Novel kettle type reboiler and manufacturing process thereof

A reboiler and kettle-type technology, which is applied in the field of new kettle-type reboiler and its manufacturing process, can solve the problem of insufficient liquid storage space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

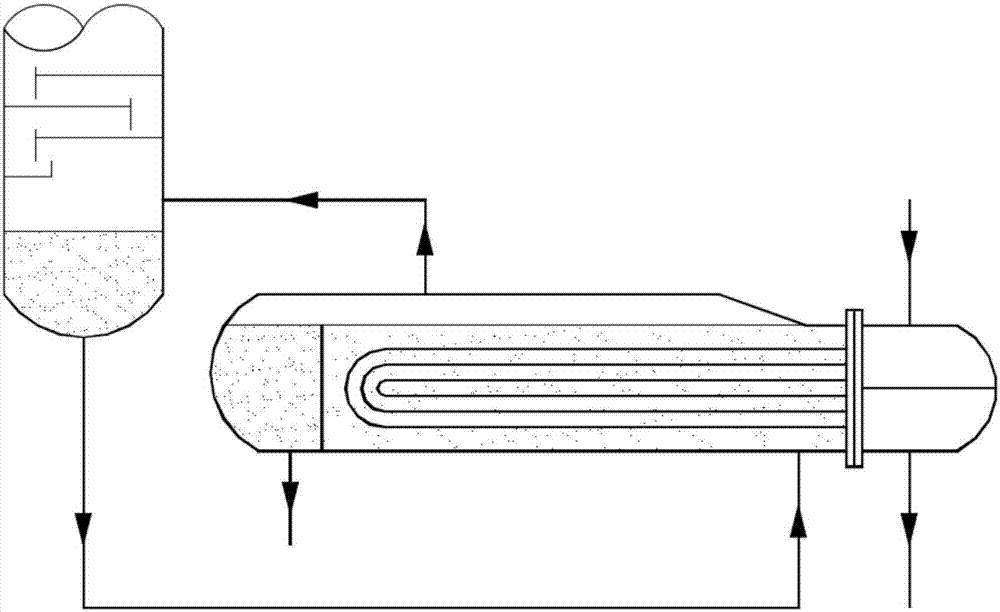

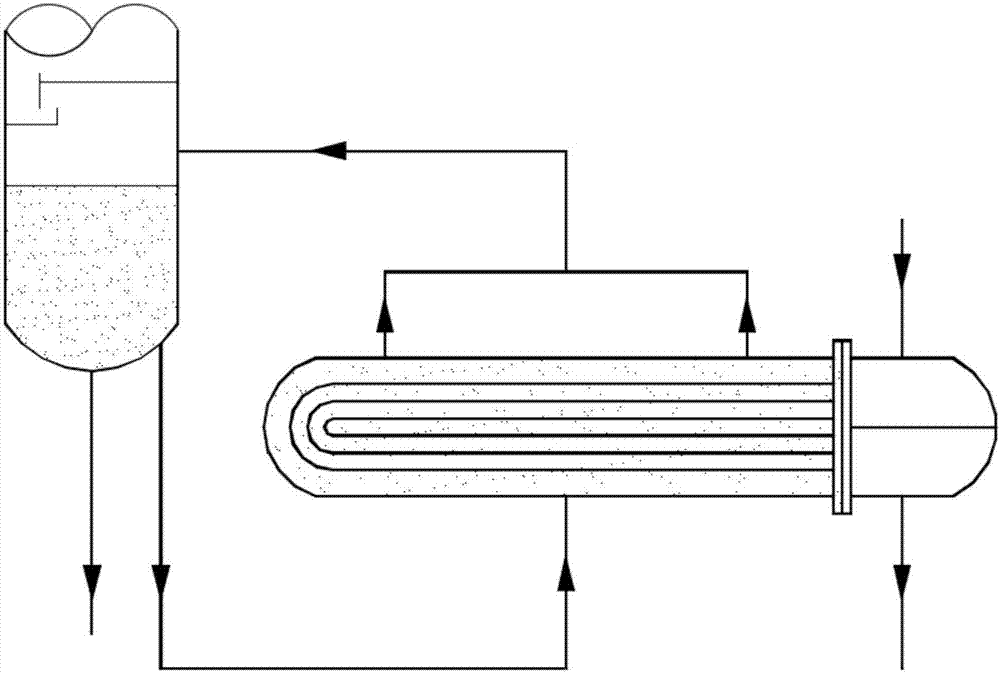

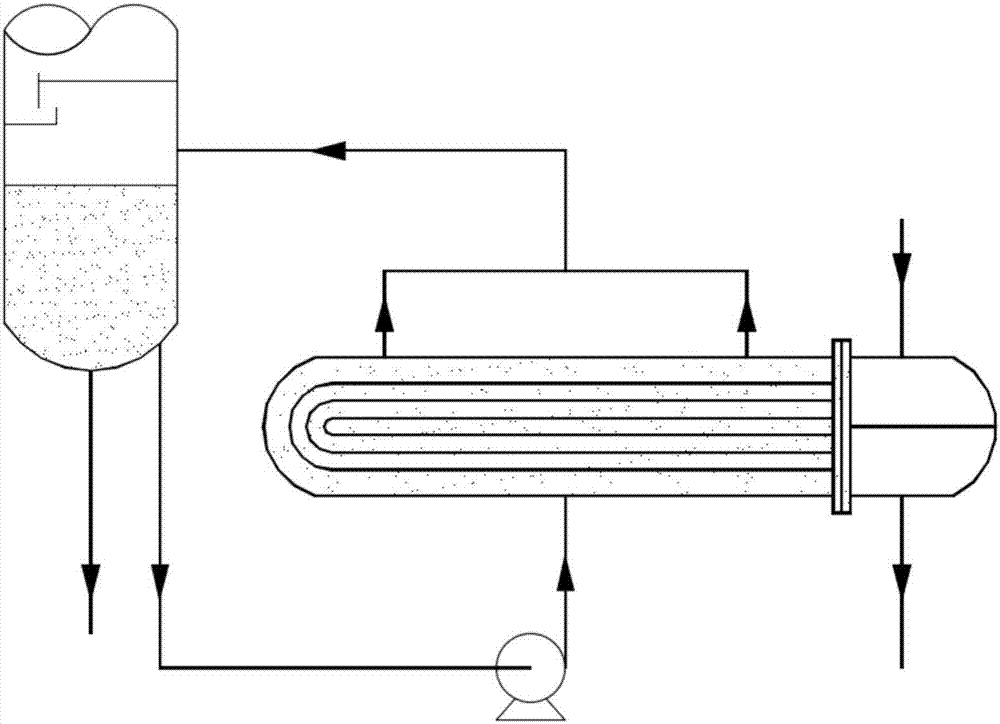

[0047] A novel kettle-type reboiler, the novel kettle-type reboiler is composed of a shell assembly, a tube bundle assembly, and a pipe box assembly, wherein the shell assembly includes a shell 1, and the shell 1 is Horizontal storage tank, the head end of the shell 1 is provided with a shell interface flange 2, the shell 1 is provided with an inner cylinder plate 4, and the inner cylinder plate 4 divides the shell 1 into an inner cavity and a The outer cavity communicates with the outer cavity, and the inner cavity is provided with a support guide rail 5 and a shock absorber 35. The tube bundle assembly includes a U-shaped heat exchange tube bundle 32, and the U-shaped heat exchange tube bundle 32 is Under the support and stabilization of the support plate 33, the expansion joint is installed on the fixed tube plate 31 of the tube bundle. The U-shaped heat exchange tube bundle 32 and the support plate 33 are arranged in the inner cavity formed by the inner cylinder plate 4 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com