Detection device for detecting stress of pantograph on overhead line system

A detection device and catenary technology, which is applied in the field of image recognition, can solve problems such as large structure, large catenary lift, pantograph-catenary accidents, etc., and achieve the effect of simple system structure, convenient installation and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

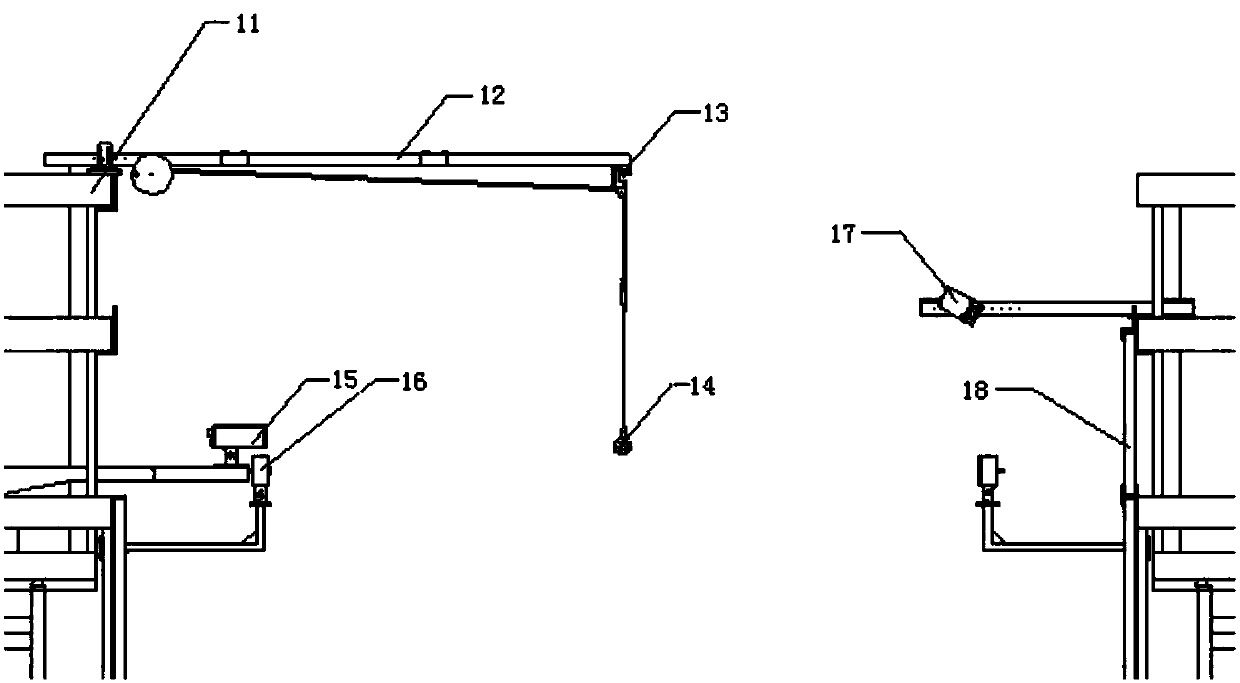

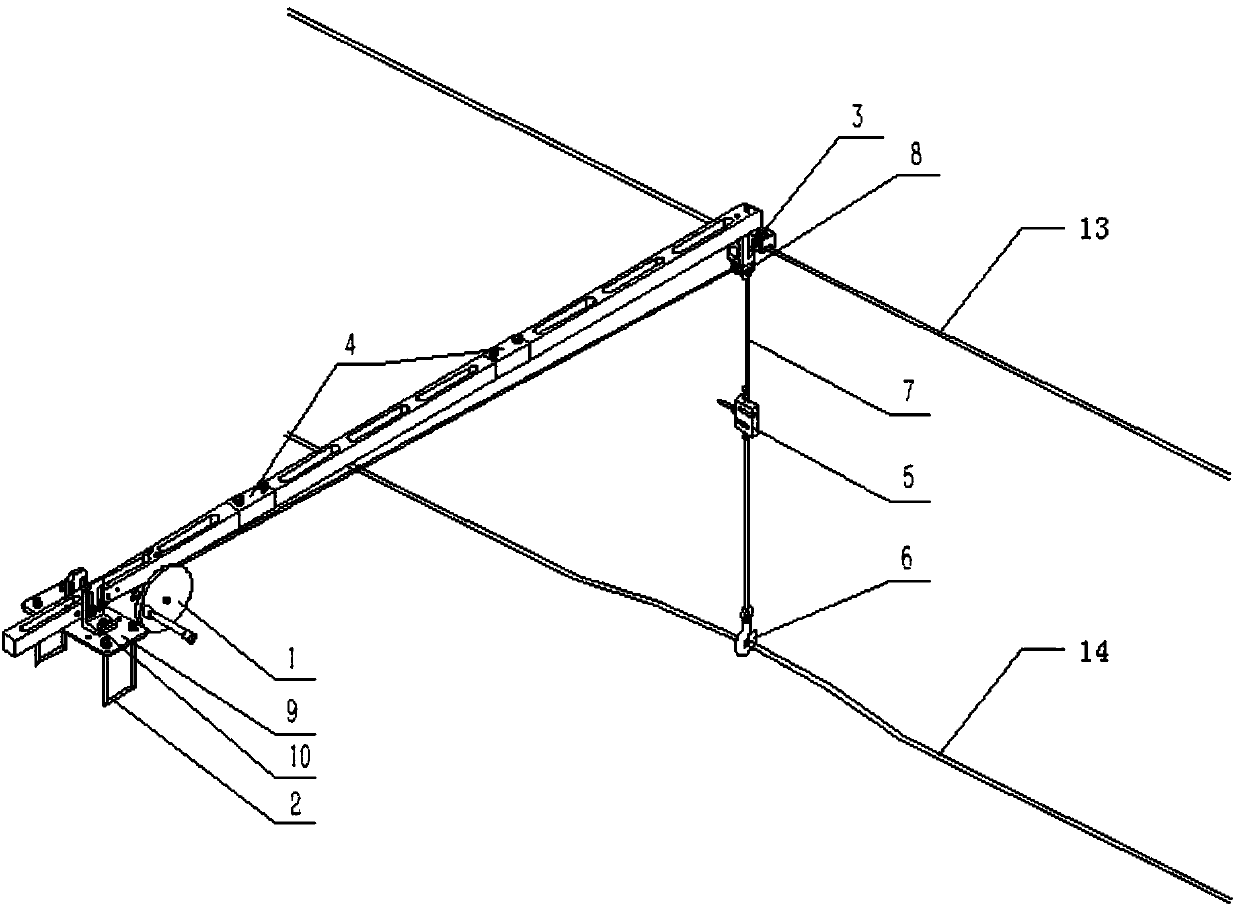

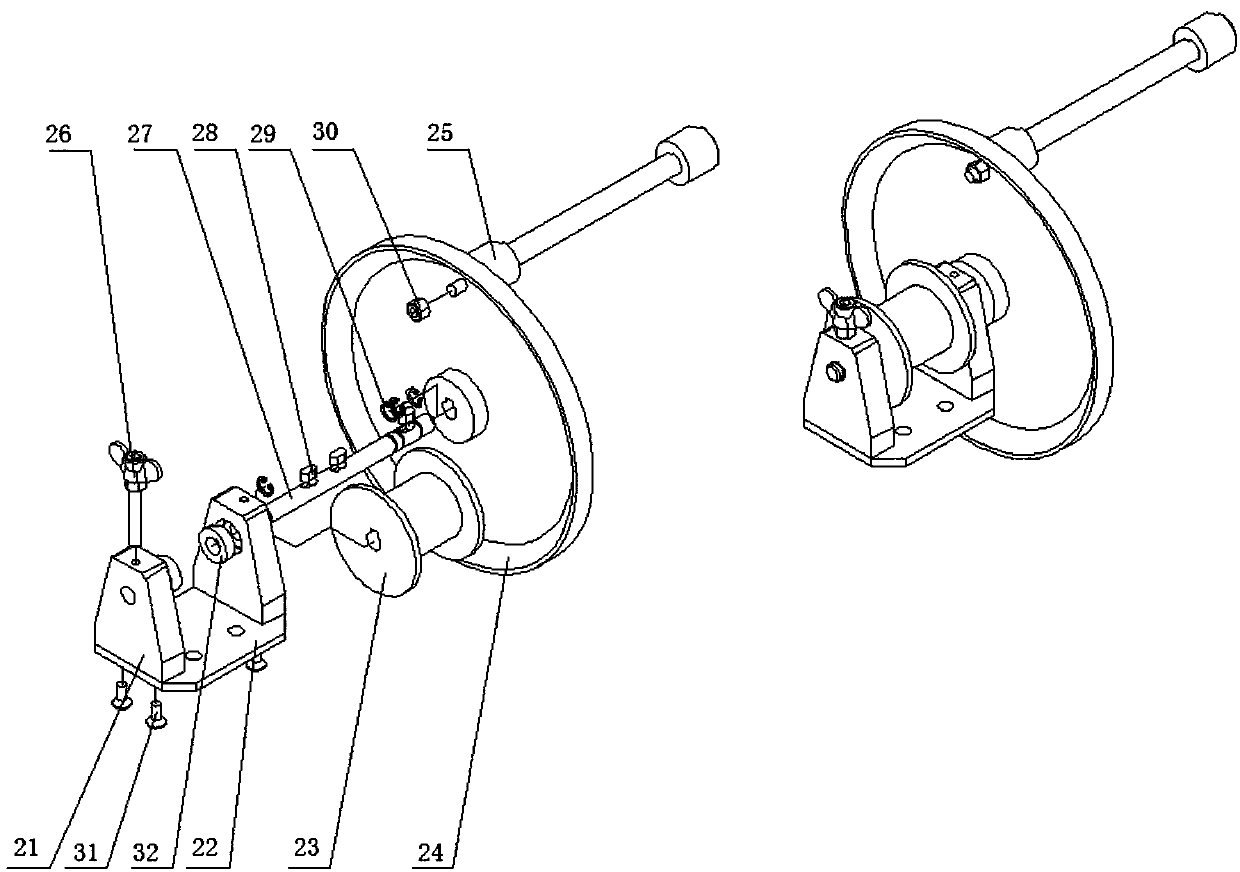

[0033] The detection device of the pantograph to the catenary stress of the present embodiment, the system includes a camera, a white background board, a background board flashlight, a trigger sensor, and a tension detection device. The camera and the white background board are installed on the same horizontal plane as the catenary, and the trigger sensor is installed on About 100mm directly below the camera, see Figure II Connect the three support frames with the insulating adapter 4, fix the wire clamp 3 on the top of the right support frame, the wire clamp 3 contains bearings and pulleys, and the pulley part is made of nylon material; fix a set of fixed pulleys 8 on the top of the right support frame ;The winding device 1 is installed on the left support frame, and the winding device 1 contains a brake fastening bolt, which is used to brake the rope 7 in time to ensure the accuracy of the pulling force when the camera is shooting; the hook 6, the pressure sensor 5 , the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com