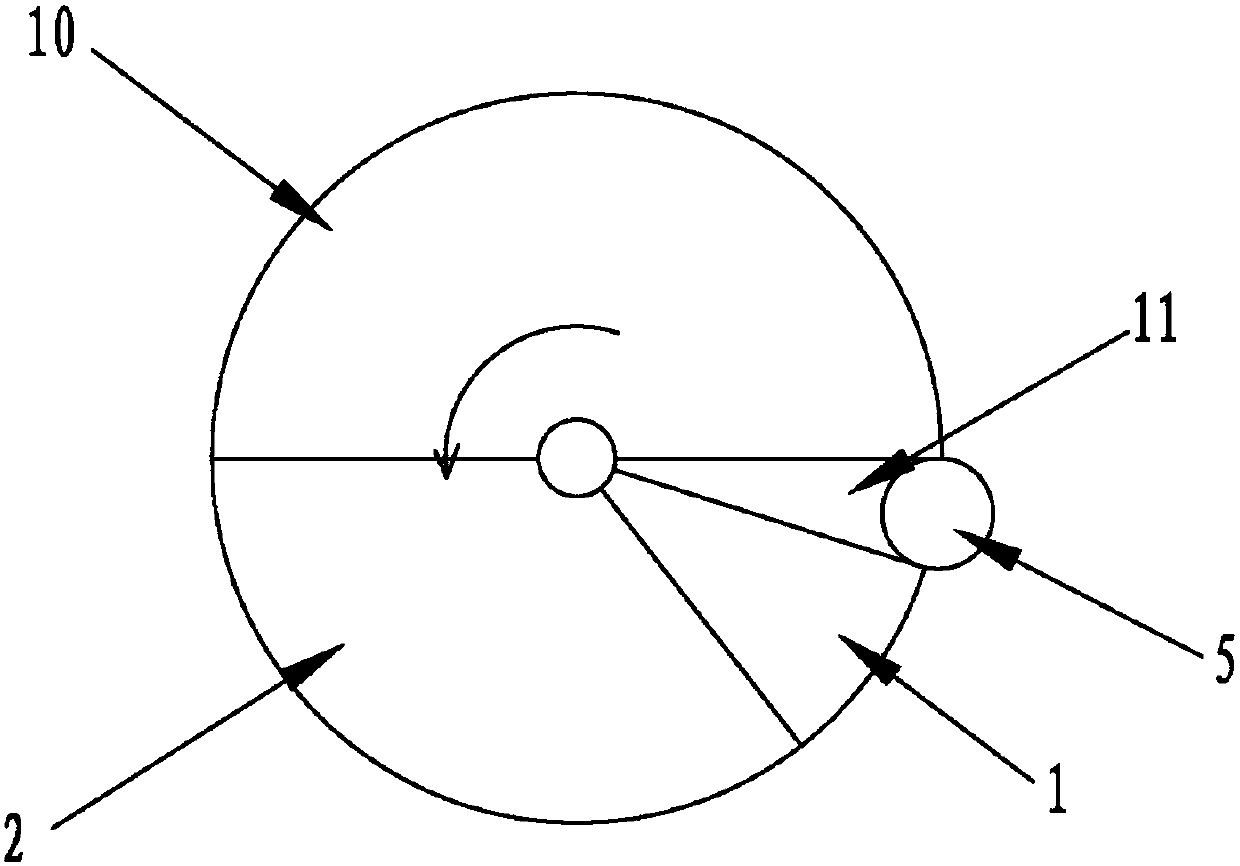

[0020] Such as figure 1 , image 3 As shown, Embodiment 1 of the air leakage and anti-clogging system of the rotary air preheater of the present invention, wherein the rotary air preheater is internally provided with a flue gas bin 10, a primary air bin 1, and a secondary air bin 2 , Heat storage element. Embodiment 1 of the air leakage and anti-blocking ash system of the rotary air preheater of the present invention, wherein the flue gas bin 10, the secondary air bin 2, and the primary air bin 1 are along the direction of the arrow (i.e. figure 1 Arranged in the counterclockwise direction), the heat storage element is arranged in the direction of the arrow (ie figure 1 (shown counterclockwise), that is, the heat storage element passes through the flue gas bin 10, the secondary air bin 2, and the primary air bin 1 in sequence.

