Automatic pipe expanding machine

A pipe expander and automatic technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low manual operation efficiency, misalignment of pipes, time-consuming and laborious, etc., to achieve simple structure, avoid pipe stuck, Anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1

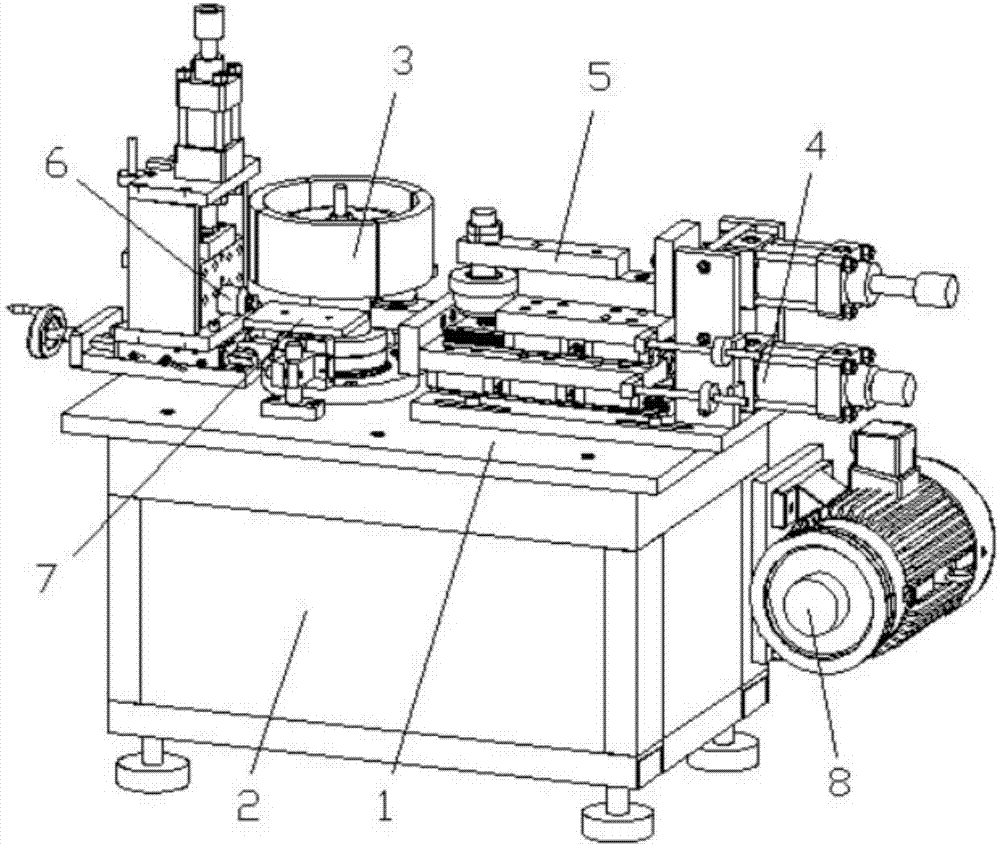

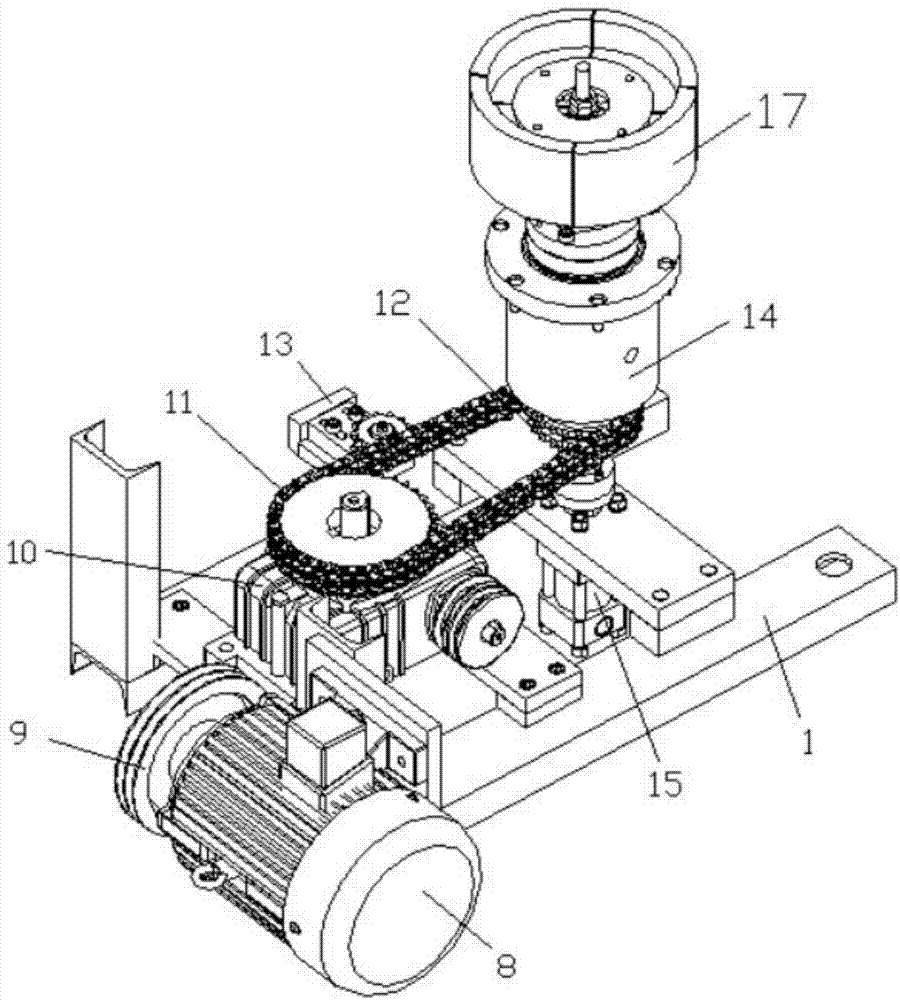

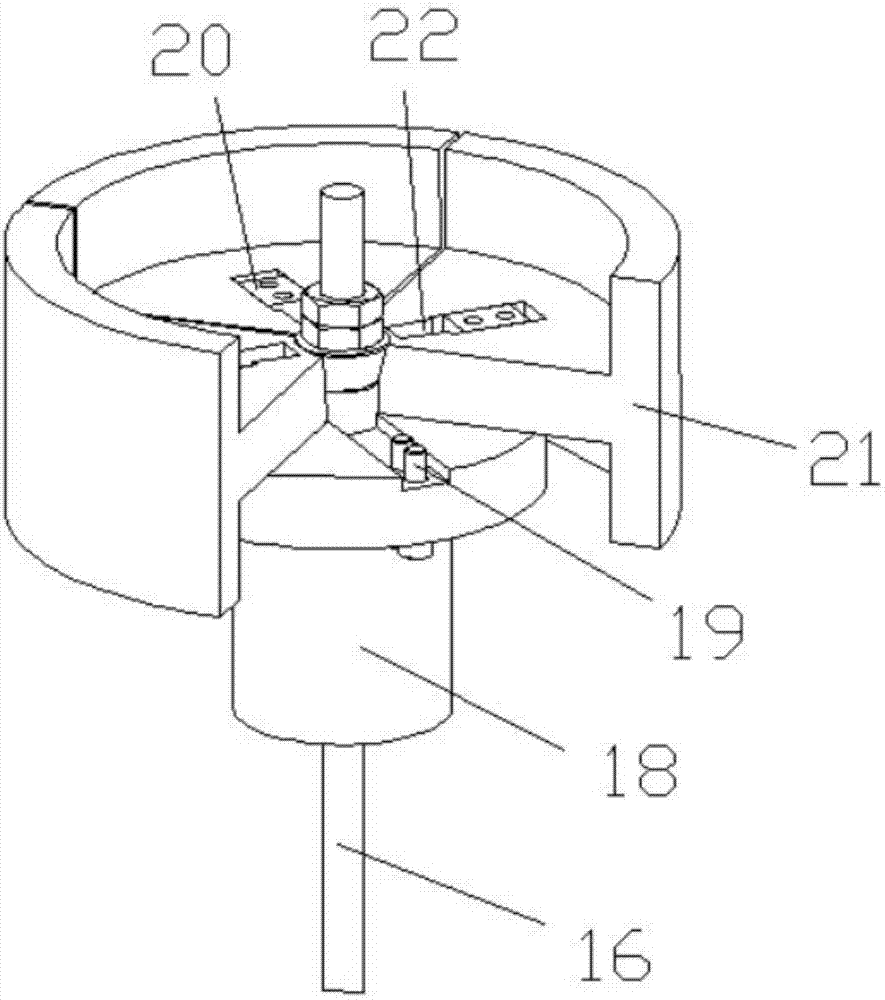

[0034] Such as Figure 1-Figure 8 As shown, the specific structure of the present invention is: an automatic pipe expanding machine, which includes a frame 1 and a power distribution control box 2. The frame 1 is provided with a pipe expansion loading device 3, and the pipe expansion The material loading device 3 includes a material loading tube expander 17 matched with a tube. A material loading shaft 16 is connected to the lower part of the material loading tube expander 17 and the material loading shaft 16 is connected with a sprocket 12 and a chain 11 The output shaft of the power commutator 10, the input shaft of the power commutator 10 is connected to the tube expansion rotating motor 8 through the transmission wheel 9 and the transmission belt, and the material carrying tube expander 17 includes a material carrying shaft 16 connected The material-carrying swivel 18, the material-carrying swivel 18 is evenly provided with a material-carrying fixed slide b...

Example Embodiment

[0042] Example 2

[0043] Such as Figure 1-Figure 7 , Picture 9 As shown, the specific structure of the present invention is: an automatic pipe expanding machine, which includes a frame 1 and a power distribution control box 2. The frame 1 is provided with a pipe expansion loading device 3, and the pipe expansion The material loading device 3 includes a material loading tube expander 17 matched with a tube. A material loading shaft 16 is connected to the lower part of the material loading tube expander 17 and the material loading shaft 16 is connected with a sprocket 12 and a chain 11 The output shaft of the power commutator 10, the input shaft of the power commutator 10 is connected to the tube expansion rotating motor 8 through the transmission wheel 9 and the transmission belt, and the material carrying tube expander 17 includes a material carrying shaft 16 connected The material-carrying swivel 18, the material-carrying swivel 18 is evenly provided with a material-carrying...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap