Arc load switch

A load switch and arc extinguishing technology, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of large size, roughness, and poor arc extinguishing performance, and achieve simple overall structure and reliable conductive connection , Improve the effect of arc extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

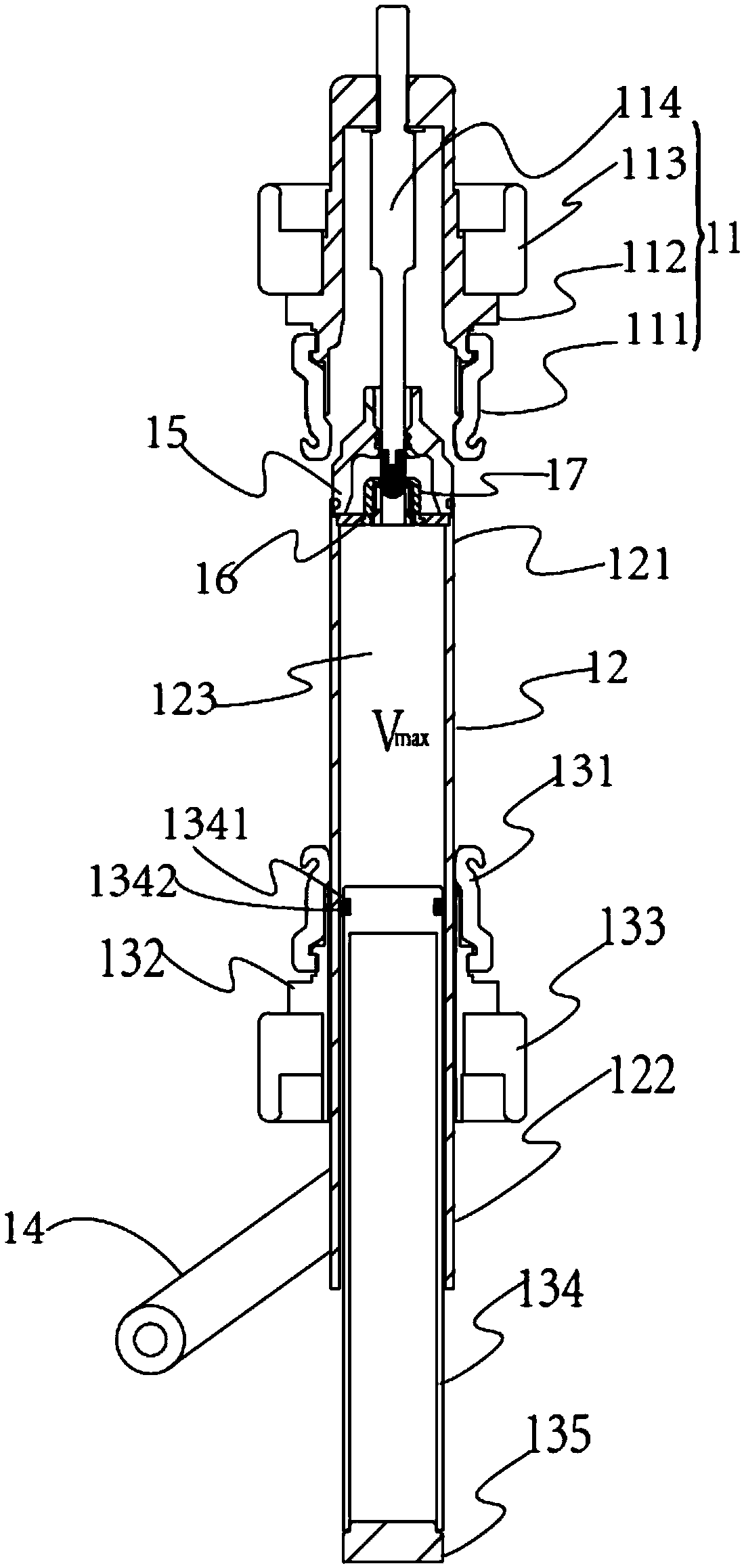

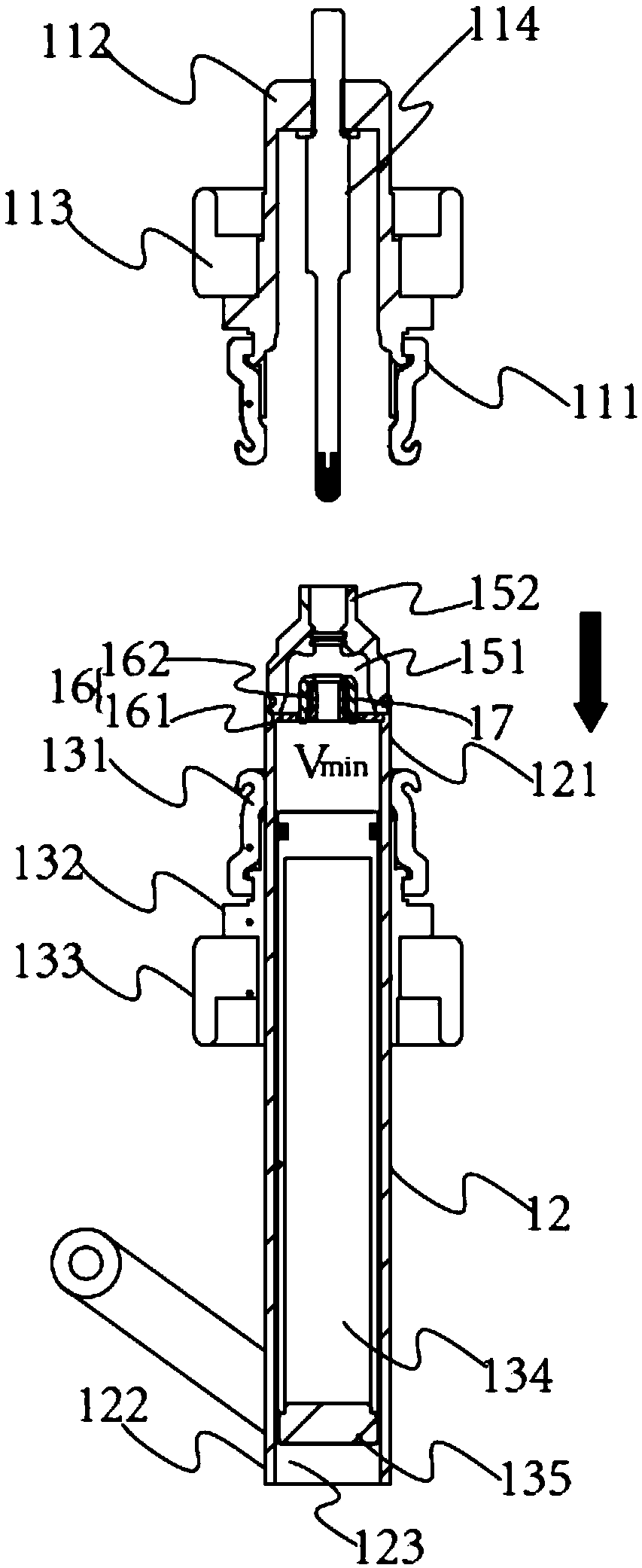

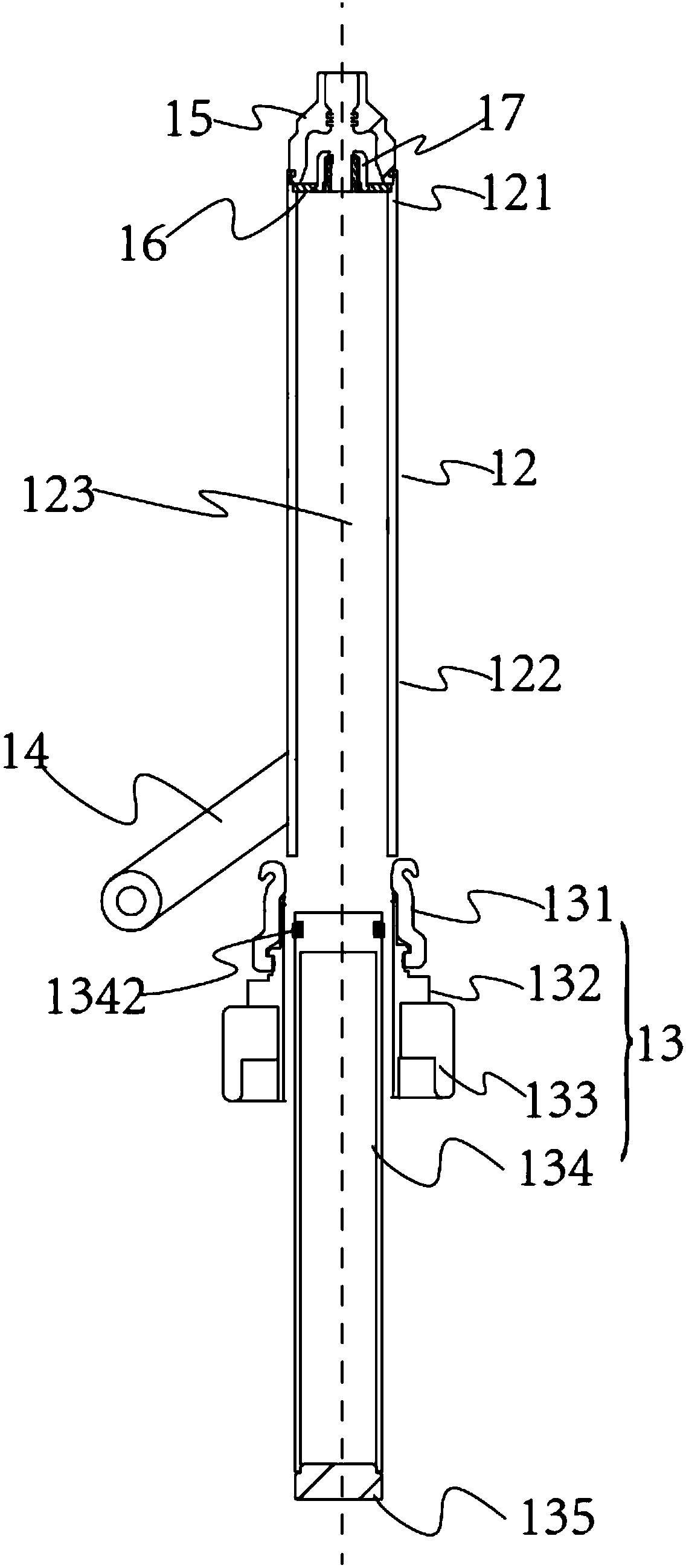

[0047] figure 1 It is a sectional view of the arc extinguishing load switch in the closing position according to the first embodiment of the present invention; figure 2 for figure 1 The sectional view of the arc extinguishing load switch in the shown embodiment in the opening position; image 3 for figure 1 A schematic structural diagram of a state in which the conductive rod of the switch in the illustrated embodiment is separated from the second conductive end.

[0048] Such as Figure 1-3 As shown, the arc extinguishing load switch includes a first conductive terminal 11 and a second conductive terminal 13 (see image 3 ) and a conductive rod 12 driven to move. Through the movement of the conductive rod 12, the first conductive end 11 and the second conductive end 13 can be electrically connected or disconnected, so as to realize the closing and opening operations of the switch.

[0049] in figure 1 An example is the closed state, the first end 121 of the conductive...

Embodiment 2

[0065] Figure 4 It is a schematic diagram of the enlarged structure of the switch air nozzle and the moving arc contact in the second preferred embodiment of the present invention; Figure 5A It is a schematic cross-sectional view of the moving arcing contact of the switch according to the second preferred embodiment of the present invention. Figure 5B It is a schematic plan view of the moving arcing contact of the switch according to the second preferred embodiment of the present invention.

[0066] Figure 4 , Figure 5A , Figure 5B Corresponding to the second embodiment of the present invention, in this embodiment, the optimization and improvement are mainly carried out on the air flow nozzle 15 and the moving arc contact 16 , and other parts refer to the description of the first embodiment, which will not be described again. The traditional airflow nozzle either has no cavity for accumulating airflow at all, or does not do any research and design on the flow field o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com