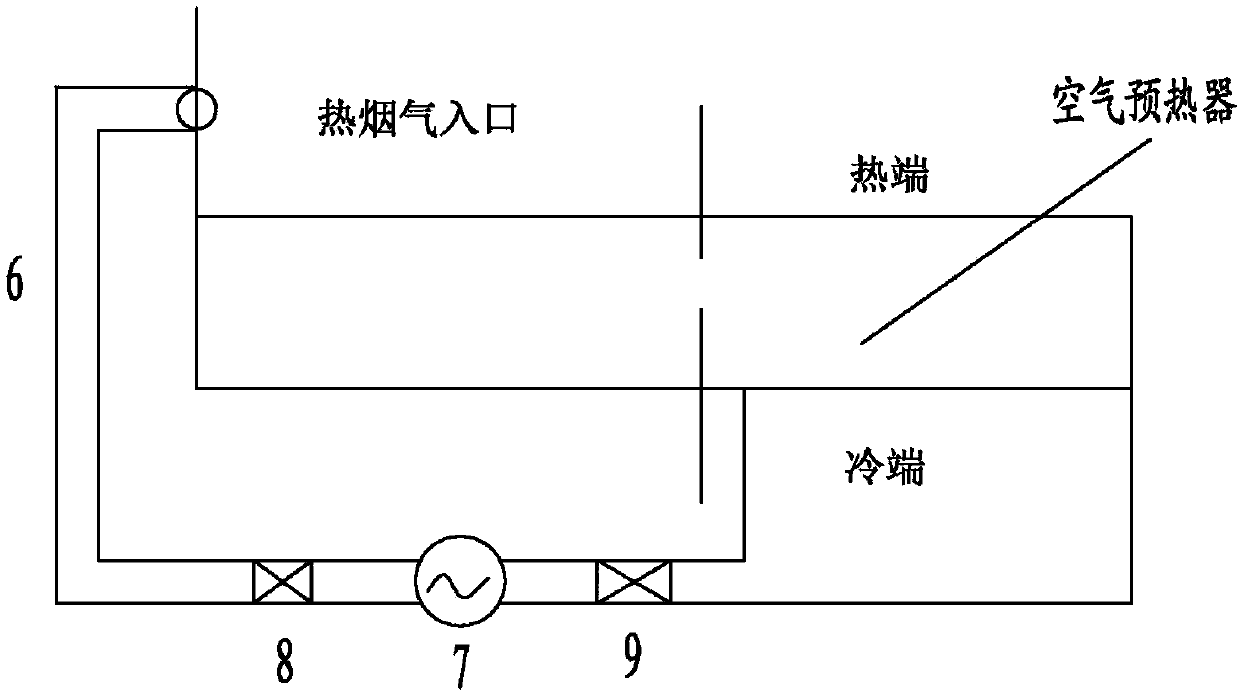

[0021] The air leakage and anti-blocking ash system of the rotary air preheater includes a flue gas recirculation sub-bin 11 and a flue gas recircu...

Embodiment 2

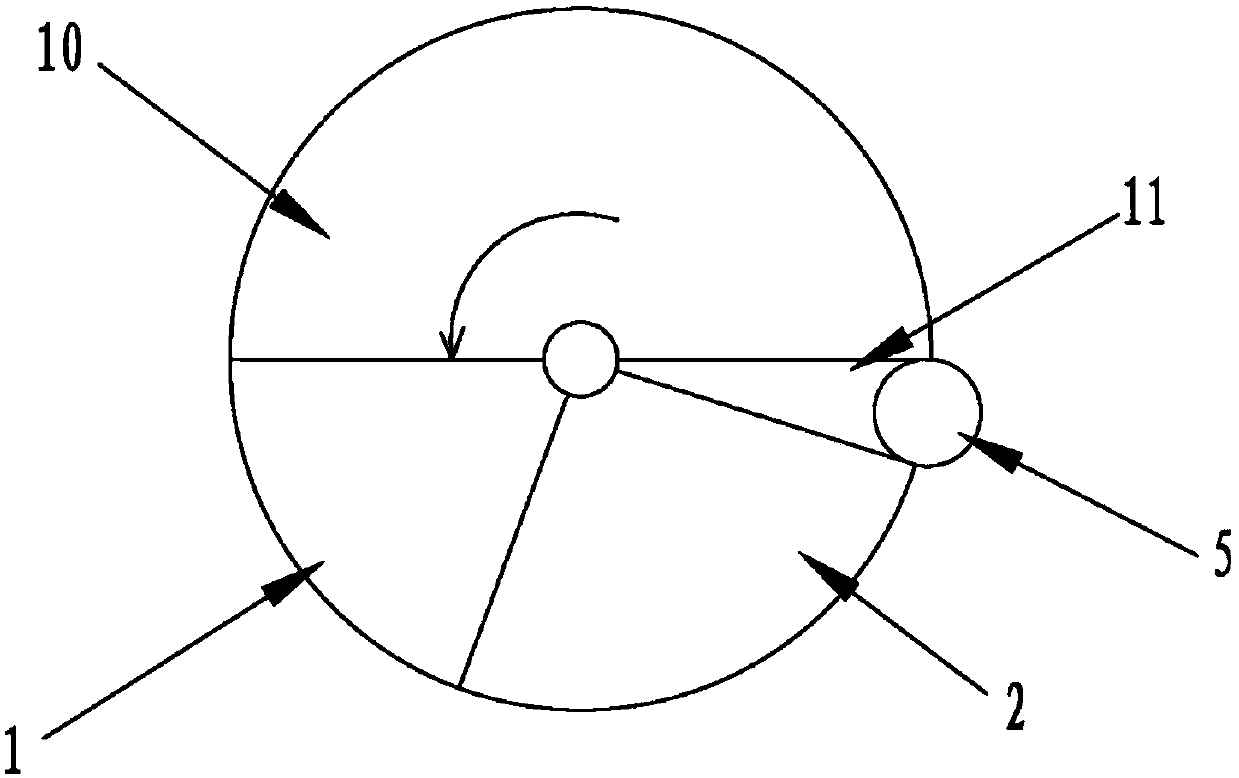

[0026] Such as figure 2 As shown, Embodiment 2 of the air leakage and anti-blocking ash system of the rotary air preheater of the present invention, wherein the rotary air preheater is equipped with a flue gas bin 10, a primary air bin 1, and a secondary air bin 2 , Heat storage element. Embodiment 2 of the air leakage and anti-blocking ash system of the rotary air preheater of the present invention, wherein the flue gas bin 10, the primary air bin 1, and the secondary air bin 2 are arranged along the direction of the arrow (i.e. figure 1 Arranged in the counterclockwise direction), the heat storage element is arranged in the direction of the arrow (ie figure 1 (shown counterclockwise), that is, the heat storage element passes through the flue gas bin 10, the primary air bin 1, and the secondary air bin 2 in sequence. The air leakage and anti-blocking ash system of the rotary air preheater includes a flue gas recirculation sub-bin 11 and a flue gas recirculation system 5. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com